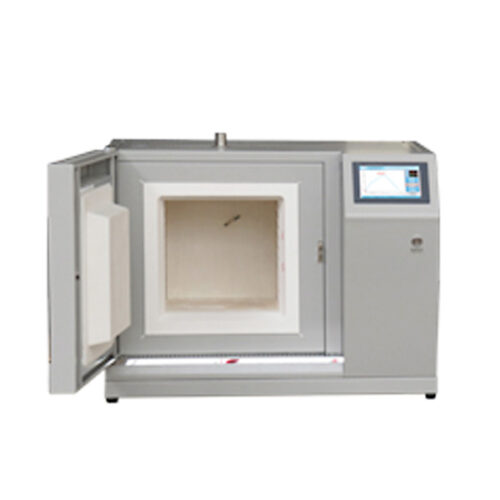

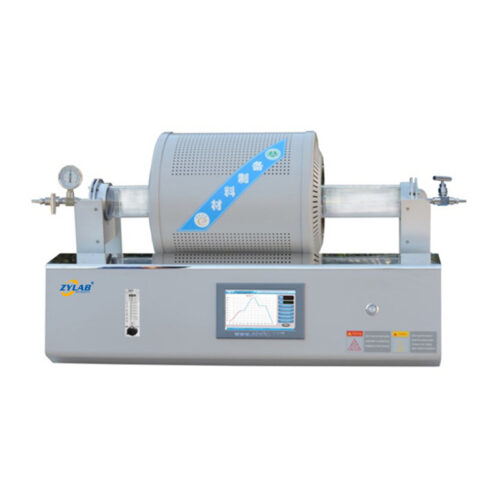

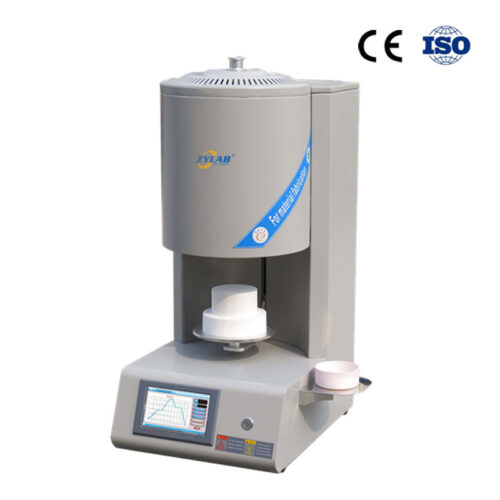

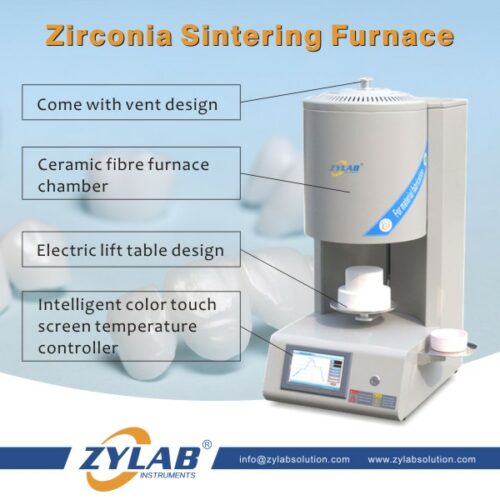

Large-Capacity Bottom-Loading Furnace with Precision Temperature Control for Sintering Applications

Introduction

The large-capacity bottom-loading furnace features a chamber lined with lightweight alumina refractory insulation material, offering excellent thermal insulation performance. The load-bearing platform is equipped with a screw lift system, facilitating the loading of large-sized materials. This equipment is widely used in universities, research institutes, and industrial enterprises for heat treatment experiments and production in fields such as powder metallurgy, ceramic materials, and military materials.

Key Features

- Uniform Material Sintering: Optional anti-corrosion protective lining for equipment operating below 1200°C to prevent material vapor corrosion to the furnace chamber.

- Silent Screw Lift Platform Design: Ensures lifting stability, prevents tilting of materials, and makes loading simple and efficient.

- Advanced Automation Control: Guarantees system stability and ease of operation.

- Touch Screen Operation: Intuitive temperature curve display for simplified and user-friendly operation.

Technical Specifications of Large-Capacity Bottom-Loading Furnace

| Model | B1500-16 | B1700-16 | B1200-38 |

| Electrical Specifications | AC220V 4KW | AC220V 4.5KW | AC380V 4KW |

| Maximum Temperature | 1500℃ (<1 hour) | 1700℃ (<1 hour) | 1200℃ (<1 hour) |

| Continuous Operating Temperature | 1450℃ (continuous) | 1650℃ (continuous) | 1150℃ (continuous) |

| Heating Rate | ≤20℃/min | ||

| Chamber Size | Φ160*200mm | Φ160*200mm | Φ380*220mm |

| Control System

(Intelligent Touch Screen Controller) |

1. PID automatic control and auto-tune function. 2. 30 programmable segments for precise control. 3. Built in protection for over-heated and broken thermal couple, and leakage. 4. Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. 5. Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes.

|

||

| Temperature Accuracy | ±1℃ | ||

| Heating Elements | Special high-density and high-purity silicon carbide rods

|

High-purity molybdenum disilicide rods

|

Molybdenum-doped Fe-Cr-Al alloy resistance wires

|

| Net Weight | 85KG | 115KG | 300KG |

| Service Support | One-year warranty with lifetime support (warranty excludes consumable parts such as heating elements and thermocouple). | ||

Applications

Bottom loading furnaces are widely used in various industries for their ease of loading and unloading from the bottom. Here are some key applications:

- Material Science: For sintering, annealing, and other thermal treatments of materials.

- Metallurgy: Used in metal processing and heat treatment.

- Chemical Engineering: For reactions, calcination, and other high-temperature processes.

- Ceramics: Suitable for firing and sintering ceramic materials.

- Laboratory Research: Applied in scientific studies and experiments requiring controlled high-temperature environments.

For More Content

Please read our blog: How to Select the Right Bottom-Loading Sintering Furnace for Large Workpieces?

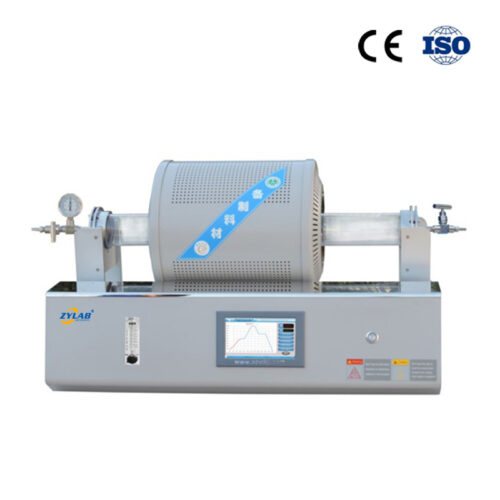

For More Options on Bottom Loading Furnaces

Please visit our website [Bottom Loading Furnaces Collection]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]