Advanced High Temperature Chamber Furnace with Protective Gas Control System

Introduction

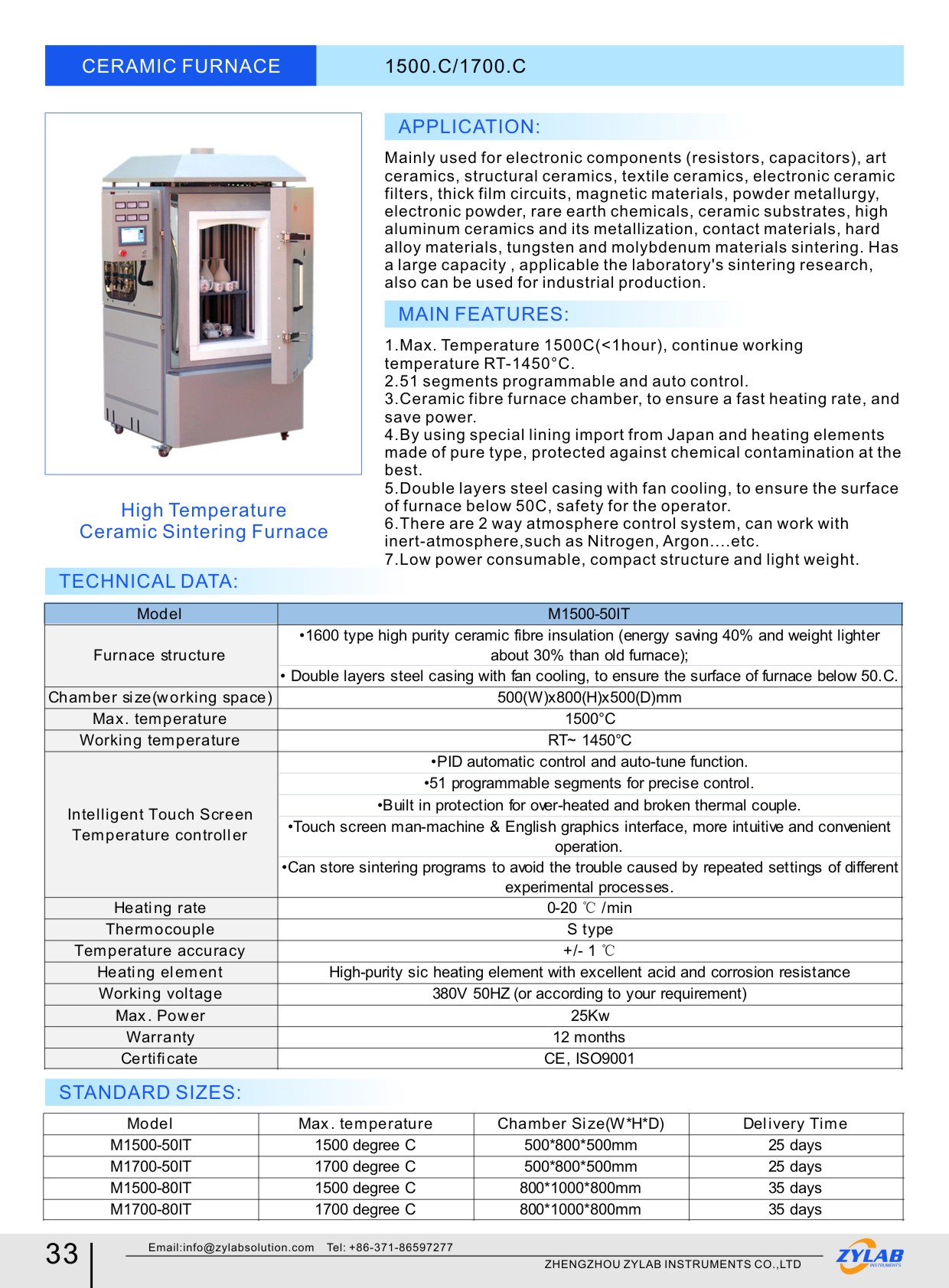

This High Temperature Chamber Furnace has ample room, available for both laboratory sintering studies and industrial production.

It’s mainly used in electronic components (resistors, capacitors), art ceramics, structural ceramics, textile ceramics, electronic ceramic filters, thick film circuits, magnetic materials, powder metallurgy, electronic powder, rare earth chemicals, ceramic substrates, high aluminum ceramics and its metallization, contact materials, hard alloy materials, tungsten, molybdenum and other materials industry sintering preparation.

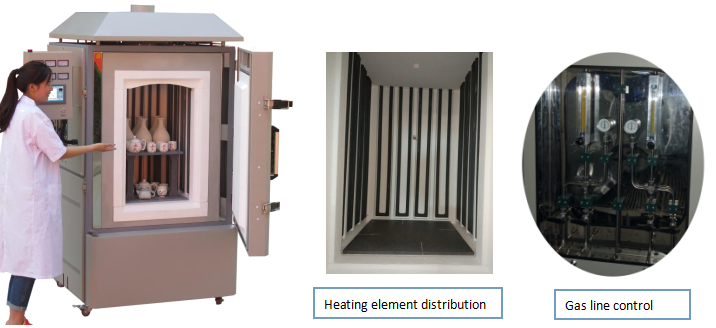

Structure of High Temperature Chamber Furnace

Key Features of High Temperature Chamber Furnace

- High-Temperature Performance: Maximum temperature of 1500°C, with a continuous operating range from room temperature to 1450°C.

- Advanced Programmable Control: Features a 30-segment programmable controller for precise temperature management and automated operation.

- Efficient Heating & Energy Saving: The ceramic fiber furnace chamber ensures rapid heating while reducing power consumption.

- Superior Lining & Heating Elements: Incorporates special lining and high-purity heating elements, effectively preventing chemical contamination and enhancing durability.

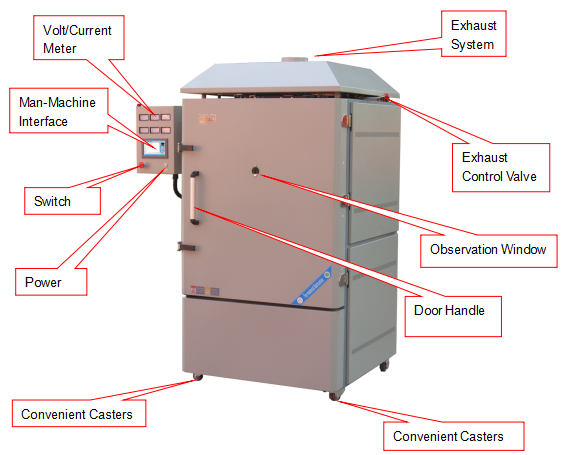

- Safe & Cool Exterior: The double-layer steel casing with fan cooling keeps the outer surface temperature below 50°C, ensuring operator safety.

- Dual Atmosphere Control: Equipped with a two-way atmosphere system, supporting inert gases such as Nitrogen, Argon, etc.

- Effective Exhaust System: A top-mounted exhaust chimney efficiently removes volatiles generated during sintering.

- Modern & Practical Design: Features a sleek, innovative appearance combined with practical functionality.

Specifications of High Temperature Chamber Furnace

| Model | M1500-50IT |

| Furnace Structure | •1600 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

500(W)x800(H)x500(D)mm |

| Max Working Temperature | 1500°C |

| Continue

Working Temperature |

RT~ 1450°C |

| Heating Elements | High-purity sic heating element with excellent acid and corrosion resistance, 3 sides heating |

| Intelligent Touch Screen

Temperature controller |

•PID automatic control and auto-tune function. •30 programmable segments for precise control. •Built in protection for over-heated and broken thermal couple. •Touch screen man-machine & English graphics interface, more intuitive and convenient operation.•.Can store 30 sintering programs, and has the function of USB interface derived data. |

| Working Voltage | 380V 50HZ(or as requirement) |

| Rated Power | 25kw |

| Heating Rate | 0~15℃/min |

| Temperature Accuracy | ±1℃ |

| Thermal Couple | S type |

| Temperature Uniform | ±3℃ |

| Warranty | 18 months(not including consumable parts, such as heating elements, thermocouple, etc), lifetime support. |

| Certificate | ISO |

Standard Size and Delivery Time

| Model | Max. temperature | Chamber Size(W*H*D) | Delivery Time |

| M1500-50IT | 1500 degree C | 500*800*500mm | 25 days |

| M1700-50IT | 1700 degree C | 500*800*500mm | 25 days |

| M1500-80IT | 1500 degree C | 800*1000*800mm | 35 days |

| M1700-80IT | 1700 degree C | 800*1000*800mm | 35days |

Which kinds of industry can use this High Temperature Chamber Furnace?

Education, Research, Ceramic, etc.

Applications of High Temperature Chamber Furnace

Mainly used in electronic components (resistors, capacitors), art ceramics, structural ceramics, textile ceramics, electronic ceramic filters, thick film circuits, magnetic materials, powder metallurgy, electronic powder, rare earth chemicals, ceramic substrates, high aluminum ceramics and its metallization, contact materials, hard alloy materials, tungsten, molybdenum and other materials industry sintering preparation.