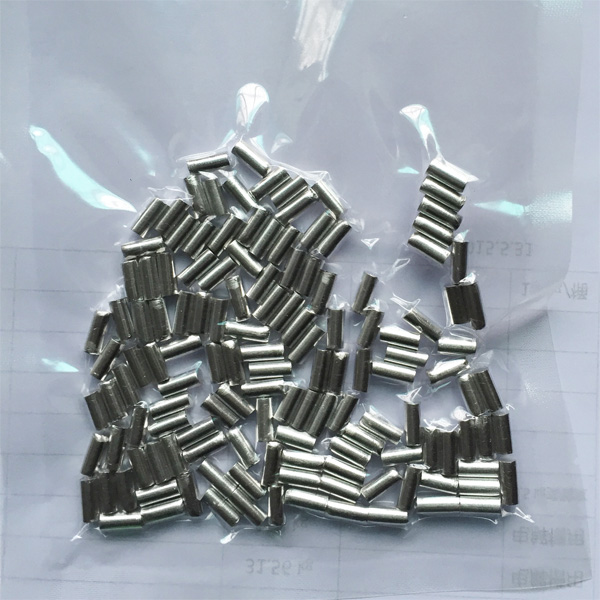

4N (99.99%) Indium (In) Pellets Evaporation Materials

Introduction:

Indium evaporation materials are solid substances primarily composed of indium, specifically engineered for use in thermal evaporation processes. These materials typically come in various forms such as pellets, rods, wires, or sheets, suitable for vaporization in vacuum environments.

During the thermal evaporation process, the solid indium material is heated to its vaporization temperature, causing it to transition directly from a solid to a vapor state. The vaporized indium then condenses onto a substrate surface, forming thin films or coatings with desired properties.

Indium evaporation materials find applications in various industries due to indium’s unique properties, such as high ductility, excellent thermal and electrical conductivity, and low melting point. They are commonly used in the production of semiconductors, solar cells, and transparent conductive coatings for displays and touchscreens.

Properties of Indium Evaporation Materials:

1. Softness and Ductility

Similar to Gallium: Indium shares properties similar to gallium, including softness and malleability. This characteristic enables indium to conform to and cling to glass and other surfaces, facilitating its use in various applications.

2. Low Melting Point

Melting Point: Indium exhibits a relatively low melting point of 157°C, making it suitable for low-temperature deposition processes.

Ease of Vaporization: The low melting point of indium allows for efficient vaporization at moderate temperatures, enabling the deposition of thin films or coatings on substrates.

3. Density and Vapor Pressure

Density: Indium possesses a density of 7.3 g/cc, contributing to its substantial mass and stability in various applications.

Vapor Pressure: At a vapor pressure of 10-4 Torr at 742°C, indium exhibits favorable vaporization characteristics conducive to thin film deposition processes.

4. Adhesion Properties

Surface Adhesion: Indium has a propensity to cling to glass and similar surfaces, making it suitable for applications requiring strong adhesion properties.

Compatibility with Substrates: The adhesion properties of indium enable uniform and durable coatings on various substrates, enhancing the performance and functionality of coated materials.

Applications:

1. Electronics

Indium evaporation materials find extensive use in the electronics industry for the deposition of thin films or coatings on electronic components and devices.

Indium-based coatings enhance the conductivity, corrosion resistance, and reliability of electrical contacts, solder joints, and interconnects in electronic circuits.

2. Photovoltaic Cells

In the field of photovoltaics, indium evaporation materials play a vital role in the production of thin-film solar cells and photovoltaic modules.

Indium-based thin films deposited on solar cell substrates enable efficient light absorption, charge carrier transport, and electrical output, contributing to the performance and efficiency of solar energy conversion devices.

3. Semiconductors

Indium evaporation materials are utilized in semiconductor manufacturing processes for the deposition of indium-based thin films and layers on semiconductor substrates.

Indium-based semiconductor materials exhibit desirable electrical, optical, and mechanical properties, making them suitable for a wide range of semiconductor applications, including transistors, diodes, and optoelectronic devices.

4. Transparent Conductive Coatings

Indium-based transparent conductive coatings find application in the production of displays, touchscreens, and electronic devices requiring transparent and conductive surfaces.

Indium evaporation materials enable the deposition of indium tin oxide (ITO) and other indium-based coatings with high transparency, conductivity, and durability, facilitating the operation and functionality of electronic displays and touch-sensitive interfaces.

Specification:

Our standard size is 1mm Diameter x 5mm Length, and other specifications are also available.Please consult our professional customer service personnel for detailed information.

Our standard packaging sizes include 10 grams, 20 grams, 50 grams, 100 grams, 500 grams, 1000 grams.

ZYLAB offers a variety of crucibles for evaporation materials.