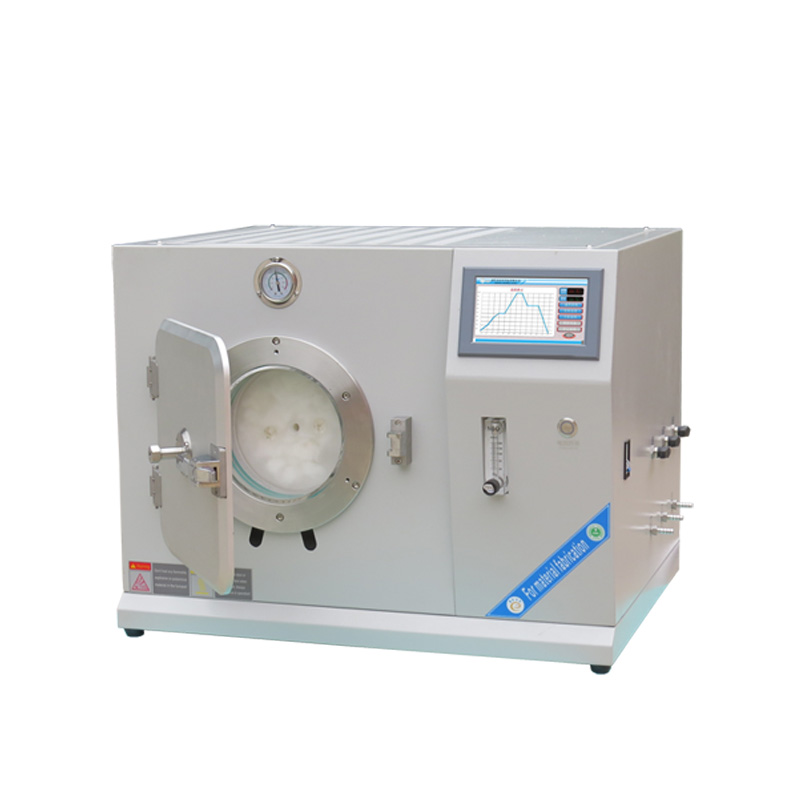

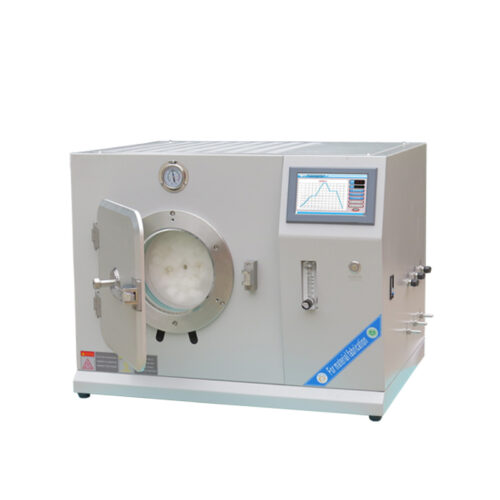

Large Caliber Hydrogen Reduction Furnace

Introduction

The Large Caliber Hydrogen Reduction Furnace is designed for sample preparation of various materials under a clean environment in a reducing atmosphere. The product utilizes a annular distributed heating uniformly positioned outside a high-purity quartz vacuum chamber, ensuring high thermal efficiency, rapid heating, and excellent temperature uniformity. The protective atmosphere circulates evenly inside, with ingress and egress for optimal performance. All sealing components feature high-temperature-resistant sealing rings, and the system employs a water-cooled stainless steel sealing system, ensuring safety and reliability.

The equipment is equipped with a comprehensive touchscreen interface for automated operation and includes alarm functions for over-temperature, disconnection, and low water pressure, enhancing user safety.

Key Features of Hydrogen Reduction Furnace

1.Double-layer insulation structure with air-cooled intermediate layer;

2. High-purity Al2O3 fiber refractory insulation material, maximizing energy savings;

3.High-purity alumina coating on the refractory furnace chamber for extended lifespan;

4.High-purity quartz furnace plug facilitates the establishment of custom temperature gradients within the tube.

5.Comprehensive over-temperature, short-circuit, and rapid cooling water protection measures for worry-free safety!

6.Temperature measurement holes and observation windows are interchangeable (selectable).

Technical Parameters

| Equipment Name | Large Caliber Hydrogen Reduction Furnace |

| Model | VAH1200 |

| Power Supply | 220V 50Hz |

| Rated Power | 3.5KW |

| Maximum Temperature (Tmax) | 1200℃ |

| Working Temperature | RT- 1150℃ |

| Recommended Heating Rate | ≤10℃/min |

| Heating Element | Annular heating Mo-doped Fe-Cr-Al high quality alloy heating element ensures uniform and reliable temperature distribution.

|

| Control System | 1. Sintering Process Curve Setting: Dynamic display of set curves. Multiple sintering process curves can be pre-stored, with each curve freely configurable. 2. Scheduled Sintering: Enables unattended operation by pre-setting the sintering process. 3. Real-time Data Monitoring & Recording: Displays and records sintering power, voltage, and other parameters. Supports data export for paperless recording. 4. Remote Operation: Allows real-time monitoring and remote control of the equipment. 5. Temperature Correction: Non-linear correction of the temperature difference between the main control temperature and the sample temperature throughout the sintering process.

|

| Temperature Control Accuracy | ±1℃ |

| Sensor Type | K-type Thermocouple Φ1×500mm |

| Effective Heating Zone of Quartz Vacuum Chamber | Φ190×220mm |

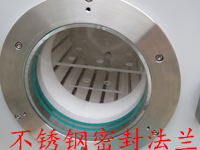

| Double-layer Quartz Plate Dimensions | 110×228×5mm, 187×228×5mm

Show as below(Perforated plate for a more uniform atmospheric environment):

Optional quartz holder:  |

| Sealing System | Stainless steel vacuum flange

Vacuum level:5-10Pa(Mechanical Pump) |

| Gas Supply System and

Pressure Measurement |

Utilizing a mechanical pressure gauge with shock-absorbing oil and a high-precision float flowmeter with a small flow rate. (can customized high-precision MFC) |

| Rotameter Flow Range | 20-200ml/min |

| Furnace Dimensions | L820×H1240×D640mm |

| Weight | Approx. 110kg |

| Precautions for Use | 1. Cooling System Requirement: When conducting high-temperature sintering, a water chiller must be connected to prevent the high-temperature silicone sealing ring from melting. 2. Material Compatibility Warning: Avoid sintering materials containing alkaline ions, as they may cause crystallization damage to the chamber. |

| Service Support | Two-year limited warranty with lifetime support (The warranty does not cover consumable parts such as the quartz chamber and O-rings). |

Applications

The Large Caliber Hydrogen Reduction Furnace has diverse applications across various industries and research fields due to its capabilities in providing a controlled and clean environment for sample preparation under a reducing atmosphere. Some notable applications include:

- Materials Science and Research:

- Synthesis and preparation of advanced materials under hydrogen reduction conditions.

- Investigation of material properties at high temperatures and in controlled atmospheres.

- Catalyst Development:

- Catalyst activation and preparation for chemical processes requiring a reducing atmosphere.

- Studies on catalytic reactions and their performance under specific temperature and gas conditions.

- Nanomaterial Synthesis:

- Production of nanoparticles and nanostructures in a controlled and reducing environment.

- Research on the influence of hydrogen reduction on the properties of nanomaterials.

- Metallurgy and Metal Processing:

- Heat treatment and processing of metallic samples under a hydrogen atmosphere.

- Investigation of the reduction behavior of metal oxides for metallurgical applications.

- Semiconductor Industry:

- Annealing and processing of semiconductor materials in a controlled and reducing atmosphere.

- Studies on the impact of hydrogen reduction on semiconductor device properties.

- Energy Storage Research:

- Development and testing of materials for energy storage applications, such as batteries and fuel cells.

- Evaluation of the performance of energy storage materials under reducing conditions.

- Advanced Ceramics Production:

- Reduction and sintering of ceramic materials to achieve specific properties.

- Investigation of the influence of hydrogen reduction on ceramic material characteristics.

- Research in Clean Energy Technologies:

- Studies on hydrogen-related technologies and their applications in clean energy production.

- Development of materials for hydrogen storage and fuel cell technologies.

The Large Caliber Hydrogen Reduction Furnace, with its high-temperature capabilities, controlled atmosphere, and safety features, is a valuable tool for researchers and industries involved in a wide range of scientific and technological pursuits.

For More Options on Hydrogen Reduction Furnace

Please click here [Hydrogen Reduction Furnaces Collection]

For More Options on High Temperature Furnaces

Please click here [High Temperature Furnaces Collection]

Read Our Blog for More Content

Key Equipment for Crystalline Hydrogen Reduction Processes

The Critical Role of Hydrogen Purge Reduction Furnaces in Semiconductor Material Synthesis

Advanced High-Temperature Furnaces for Hydrogen Furnace Steel Research