2~4L PLC Intelligent Planetary Ball Mill

Introduction:

This intelligent planetary ball mill is a necessary device for mixing, fine grinding, small samples prepared, dispersion of nanomaterial, R&D of new materials and small batch production for high tech materials.

Widely used in R&D institute, collages and universities, enterprise laboratory(Four samples can be obtained at the same time in each experiment). The samples could be ground under vacuum state with using the vacuum ball mill jars.

Application Fields:

Pearl, ginseng, Dendrobium officinale, tablet, pharmaceutical, pharmaceutical, licorice, coke, coal, glass, cellulose, paper, chip, polymer, pigment, metal oxide, iron ore, iron powder, aluminum powder, magnesium powder, ceramics, alumina, bone, kaolin, limestone, gypsum, quartz, mineral, ore, carbide fiber, graphite, ink, clay minerals, fiber products, sewer sludge, catalyst, chemicals, alloy, soil, waste samples, wood, plant ingredients, cement slag, concrete, slag, tobacco.

Features and Benefits:

1.Small volume, structure using thickened steel plate, shell using thickened plate, vibration resistance, smooth, sound insulation, safety, internal and external spray-paint treatment;

2.Adopt patent technology of oil seal and noise-reducing material to reduce noise and improve comfort.

3.Automatic processing, no need to debug, simple to use, practical and comprehensive function

4.Low power, low loss, low cost, low fault

5.European standard conical drive wheel, European standard electrical parts and circuit design, brand inverter, electric and other high standard accessories to ensure quality and service life;

6.The impact energy is strong, the discharge is more uniform, the precision is higher, the crushing ability is stronger, the granularity of the sample is finer and the processing speed is faster.

7.Can set grinding time, intermittent time, movement direction, movement speed, and has power loss memory, emergency stop, overload protection function

8.Samples can be dry and wet grinding, and can be equipped with vacuum ball mill tank for vacuum grinding, pressurized mill, inert gas grinding

9.Reconfigurable liquid nitrogen cryogenic system for ultra-low temperature treatment (Optional)

10.It can realize the detection of temperature and pressure in the ball mill carrier (Optional).

Technical Details:

| Name | PLC Intelligent Planetary Ball Mill | |

| Model | ZM-2L(Oil seal mute) | ZM-4L(Oil seal mute) |

| Jar size/capacity | 25/50/100/250/500ml | 25/50/100/250/500/1000ml |

| Vacuum jar size | 50/100/250ml (only stainless steel jar) | 50/100/250ml/500ml(only stainless steel jar) |

| Feed Material Capacity | 16ml-160ml | 16ml-330ml |

| How to use small jar | 50/100/250ml with a bottom tray | 50/100/250/500ml with a bottom tray |

| Intelligent time set | 5 grinding time selections | |

| Feed material capacity | 1/3 capacity of ball mill jar | |

| Feed Material | Medium or low hardness, hard, brittle, fibrous, viscous. | |

| Size Reduction Principle | Impact Force, Shear Force, Friction Force, Crushing, grinding, mixing, homogenization, alloying | |

| Main Disk Structure | Planetary main disk gear invades and reinforces in lubricating oil, noise isolation treatment | |

| Standard | CE | |

| Electrical Description | 100-120V/200-240V AC ,50-60Hz, 1PH (0.75KW) | |

| Material Feed Size | < 5 mm soil<10 mm | |

| Final Fineness | < 100 nm | |

| Batch Size / Feed Quantity | 4 x 500 ml/4 x 1000 ml | |

| Sun Wheel Speed | 10 – 400 r/min | |

| Ball Mill Jar Speed | 20 – 800 r/min | |

| Total Grinding Speed | 1200 /min | |

| Speed Ratio | 1:02 | |

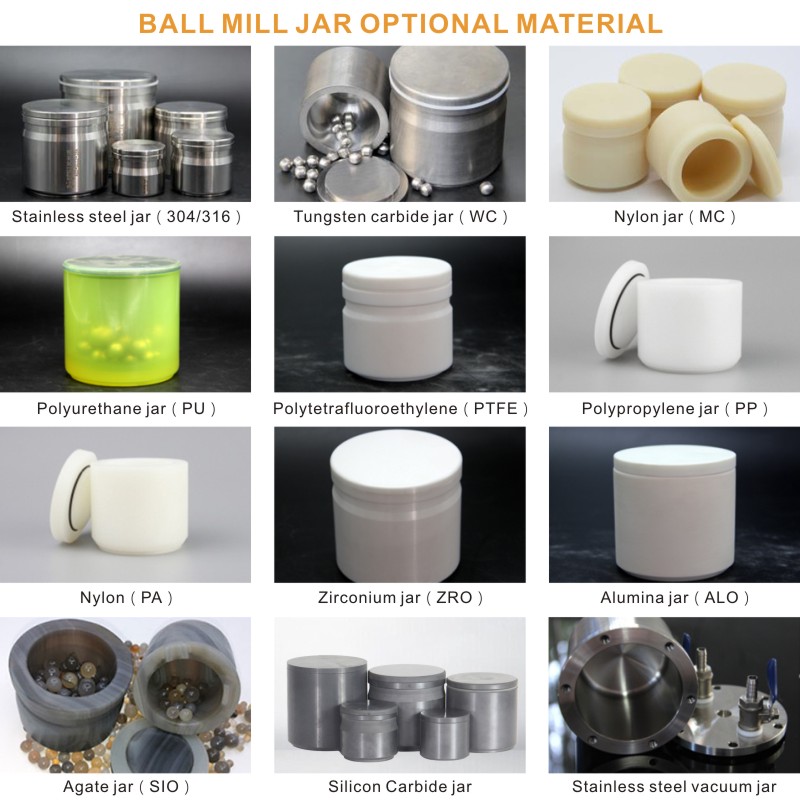

| Material of Grinding Tools | Stainless steel, agate, zirconia, corundum/alumina, tungsten carbide, nylon, polyurethane, polytetrafluoroethylene, silicon carbide, etc. | |

| Ball Size | 1 / 2 / 3 / 5 / 8 / 10 / 15 / 20 / 25 / 30 mm | |

| No. of Grinding Stations | 2 or 4 | |

| Mode | Vertical planetary | |

| Grinding Mode | Dry/wet | |

| Low Temperature Cooling Treatment | Yes (air cooler added) | |

| Oil Seal Position | The bottom of planetary main disk | |

| Disk Dimensions | 360 mm | |

| Oil Seal Capacity | 800ml(fill in before using the planetary ball mill) | |

| Noise | < 60dB(Within 3 metre) | |

| Protection Code | IP60 | |

| W x H x D Closed | 780 x 580 x 680 mm | |

| Net Weight | 98/100 kg | |

Matched Ball Mill Jars:

Detail Applications of Intelligent Planetary Ball Mill:

Intelligent planetary ball mills are powerful tools used to grind, blend, and mix materials in various scientific and industrial applications. Their versatility and efficiency make them valuable tools for a wide range of processes. Some of the key applications of planetary ball mills include:

Nanomaterial Synthesis:

Planetary ball mills are commonly used for the synthesis of various nanomaterials, including nanoparticles, nanocomposites, and nanostructured materials. The high-energy collisions and milling action in the ball mill facilitate the mechanical alloying and grinding down to the nanometer scale.

Mechanical Alloying:

This process involves the repeated welding, fracturing, and rewelding of powder particles to create alloyed materials with improved properties. Planetary ball mills are ideal for performing mechanical alloying due to their ability to achieve high-energy impacts.

Powder Metallurgy:

Planetary ball mills are utilized in powder metallurgy processes for manufacturing metal powders and producing homogeneous blending of metal and non-metal powders.

Material Testing:

These mills can be used to test and evaluate the mechanical properties of materials. By subjecting materials to high-energy impacts and grinding, researchers can study their behavior under different conditions.

Pharmaceuticals and Drug Development:

Planetary ball mills can be employed in pharmaceutical research to grind, blend, and homogenize active pharmaceutical ingredients (APIs) and excipients for drug formulation.

Ceramics and Glass Industries:

In the ceramics and glass manufacturing sectors, planetary ball mills are used to grind raw materials, enhance mixing, and create uniform suspensions for subsequent shaping and firing processes.

Paints and Coatings:

For the production of paints, coatings, and inks, planetary ball mills can disperse and blend pigments with other components to achieve consistent color and texture.

Battery Materials:

Planetary ball mills are employed in the production of battery materials, such as electrode materials and electrolytes, through mechanical blending and synthesis.

Geology and Mining:

These mills can be used in geology and mining applications to grind rocks, ores, and minerals for sample preparation or mineral liberation.

Catalysis and Chemical Engineering:

Planetary ball mills are used in chemical synthesis and catalytic processes to facilitate mixing, blending, and mechanochemical reactions.

Food and Beverage Industry:

In the food industry, planetary ball mills can be employed for mixing, grinding, and homogenizing ingredients to create products like sauces, pastes, and creams.

Environmental Applications:

Planetary ball mills can be used for the destruction of hazardous waste materials or for wastewater treatment processes.

The above applications demonstrate the versatility of planetary ball mills across various industries and research fields. Their ability to achieve high-energy impacts and mechanical blending makes them indispensable tools for numerous material processing and synthesis tasks.