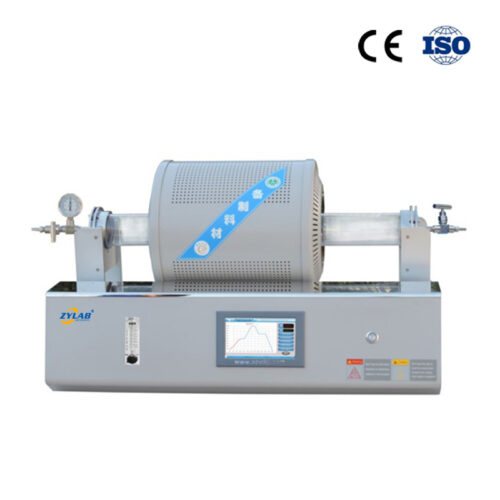

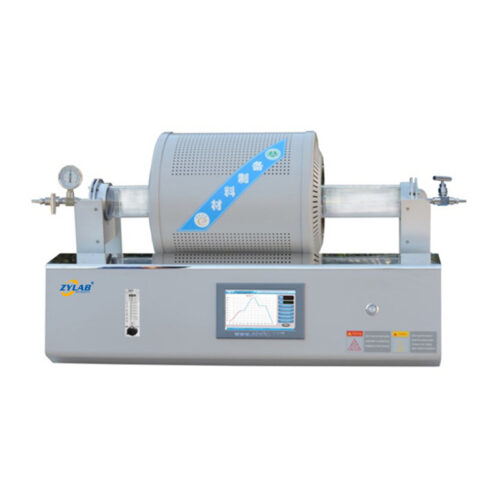

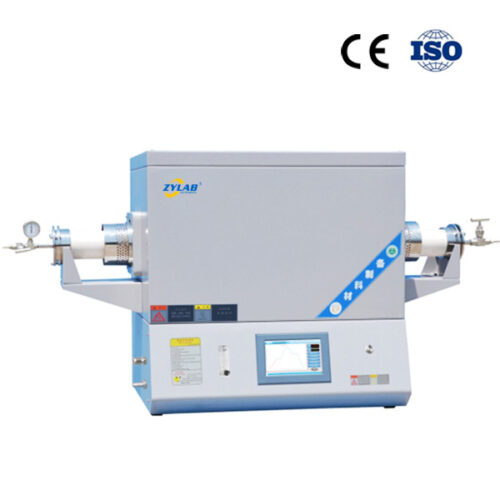

1200°C Hydrogen Reduction Sintering Furnace

Introduction:

The Hydrogen Reduction Sintering Furnace is a specialized equipment developed for higher education institutions, research institutes, and industrial enterprises. It is designed for sintering, melting, and analyzing metals, non-metals, and other compound materials under atmospheric and vacuum conditions.

The Hydrogen Reduction Sintering Furnace consists of the following components:

Sintering System

Electrical Control System

Inlet and Outlet Gas Systems

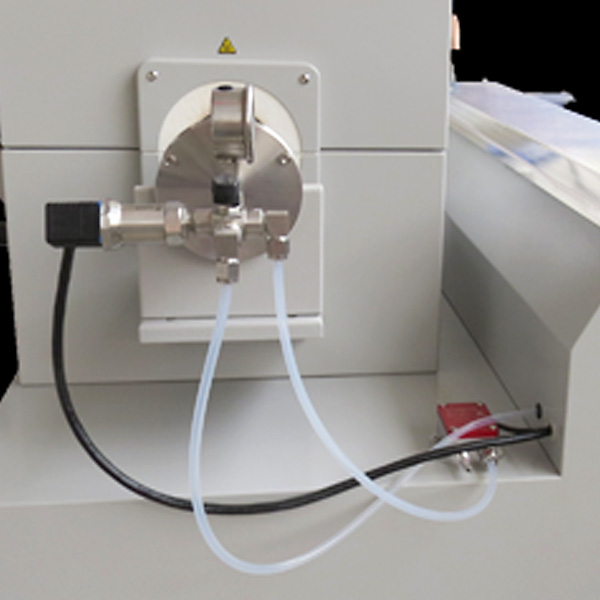

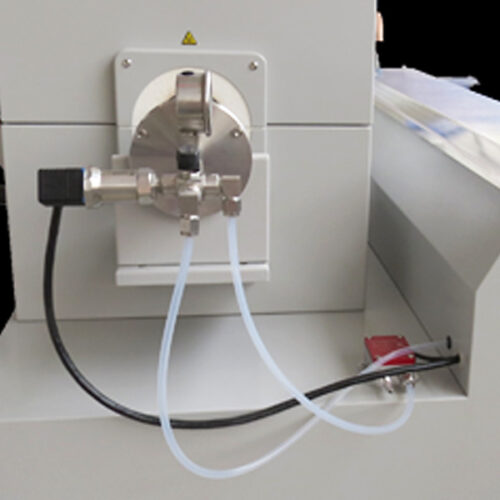

Vacuum System

Ignition System

Features:

1.Suitable for both low vacuum and atmosphere sintering.

2.Stable and reliable control, user-friendly operation, and comprehensive safety measures.

3.Utilizes advanced PID self-learning fuzzy control for high temperature control precision, maintaining accuracy within ±1℃.

4.Furnace lining made of high-purity alumina lightweight fiber material for enhanced insulation and energy efficiency.

5.Data storage function capable of retaining crucial sintering parameters for up to 30 days (8 hours of operation per day).

6.Formula storage feature with the ability to save more than 100 preset formulas.

7.Unique ignition device ensures complete hydrogen combustion and prevents external air from entering the furnace tube, significantly improving the safety of hydrogen usage.

Technical Parameters:

| Model | O1200-80TID3FW-150 |

| Power supply | 220V 50HZ, 5.5kw |

| Thermocouple | K type 420mm |

| Max.temp | 1150℃ |

| Heating size | Φ150*400mm |

| Heating rate | 10℃/min |

| Float flowmeter range | 0.1-0.8L/min |

| Furnace tube | High purity quartz tube, capacity 4L |

| Vacuum pump | 4C KF25 |

| Intelligent control system | 1.Intuitive 7-inch touchscreen.

2.Enhanced safety with pressure protection control. 3.Easy configuration of sintering process curves. 4.Convenient scheduled sintering for unattended operation based on preset curves. |

| Temperature accuracy | ±1℃ |

| Weight | About 210KG |

| Warranty | One-year, with lifelong support (consumables such as furnace tubes and O-rings are not covered within the warranty scope). |

Applications:

The Hydrogen Reduction Sintering Furnace has diverse applications across several industries due to its unique capabilities. Here are some specific applications:

1. Powder Metallurgy:

• Sintering metal powders with hydrogen reduction to enhance density and mechanical properties.

• Production of precision components for automotive, aerospace, and tooling industries.

2. Ceramic Manufacturing:

• Hydrogen reduction sintering for advanced ceramics, improving strength and durability.

• Production of specialized ceramic components for electronic devices and industrial applications.

3. Additive Manufacturing (3D Printing):

• Post-processing of 3D printed metal parts through hydrogen reduction for improved mechanical characteristics.

• Enhancing the properties of additively manufactured components.

4. Electronics and Electrical Components:

• Sintering of electronic components, such as contacts, connectors, and resistors.

• Manufacturing components with improved conductivity for electronic devices.

5. Battery and Energy Storage:

• Production of electrodes and other components for batteries using hydrogen reduction processes.

• Manufacturing materials for hydrogen-based energy storage technologies.

6. Advanced Material Research:

• Experimentation with hydrogen reduction sintering for the development of novel materials.

• Investigating the impact of hydrogen reduction on the properties of various materials.

7. Catalyst Production:

• Sintering of catalytic materials with hydrogen reduction for use in chemical processes.

• Manufacturing catalysts for industrial applications, such as petrochemical refining.

8. Medical Device Manufacturing:

• Sintering of metal and ceramic components for medical devices.

• Production of implants and other biomedical components with precise specifications.

9. Aerospace and Defense:

• Manufacturing specialized components for aerospace and defense applications using hydrogen reduction sintering.

• Producing lightweight and high-strength materials for aerospace structures.

10. Research and Educational Institutions:

• Utilization of the furnace in materials science research and experiments.

• Training and education in materials engineering and related fields.

The Hydrogen Reduction Sintering Furnace’s ability to provide controlled hydrogen atmospheres allows for the production of materials with specific properties, making it applicable in a wide range of industries that require precision sintering processes.