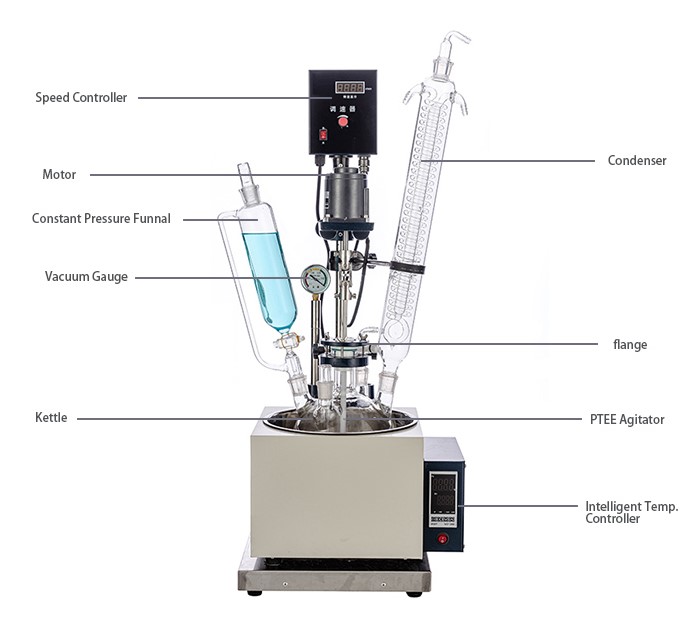

3L Lab Glass Reactor

Introduction:

This series lab glass reactor is our new single-layer glass reactor, produced on the basis of practical demands and standards of customers, absorbing advanced experience, technologies and advantages of similar products, and innovating boldly; it is not only convenient (one person can move, operate, wash, install and disassemble), but also novel and practical in structure, and it has elegant appearance, being in the lead in nation. In addition, it has become the ideal instrument in experiments and manufacturing of modern chemistry, fine chemical engineering, bio-pharmaceuticals and new material synthesis.

Lab Glass Reactor operating principle: put reaction materials into single-layer glass reactor, and vacuumize to stirring reaction simultaneously; add water or oil into outside water or oil bath to proceed heating reaction; control evaporation and back-flow of reaction solution, and charging under constant voltage . (optional refrigeration modules matched with refrigeration sources to proceed low-temperature reaction).

Features and Benefits:

1. Lab glass geactor body adopts high-borosilicate glass 3.3(GG-17 materials), which has superior physical and chemical performance, and transparent glass is convenient for user to observe reaction materials.

2. The shell of heating kettle is sprayed plastics to prevent corrosion, liner adopts superior stainless steel and is durable in use.

3.Rod and other accessories adopt stainless steel and aluminium alloy, elegant and secure.

4. Stainless stirring rod is coated PTFE, applied in multiple solvents stirring, which has no pollution and corrosive resistance.

5. Speed reducing and power increasing motor is stirring, and it has characteristics of running smoothly, large force moment, no-spark and long life.

6. PTFE modules and mechanical seal ensures favorable vacuum degree and long life.

7. Constant temperature oil(water) bath controls temperature intelligently, and displays oil or water temperature in bath; temperature control is realized by K sensor which is accurate. When water temperature reached pre-setting temperature, controller will cut heating source automatically; when it is lower, controller will connect heating source automatically so that water temperature is constant in tank.

8.The vacuum pressure gauge displays real-time vacuum and the pointer displays.

9.The mixing and heating double fuse has high safety protection performance.

Technical Parameters:

| Model | ZYLAB – F-3L | |

| Flask capacity | 3L, spherical | |

| Power supply | 220~240V/50Hz | |

| Mixing motor power | 90W | |

| Heating power | 2KW | |

| Stirring speed | 0-800rpm/min | |

| Temp of flask range | -80~ + 250.C | |

| Temp range of bath | Rt-180.C | |

| Temp accuracy | +/-1.C | |

| Achievable vacuum | 0.098Mpa | |

| Flask

Ф131mm, 5 necks |

Mixing | Ф50mm Flange port |

| Condenser | 29# standard port | |

| Funnel | 29# standard port | |

| Pressure relief | 24# standard port | |

| Temperature measuring | 24# standard port | |

| Agitator paddle | Ф10*500H(mm), paddle 90mm | |

| Condenser | Ф60*450H(mm), the upper 24#standard port,the lower 29#standard plug | |

| Constant pressure funnel | 500ml, the upper 24 # standard port is equipped with a glass plug, and the lower 29 # standard plug | |

| Pressure-relief system | 24 # plug valve, vent nozzle (pagoda joint) OD 10mm | |

| Temperature measuring | 24 # plug glass temperature measuring tube | |

| Receiving system | 2 adapters, 24 # standard port, 500 spherical collecting bottle | |

| Vacuum nozzle | 24 # glass air extraction head, nozzle (pagoda joint), OD 10mm | |

| Condensate coil inlet and outlet circulation nozzle | Pagoda joint, OD 10mm | |

| Bath size(mm) | Ф265*160H | |

| Dimension of overall (mm)W*D*H | (430-1030)*330*1100 | |

| Net weight (kgs) | 23 | |

| Package (mm) | 1020*480*520, wooden box,0.26m³ | |

| Gross weight (kgs) | 38 | |

Which kinds of industry can use this Lab Glass Reactor?

Modern chemistry, fine chemical engineering, bio-pharmaceuticals, new material synthesis, scientific research, environmental science, education, etc.

Applications of Lab Glass Reactor:

Laboratory glass reactors are versatile tools used in various scientific fields for a wide range of applications(such as chemical synthesis, drying, stirring, dissolving, mixing, etc.) due to their ability to control reaction conditions precisely and safely. Here are some common applications of lab glass reactors:

Chemical Synthesis

Glass reactors are widely used for chemical synthesis, enabling researchers to carry out reactions under controlled conditions such as temperature, pressure, and mixing. They are employed in organic synthesis, pharmaceuticals, polymerization, and more.

Process Development

Researchers use glass reactors to develop and optimize chemical processes before scaling up to industrial production. By running reactions in small-scale glass reactors, they can fine-tune parameters and identify potential challenges before moving to larger-scale setups.

Biotechnology and Biochemistry

Glass reactors are utilized in biotechnology and biochemistry research for various applications including enzyme kinetics studies, fermentation, protein purification, and cell culture. They provide a controlled environment for biological reactions and processes.

Material Synthesis

Glass reactors are employed in material science for synthesizing nanoparticles, nanocomposites, and other advanced materials. Precise control over reaction conditions allows researchers to manipulate the properties of materials at the molecular level.

Catalysis Studies

Glass reactors are used to investigate catalytic reactions and study the performance of catalysts under different conditions. Researchers can evaluate the effectiveness of catalysts in promoting specific reactions and optimize their design.

Extraction and Purification

Glass reactors are utilized for extraction and purification processes in chemistry and biochemistry, such as solvent extraction, distillation, and chromatography. They provide a controlled environment for separating and purifying compounds from complex mixtures.

Pharmaceutical Research and Development

Glass reactors play a crucial role in pharmaceutical R&D for drug synthesis, formulation, and process optimization. Researchers use them to develop new drug compounds, study reaction kinetics, and ensure product quality and consistency.

Environmental Analysis

Glass reactors are employed in environmental research for analyzing pollutants, studying degradation processes, and developing remediation techniques. They enable researchers to simulate environmental conditions and investigate the fate of contaminants.

Education and Training

Glass reactors are used in academic settings for teaching chemistry, chemical engineering, and related disciplines. Students learn basic principles of chemical reactions, process control, and safety practices by conducting experiments in laboratory glass reactors.

Quality Control

Glass reactors are utilized in quality control laboratories for batch testing, product validation, and process monitoring in industries such as pharmaceuticals, food and beverage, and chemicals. They help ensure that products meet regulatory standards and specifications.

Overall, lab glass reactors are indispensable tools in scientific research, providing a controlled environment for conducting a wide range of chemical and biological experiments and processes.