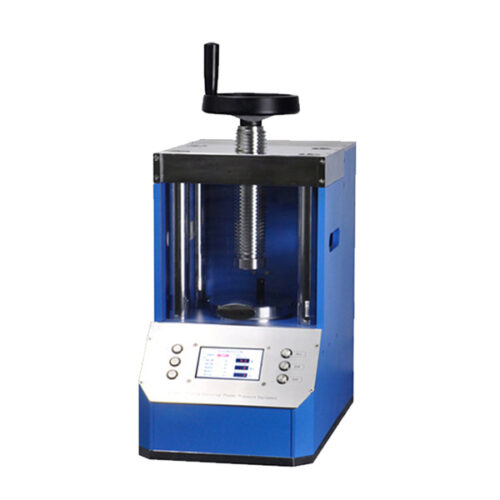

Laboratory Small Scale 3-Ton Manual Hydraulic Pellet Press

Introduction:

The Hydraulic Pellet Press is a device used to compress powder or granular materials into tablets or pills. It is commonly used in various industries, including pharmaceuticals, research, education, quality control, and materials development.

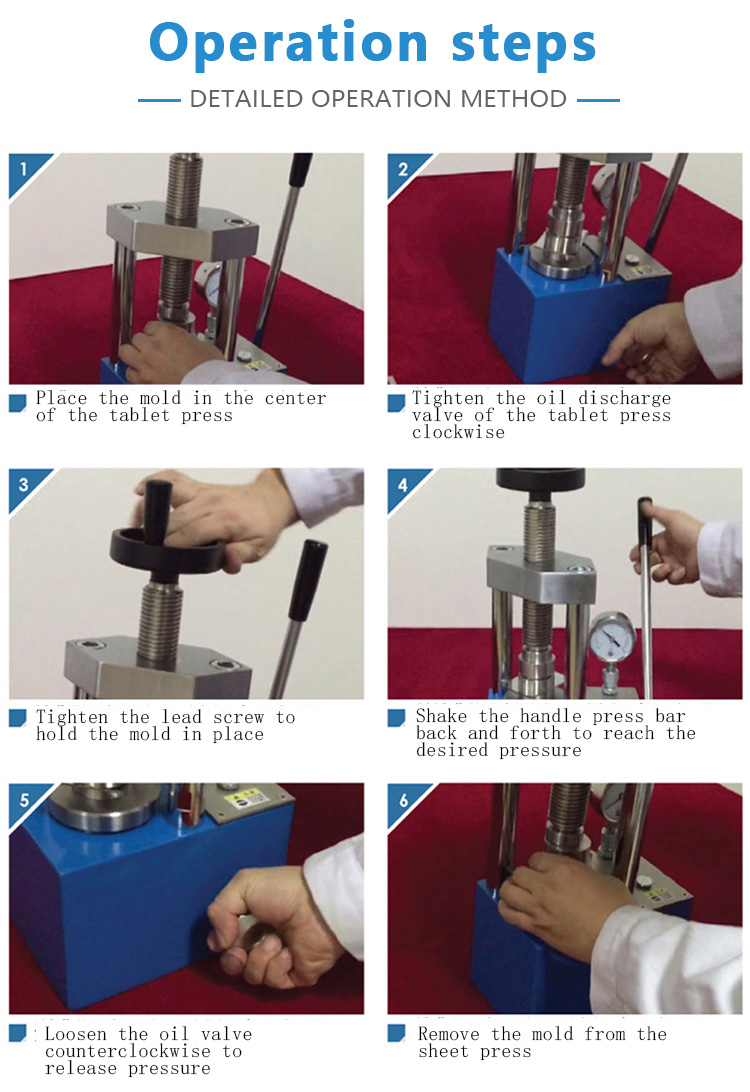

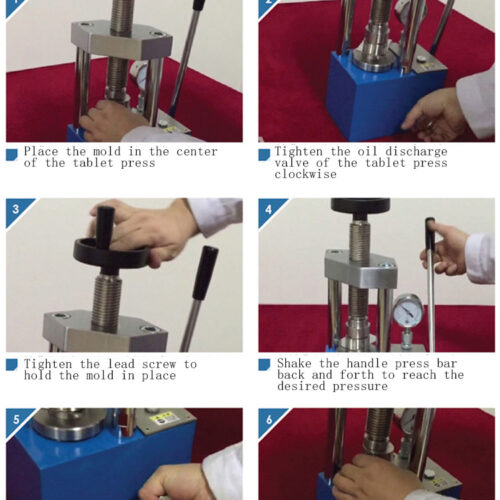

The process involves placing a specific quantity of the powdered or granular material into a die cavity, and then using the manual press to apply pressure to compact the material into a tablet. Manual tablet presses are often employed in small-scale or laboratory settings where the production volume is relatively low, and precision is crucial.

This press is versatile and can be equipped with different dies or molds to produce tablets of various shapes and sizes. It find application in the production of pharmaceutical tablets for research and development purposes, as well as in industries where small-scale tablet production or sample preparation is required.

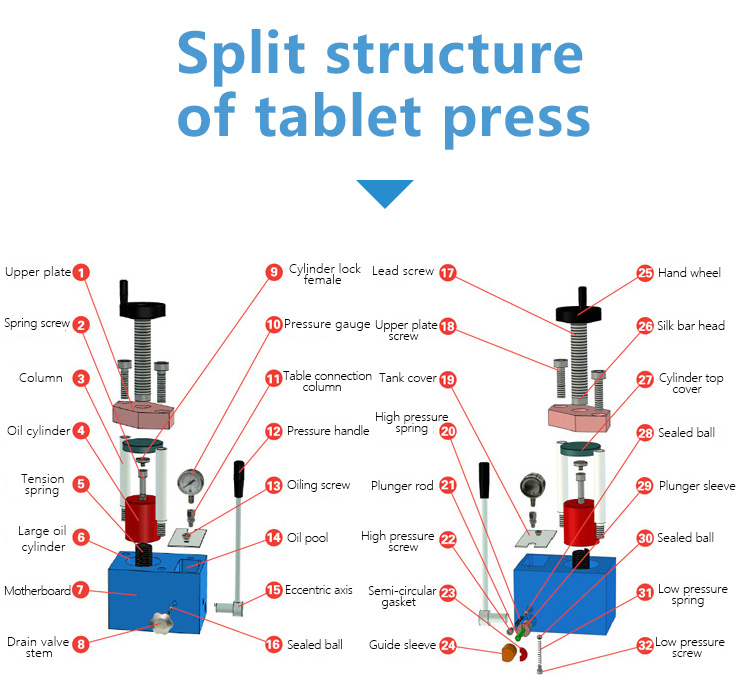

Detail Structure:

Features and Benefits:

1.Small size, light weight, no oil leakage, easy to carry.

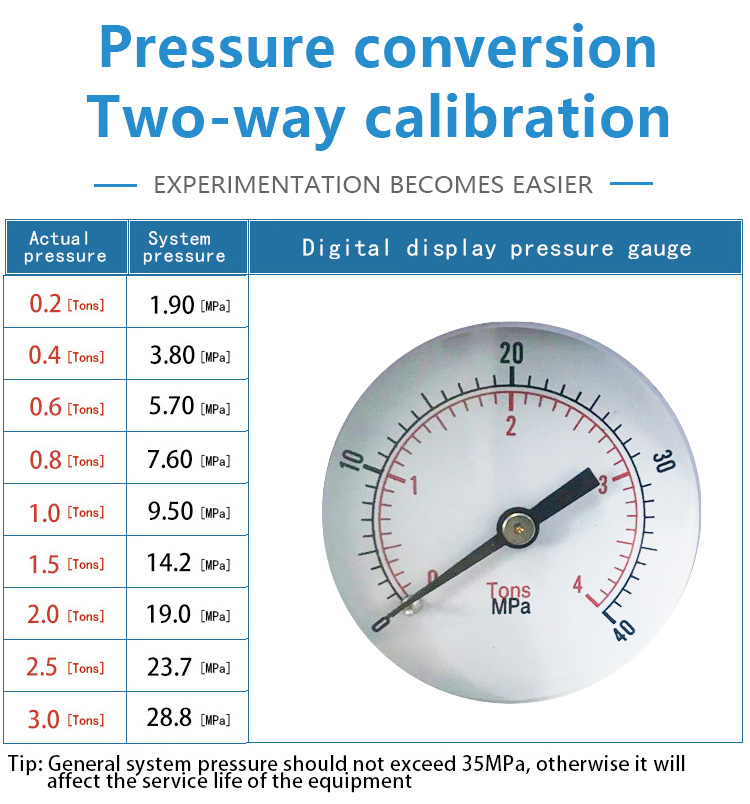

2. Digital display pressure gauge 0.1MPa,Pressure control is more accurate.

3.The oil pool is easy to replace oil on the main surface of the host, and the hydraulic oil filter is added to the oil path.

4.Special plunger, special custom sealed structure, good sealing effect, no oil leakage

5.The upper plate adopts six angle screws in electroplating sunk head. It is beautiful and saves space.

6. One main plate structure, oil pool, main board, oil cylinder, on one body, no seal connection.

7.Lengthening spring, the rebound effect is good, not easy to deform, can realize the oil cylinder 30mm return no deformation.

8.The Aluminum Alloy handwheel, beautiful, practical, durable, not easy to damage.

Main Specifications of Hydraulic Pellet Press:

| Model | JYP-3 | JYP-5 | JYP-12 | JYP-15B | JYP-15R |

| Pressure range | 0-3T

(0-28.8MPa) |

0-5T

(0-31.4MPa) |

0-12T(0-30MPa) | 0-15T(0-30MPa) | |

| Piston diameter | φ35mm | φ45mm | φ70mm | φ80mm | |

| Analog pressure gauge | Analog pressure gauge is included in the standard package, dual scale display: Mpa and Ton | ||||

| Digital pressure gauge

(optional) |

Digital display 0.00-40.00mpa, accuracy 0.01Mpa (only with “s” type) | ||||

| Maximum piston stroke | 30mm | ||||

| Pressurization mode | Manual pressurization / manual slow pressurization | ||||

| Pressure stability | ≤1MPa/10min | ||||

| Overall structure | Patented technology of integrated structure, no sealing connection of equipment, reducing oil leakage point | ||||

| Diameter of worktable | φ80mm | φ90mm | |||

| Number of columns | 2 columns | 2columns | 4 columns | ||

| Working space

(W×H) |

96×130mm | 96×130mm) | 140×150mm | 80×130mm | |

| Machine dimensions

(L×W×H) |

225×155×380mm | 225×155×380mm | 245×175×390mm | 245×175×390mm | |

| Machine weight | 28kg | 28kg | 38kg | 40kg | |

| Model | JYP-24 | JYP-30 | JYP-40 | JYP-60 | |

| Pressure range | 0-24T(0-34MPa) | 0-30T(0-31.5MPa) | 0-40T(0-30MPa) | 0-60T(0-34MPa) | |

| Piston diameter | φ95mm | φ110mm | φ130mm | φ150mm | |

| Analog pressure gauge | Analog pressure gauge is included in the standard package, dual scale display: Mpa and Ton | ||||

| Digital pressure gauge

(optional) |

Digital display 0.00-40.00mpa, accuracy 0.01Mpa (only with “s” type) | ||||

| Maximum piston stroke | 30mm | 40mm | 50mm | 50mm | |

| Pressurization mode | Manual pressurization / manual slow pressurization | ||||

| Pressure stability | ≤1MPa/10min | ||||

| Overall structure | Patented technology of integrated structure, no sealing connection of equipment, reducing oil leakage point | ||||

| Diameter of worktable | φ105mm | φ120mm | φ140 | φ160mm | |

| Number of columns | 4 columns | ||||

| Working space

(W×H) |

80×150mm | 92×160mm | 115×185mm | 185×250mm | |

| Machine dimensions

(L×W×H) |

245×175×415mm | 275×195×420mm | 295×215×500mm | 405×240×565mm | |

| Machine weight | 42kg | 56kg | 75kg | 120kg | |

Applications:

Manual Hydraulic Pellet Press is widely used in various fields such as scientific research, teaching, testing, catalysis, pharmaceuticals, chemical engineering, and the development of new materials.

Additionally, by using specific tablet pressing molds, it can compress various powder materials, such as potassium bromide (KBr), sodium chloride (NaCl), boric acid (H3BO3), into various shapes, producing experimental samples, cylinders, irregular shapes, or other forms.

Simultaneously, it is suitable for workplaces requiring corresponding pressure, serving as a press to test the compressive strength of various objects and more. Its applications are extremely diverse.