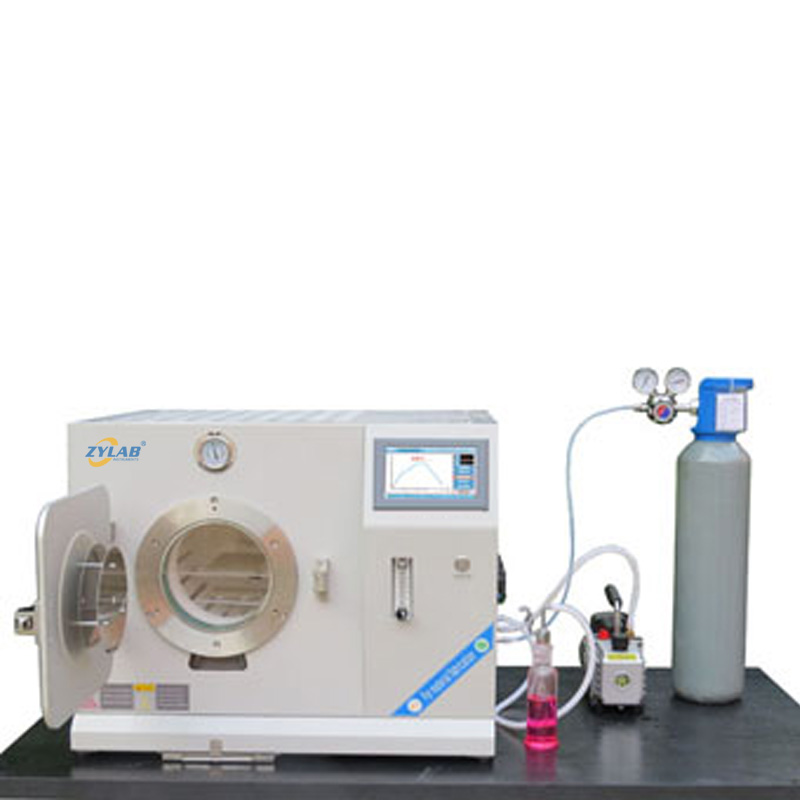

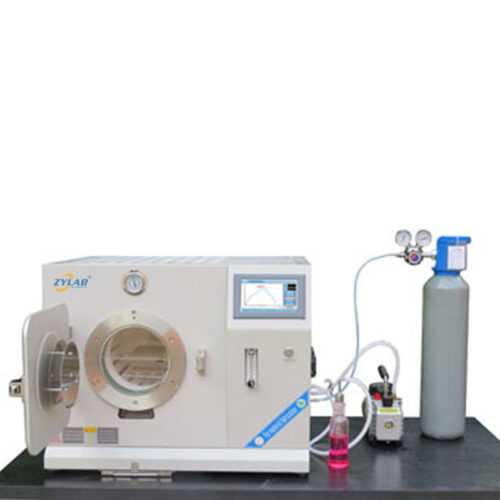

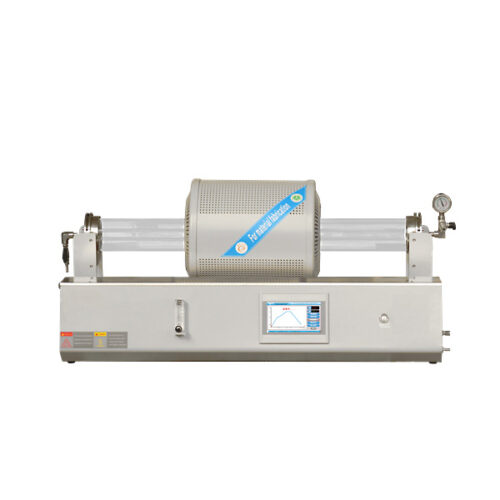

1200.C Vacuum Horizontal Tubular Furnace

Introduction:

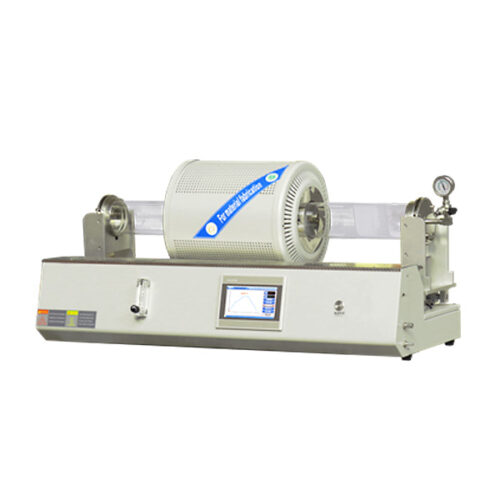

This Vacuum Horizontal Tubular furnace is suitable for sample preparation of various materials in clean environment. The product is uniformly heated outside the vacuum chamber of high purity quartz by annular heating wire, with high thermal efficiency, fast heating speed and good temperature uniformity. The internal circulation of protective atmosphere is uniform. High temperature resistant sealing ring and water-cooled stainless steel sealing system are adopted for sealing parts, which are safe and reliable.

And the furnace has a complete automatic touch screen operation performance, and has the alarm function of over temperature, broken couple and low water pressure.

The heating system and the control unit are reasonably separated and do not interfere with each other, which can ensure that the electric heating element and the entire circuit system maintain a safe and reliable working state in a continuous high temperature environment.

The large-diameter quartz vacuum chamber can process large-size thin-walled samples with uniform heating and good sintering effect.

Main Features:

1. Unique style, more humanized structure design;

2. High purity quartz tube as furnace tube, max. Temperature 1200C(<1hour), working temperature Rt –1100C.

3. 30 segments programmable and auto control.

4. 7”Color touch screen LCD intelligent man-machine English interface, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

5. Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different experimental processes.

6. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

7.By using special lining import from Japan and top quality resistance wire, protected against chemical contamination at the best and longer service life.

8. Furnace chamber full fiber structure, ring heating, energy saving and high efficiency

9. Double-layer thermal insulation structure, with air-cooled interlayer, to ensure the surface of furnace below 50.C, safety for the operator.

10. Perfect protection measures for over-temperature, short couple and cooling water cut, safe and worry-free!

11. With gas flowmeter, atmosphere sintering more convenient.

12. The temperature measuring hole and the observation window are interchangeable (single choice).

13. Low power consumable, exquisite structure, and large capacity, it is the ideal vacuum horizontal tubular furnace for labs and production enterprise.

Technical Parameters:

| Model | VAH1200-20IT |

| Product Name | 1200.C Vacuum Horizontal Tubular Furnace |

| Chamber Material | Imported high quality alumina fiber refraction insulation |

| Heating Element | Top quality resistance wire |

| Max.temperature | 1200.C |

| Working Temperature | RT-1100.C |

| Heating Rate | ≤20.C/min(advice:10.C/min) |

| Heating zone size(mm) | Φ200*200mm(6L) |

| Tube Material | High purity quartz |

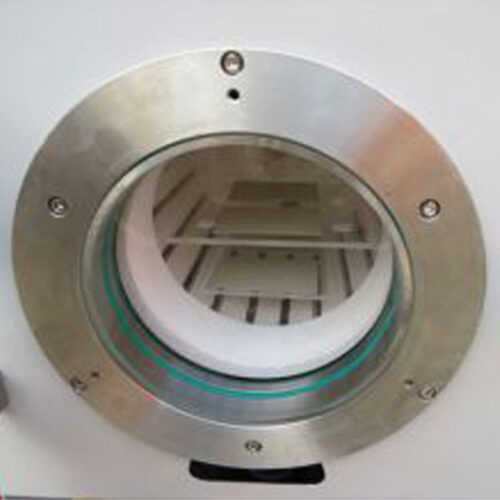

| Sealing Mode | Vacuum stainless steel sealing flange |

| Vacuum Degree | ≤10Pa |

| Control Mode | 7 inch Touch Screen, Intelligent PID Control |

| Operating Interface | English Graphical Interface |

| Temperature Accuracy | +/- 1.C |

| Presetting Curve | 15 Presetting Curve, 30 Segments Programmable |

| Protection Setting | Over Temperature Alarm, Over Current Protection, Broken Thermocouple Protection |

| Thermocouple | K Type |

| Certification | ISO |

| Working Voltage | AC 208-240V 50/60 Hz (as required) |

| Power | 3.5KW |

| Dimension | 780(W) * 580(H) * 600(D)mm |

| Weight | 60kgs |

| Standard Accessories | Quartz Tube, Vacuum Flange, Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |

| Warranty | 12 months(not including consumable parts, such as quartz tube, heating elements, thermocouple, etc), lifetime support. |

Applications:

Vacuum horizontal tubular furnaces find applications in various fields due to their ability to provide controlled high-temperature environments. Some of the common applications include:

1. Materials Research:

In scientific research, these furnaces are utilized for the synthesis and processing of advanced materials, including nanomaterials, ceramics, composites, and metal alloys.

2. Heat Treatment:

Vacuum horizontal tubular furnaces are used for annealing, sintering, and brazing of metals and other materials, ensuring controlled heating and cooling processes.

3. Chemical Vapor Deposition (CVD):

CVD processes are conducted in the furnace to grow thin films and coatings on substrates, essential in semiconductor manufacturing and other surface engineering applications.

4. Crystal Growth:

These furnaces are employed in crystal growth processes, including the growth of semiconductor crystals for electronic devices.

5. Semiconductor Processing:

In semiconductor manufacturing, these furnaces are used for diffusion, oxidation, and other thermal processes to fabricate semiconductor devices like diodes and transistors.

6. Carbonization and Graphitization:

Carbon materials, such as carbon nanotubes and graphene, can be produced using high-temperature carbonization and graphitization processes.

7. Pyrolysis:

These furnaces can be utilized for pyrolysis reactions, converting organic materials into solid carbon and gaseous products.

8. Catalysis:

Catalytic reactions can be performed in the furnace under controlled temperature and pressure conditions to study and optimize catalytic processes.

9. Research in Chemistry and Physics:

Vacuum horizontal tubular furnaces are used in various chemical and physical experiments that require high-temperature conditions.

10. Glass Annealing and Forming:

Glass materials can be annealed or shaped within the furnace to achieve specific properties and shapes.

11. Aerospace and Advanced Materials:

In aerospace research and development, these furnaces play a crucial role in studying and manufacturing advanced materials for high-temperature applications.

12. Powder Metallurgy:

Powdered metal materials can be sintered to form dense and strong components in the furnace.

13. Environmental Testing:

Some materials and components may be subjected to extreme temperature conditions for environmental testing purposes.

These are just a few examples, and the applications of vacuum horizontal tubular furnaces continue to expand as researchers and industries explore new possibilities for high-temperature processes and materials.