High-efficiency 50- 500g/h Lab Scale Jet Mill with Cyclone Separator and Collection Vessel

Introduction

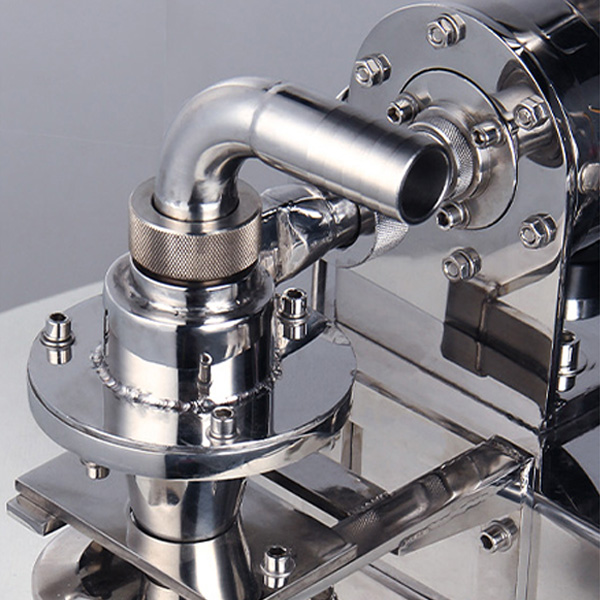

The lab scale Jet Mill is a tabletop micro unit specifically designed for laboratory use, suitable for experiments or the pulverization of ultra-small quantities of high-value materials. The overall design is exquisite, including vibrating feeding, control instruments, and valves, etc. It is extremely easy to clean and disassemble, facilitating frequent changes of research materials by researchers.

The jet mill utilizes high-speed compressed air or inert gas to propel materials, causing impact and shearing, which achieves material pulverization. The equipment operates stably and reliably, with a built-in vibrating feeder that allows for easy adjustment of the feeding speed. It is equipped with a cyclone separator and collection vessel for convenient product collection.

Applications

The lab scale jet mill is widely used in the fields of advanced ceramic materials, lithium battery cathode and anode materials, fine chemical materials, fine non-mineral materials, food and pharmaceutical raw materials, pigment and coating powders, etc.

Typical materials include: ultra-hard materials like diamond, silicon carbide, and metal powders; high-purity requirements such as ceramic pigments, pharmaceuticals, and biochemicals; low-temperature requirements such as pharmaceuticals and PVC.

Features and Benefits

- The main housing is made of 304 stainless steel, with an inner lining of high purity fully sintered alumina ceramic (corundum ceramic), ensuring wear resistance and no contamination.

- No rotating parts, ensuring stable and reliable operation.

- Built-in vibrating feeder for easy adjustment of feeding speed.

- Equipped with a cyclone separator and collection vessel for convenient product collection, with three dust-proof collecting bags included.

- Air consumption is 0.4~0.6 m³/min, with a working pressure of 0.6Mpa~1.0Mpa.

- The air supply system is to be provided by the user, connecting to the main air pipe, with the internal pressure regulator fully matched.

Technial Parameters

| Name | Lab Scale Jet Mill

(Ceramic Contamination-free Flat Jet Mil) |

Output Size | D50≤0.5~20um

(Depending on the material) |

| Model | JM-50 | Capacity | 50g~500g/h(0.05~0.5kg/h) |

| Feeding Size | ≤80 mesh

(recommend 80-300 mesh) |

Working Power | 30w

(vibrating feeder) |

| Dimensions | 500X300X450(mm) | Net Weight | 20kgs |

Note:

- The output particle size is depended on material hardness and input particle size. Coarse particles may need 3-5 times milling to obtain the finest size.

- An air compressor is required, standard is NOT included. (Please order one from a local store, recommendation for a screw-type air compressor to ensure stable air pressure and adequate airflow rate for normal laboratory requirements 0.6m³/min)

For More Information on Jet Mill

Please read our blog [Laboratory Jet Mill]

Watch Product Video

Click here to watch the demonstration video.

For More Sample Preparation Solutions

Please visit our website [Sample Preparation Collection]