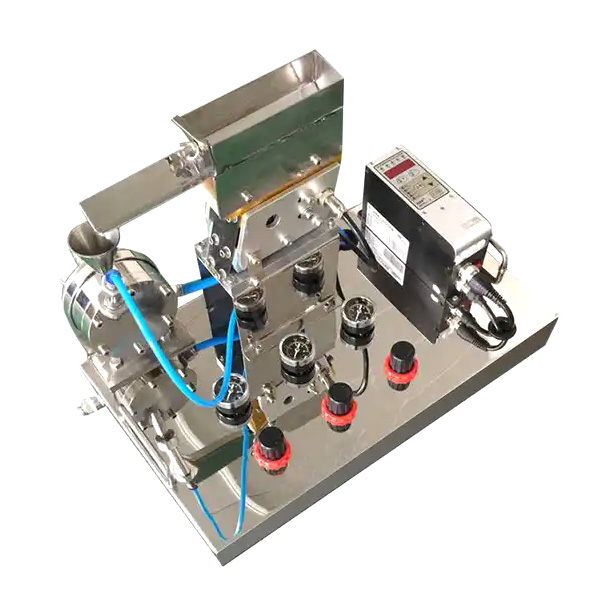

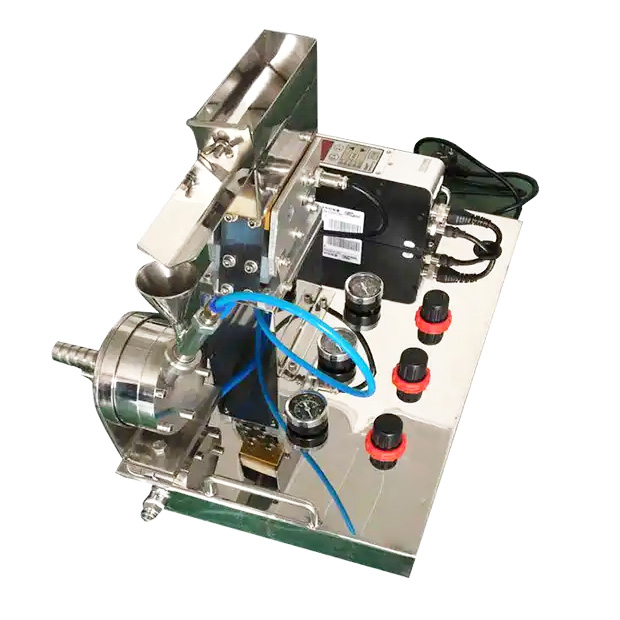

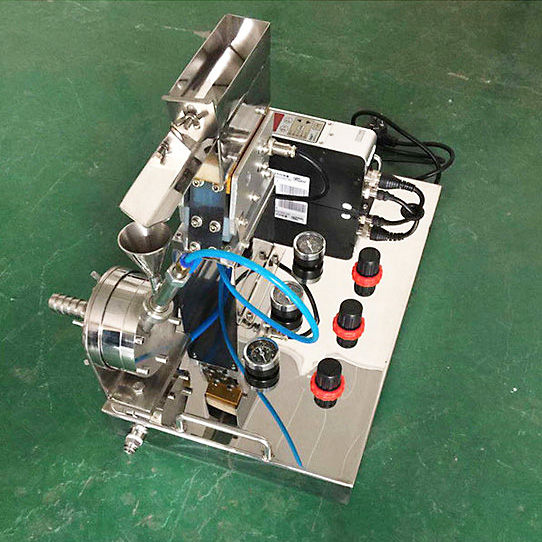

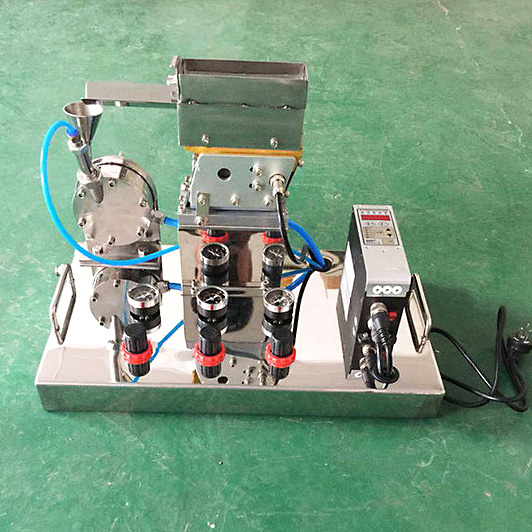

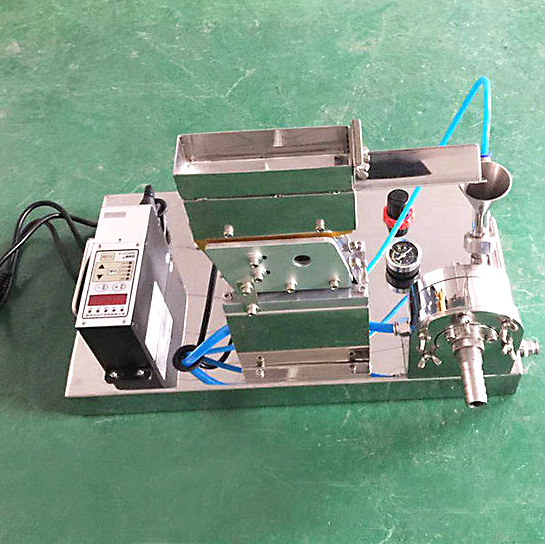

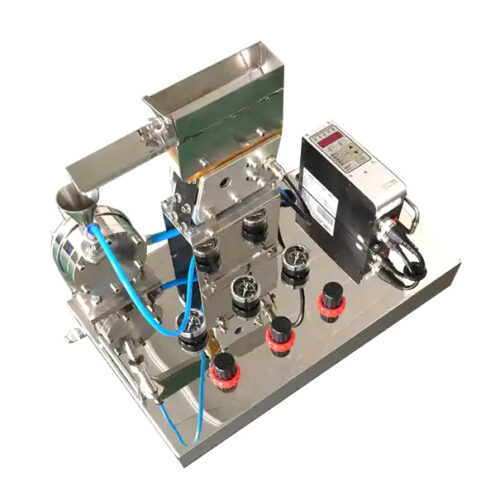

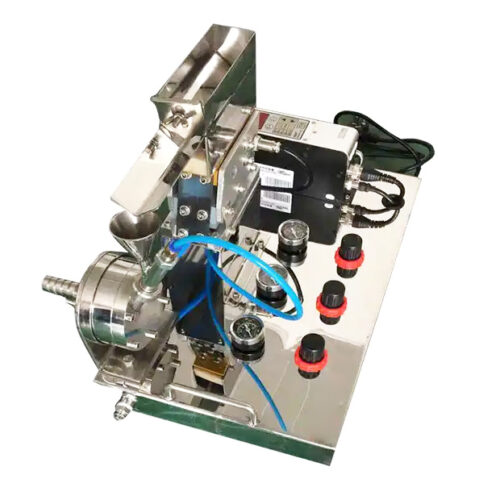

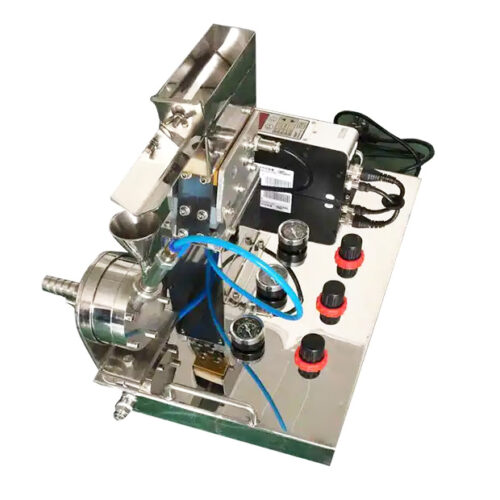

Laboratory Compact Jet Mill 5 – 500 g/hr

Introduction:

Laboratory compact jet mill is a kind of ultra-small bench-top machine, which is is suitable for superfine pulverization of ultra-small material with high value in laboratory.

Characteristics of Compact Jet Mill:

1. Tabletop Mini Machine: This is an ultra-compact machine that can be placed on a workbench and is suitable for ultra-fine grinding of small quantities of high-value powders in laboratory settings.

2. High Recovery Rate: With a quick blow of compressed air, the machine interior becomes clean, making it especially suitable for laboratories where powder varieties are frequently changed.

3. Wide Application: Used for crushing high-hardness, brittle materials, such as zirconia sand, zirconium oxide, silica, alumina, calcium carbonate, carbon black, AC foaming agent, coatings, fluorescent powders, various fillers for plastics and rubber, pearl powders, etc.

Technical Details:

Model: JM-1

Processing Capacity: 5-500g/hr

Feed Size 100-200 mesh, Output Size 2-5 micrometers (The output particle size is depended on material hardness and input particle size. Coarse particles may need 3-5 times milling to obtain the finest size.)

Air Consumption: >0.4M3/min

Pressure: Feeding Nozzle 0.3~0.4MPa; Grinding Pressure 0.6~0.7MPa(An air compressor is required, standard is NOT included. (Please order one from a local store,recommendation for a screw-type air compressor to ensure stable air pressure and adequate airflow rate for normal laboratory requirements-0.6m³/min))

Power Requirement: 5.5KW/hr

Dimensions: 540X340X250(mm)

Net Weight: 15kg

Application Fields:

Laboratory compact jet mill can be especially suitable for laboratories which need to change different materials frequently. This machine is often applied to pulverize various kinds of high hardness and brittle materials like zircon sand, zirconia, silica, alumina, calcium carbonate, carbon black, AC blowing agent, coating, fluorescent powder, plastics, pearl powder, various fillers for rubber, and etc.

Working Principle:

Powder material is sent to the feeding nozzle by the electromagnetic vibration feeder, and is injected into the pulverizing cavity by action of the feeding compressed air. The materials entering the pulverizing chamber and the high-speed air flow ejected by the pulverizing nozzle form a supersonic flow group, so that the materials collide and shear with each other in the pulverizing chamber and collide and rub with the wall of the pulverizing chamber, and finally achieve the purpose of pulverizing the materials into micron fine powder. In process of high-speed movement and material pulverizing, the particles with different fineness will produce different centrifugal forces in the rotating air flow. The powder particles with qualified fineness will be taken to the discharge pipe by exhaust flow because its centripetal air flow force is greater than centrifugal force, and then the finished powder will be collected by the cloth bag; The larger particles are thrown to the surroundings because its centrifugal force is greater than force of centripetal air flow, and are continuously crushed by continuous high-speed movement of the flow group.