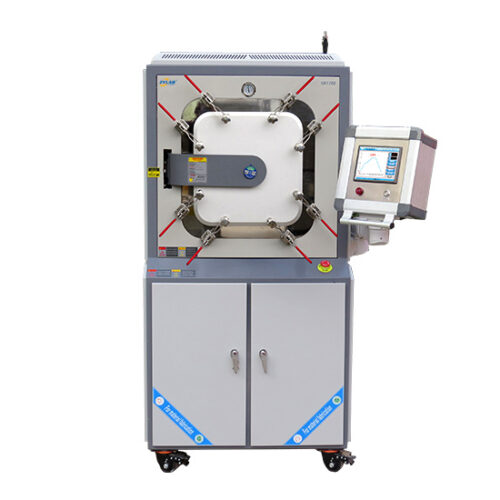

ZYLAB 1200°C High Uniformity Box Furnace

Introduction

ZYLAB High Uniformity Box Furnace is designed with precision and uniform heat treatment in mind, particularly ideal for the annealing of high-temperature alloys and precious metals.

Equipped with a 5-side heating system, this furnace provides consistent thermal performance for your materials. The high maximum temperature of 1200°C and a spacious 64L chamber make it a perfect solution for laboratory research, sintering, and industrial heat treatments. Its advanced PID control ensures precise temperature management, meeting the strict demands of alloy and metal processing.

Key Features

1. 5-Side Heating Design

-

Uniform Temperature Distribution: Five-sided heating (bottom, front, rear, left, and right) ensures minimal temperature gradients and highly uniform heating.

-

Rapid Heating: Optimized heating elements for faster temperature rise, improving process efficiency.

2. Precision Temperature Control

-

PID Controller: Advanced digital PID system ensures temperature accuracy of ±1°C, ideal for sensitive annealing processes.

-

K-Type Thermocouple: Monitors temperature in real time for precise feedback and control.

3. High-Quality Furnace Chamber

-

Alumina Fiber Insulation: Exceptional thermal stability and energy efficiency for high-temperature processes.

-

64L Working Volume: Spacious chamber (400×400×400mm) accommodates a wide range of sample sizes for various heat treatment needs.

4. User-Friendly Interface

-

7” Touchscreen Display: Simple and intuitive control of heating curves, data logging, and programmable parameters.

5. Enhanced Safety Features

-

Over-temperature Protection: Automatically shuts off power if the temperature exceeds preset limits, ensuring safe operation.

-

Emergency Stop Function: Equipped with an emergency stop button for quick shutdown in critical situations.

6. Designed for Alloys & Precious Metals

-

Precise Annealing: Specifically tailored for the annealing of high-temperature alloys and precious metals, ensuring uniform treatment and optimal results.

-

Controlled Atmosphere: Optional atmosphere protection box for oxidation-sensitive materials (customizable).

Applications of High Uniformity Box Furnace

-

High-Temperature Alloys: Used for annealing and heat treatment of superalloys and high-temperature metals, especially in aerospace and automotive industries.

-

Precious Metals: Ideal for processing precious metals such as gold, platinum, and other valuable materials requiring precise heat treatment.

-

Metallurgy: Heat treatment of metal powders and alloys for improved mechanical properties.

-

Ceramics & Glass Processing: Sintering and crystallization of ceramics and glass materials.

-

Materials Science: Used in laboratories for research on new materials and their behavior under high temperature conditions.

Technical Specifications of High Uniformity Box Furnace

| Model | M1200-40 (Benchtop) | |

| Power Supply | Three-phase, 380V, 50Hz | |

| Rated Power | 10 kW | |

| Heating Zones | Single zone, single control (5-side heating) | |

| Temperature Accuracy | ±1°C | |

| Thermocouple Type | K-type (φ2 × 600 mm) | |

| Maximum Temperature (Tmax) | 1200°C | |

| Rated Operating Temperature | 1150°C | |

| Recommended Heating Rate | ≤10°C/min | |

| Furnace Chamber Dimensions | 400 mm (L) × 400 mm (H) × 400 mm (D) | |

| SiC Shelf Plate Size | 390 mm (L) × 10 mm (H) × 390 mm (D) | |

| External Dimensions | 856 mm (L) × 1100 mm (H) × 753 mm (D) | |

| Net Weight | Approximately 320KG | |

| Control System |  |

|

| Heating Element |  |

Mo-doped Fe-Cr-Al alloy heating wire |

| Atmosphere Protection Box(Optional) |  |

Designed to create a controlled atmosphere inside the chamber. Prevents oxidation, contamination, and undesired reactions during heating. Customizable sizes available. |

| Temperature Uniformity Testing |  |

|

| Safety Notice |

|

|

| Warranty & Support | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. | |

Customization Options

ZYLAB offers flexible customization to meet a wide range of research and industrial processing needs. Optional features include:

-

Gas Inlet for Inert Atmosphere

Add a gas inlet to introduce inert gases such as argon or nitrogen for protective or purging purposes, and to help accelerate exhaust gas removal during heat treatment. -

Exhaust Outlet

Integrated gas exhaust port effectively removes by-products generated during material sintering or thermal processing, keeping the chamber environment clean and stable. -

Custom Chamber Size

The furnace chamber can be tailored to specific dimensions, accommodating various material sizes and process requirements.

Advantages of ZYLAB Furnaces

-

Flexible Customization – Designed to meet diverse laboratory demands

-

Widely Used in Research and Industry – Reliable performance in materials labs, universities, and production environments

-

Professional Support – Dedicated technical service and documentation

-

Efficient Logistics – Timely delivery and global shipment options

For More Content

Please read our blog: A Comprehensive Guide to Box Furnaces

For More Options on Box Furnaces

Please visit our website [Box Furnaces]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]