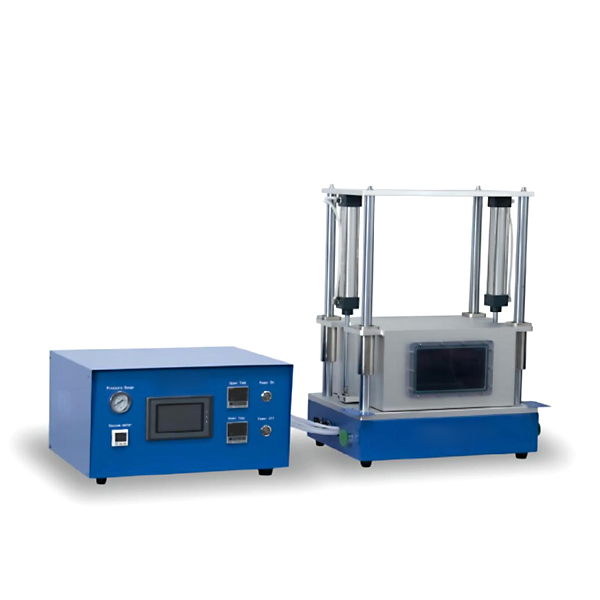

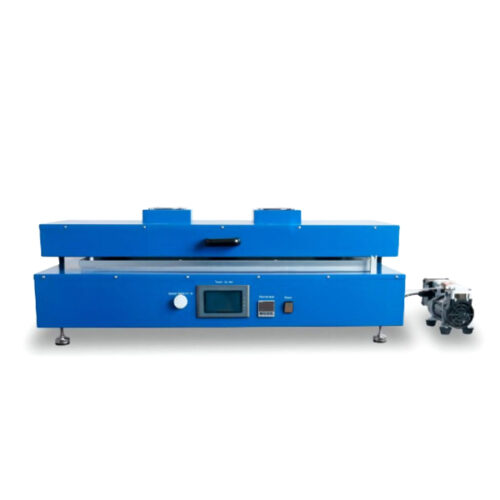

Battery Vacuum Liquid Injection & Hot Sealing Machine

Applications:

This vacuum liquid injection & hot sealing machine is primarily designed for the absorption of electrolyte during the injection process of pouch and cylindrical batteries. It facilitates a more complete fusion with the electrode sheets in a vacuum environment. Additionally, it is suitable for the vacuuming and heat-sealing pre-encapsulation of pouch batteries after electrolyte injection. The machine achieves this through precise control of the vacuum pumping box and pneumatic heat-sealing components, automatically completing the vacuum heat-sealing of the aluminum-plastic shell of the battery.

Features and Benefits:

1.The sealing head is made of copper for efficient heat transfer, saving energy and improving work efficiency, making it more energy-efficient compared to similar products.

2.The pressure of the upper and lower sealing heads can be adjusted through a pressure regulating valve to meet different process parameter requirements.

3.The upper and lower sealing heads are driven by cylinders and guided by two linear guide sleeves, ensuring flexible movement and accurate guidance to meet the parallelism requirements after sealing.

4.Changes inside the chamber can be observed through a transparent window during operation.

5.It can adapt to batteries of different specifications, and adjustment is simple and convenient.

6.The machine adopts a split design of the main unit and control box, allowing it to work inside a glovebox or on a production line.

7.The product features multi-cycle operation, aiding in more thorough fusion of the electrolyte.

8.The upper chamber is driven by a cylinder and guided by two linear guide sleeves, ensuring flexible movement and accurate guidance to meet the sealing requirements.

9.It has an attractive appearance, compact size, and light weight.

10.PLC + touchscreen control for easy and intuitive operation.

Technical Parameters:

PLC touchscreen for automated control

Chamber made of corrosion-resistant aluminum alloy with robust structure

Adjustable settling time and pressure

Vacuum degree up to -95KPa (buyer to provide vacuum pump)

Sealing head temperature: Room temperature to 260℃, adjustable

Temperature control accuracy: ±2℃

Heat-sealing pressure: Adjustable from 0 to 7Kg/cm2

Heat-sealing time: Adjustable from 0 to 9995

Sealing width: 3-15mm (customizable based on customer requirements)

Maximum (effective) sealing size: 180mm

Seal blade length: 200mm

Maximum battery discharge size: 200mm x 200mm (including gas bubble position)

Seal thickness range: 60-500um

Seal thickness uniformity: <15um difference between any two points

Air consumption: Approximately 0.2L compressed gas per sealing cycle

Power consumption: Around 0.6KW during heating with a 300W heating tube

Power supply: 220V/50Hz

Compressed air source: 0.4-0.7Mpa, for use inside the glovebox

Chamber volume: L425mm x W350mm x H170mm

Equipment dimensions:

Action part of the chamber: Approximately L600mm x W450mm x H630mm

Control part: Approximately L560mm x W220mm x H340mm

Weight: 130KG