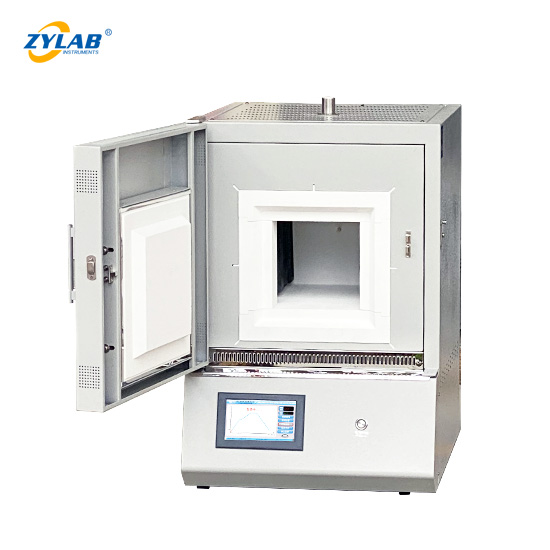

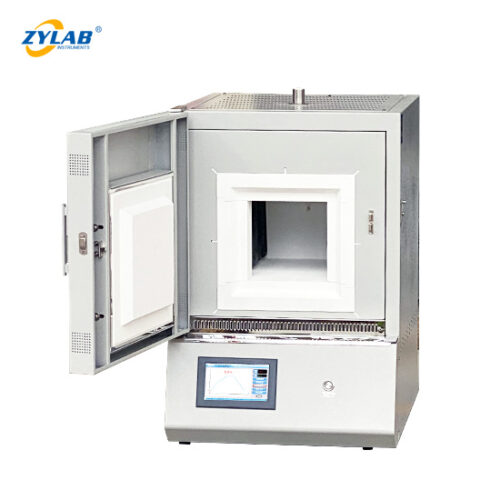

ZYLAB 1500°C High Temperature Box Furnace

Introduction

ZYLAB High Temperature Box Furnace offers precise and reliable heat treatment for materials requiring temperatures up to 1500°C. With a 12-liter chamber capacity, this compact yet powerful muffle furnace is ideal for use in research laboratories, quality control, ceramics sintering, and metallurgical testing.

Built with advanced insulation materials and high-purity heating elements, the furnace ensures excellent temperature uniformity and long-term stability. Its intuitive control interface and robust design make it an excellent choice for demanding high-temperature applications.

Key Features

-

High Maximum Temperature – Up to 1500°C

Suitable for high-temperature sintering, annealing, and material testing applications. -

12L Chamber Capacity

Optimized internal space for mid-sized samples or crucibles. -

7-Inch Color Touchscreen Controller

Intuitive interface with real-time temperature display, program memory, and precise PID control. -

30-Segment Programmable Logic

Enables automatic execution of custom heating profiles for consistent and repeatable results. -

Durable Ceramic Fiber Chamber

Offers low thermal conductivity, fast heat-up rates, and improved energy efficiency. -

Premium Silicon Carbide Heating Elements

Equipped with high-purity SiC rods featuring excellent acid resistance and corrosion resistance, ensuring durability and clean thermal processing. -

Double-Layer Steel Casing with Cooling Fan

Keeps the exterior surface temperature below 50°C to ensure safe operation in lab environments. -

Top-Mounted Exhaust Chimney

Efficient removal of gases and fumes generated during heat treatment processes, improving workplace safety and sample integrity. - Customizable Chamber Dimensions

Furnace chamber size can be tailored to meet specific experimental or production requirements.

Applications of High Temperature Box Furnace

-

Sintering of Advanced Ceramics – Processing of materials such as alumina, zirconia, and other technical ceramics

-

Powder Metallurgy – Debinding and sintering of metal powders and complex parts

-

Battery Materials Sintering – Heat treatment of lithium battery cathode/anode materials and solid-state electrolytes

-

Glass and Enamel Firing – Suitable for specialty glass products, glaze testing, and thermal coatings

-

Thermal Analysis and Material Testing – For R&D labs to evaluate thermal behavior and structural changes

-

Crystallization and Phase Transformation Studies – Supporting research in materials science and solid-state physics

-

Heat Treatment of Refractory Materials – Ideal for corrosion-resistant and high-temperature materials processing

Technical Specifications of High Temperature Box Furnace

| Model | M1500-22 | |

| Working voltage | 380v 50Hz (or according to requirement) | |

| Max. Power | 5.5KW | |

| Maximum Temperature | 1500°C | |

| Continuous Working Temp | 1450°C | |

| Recommended Heating Rate | ≤10°C/min | |

| Chamber Size | 220 × 220 × 300 mm | |

| Overall Dimensions | 640 (W) × 870 (H) × 720 (D) mm | |

| Temperature Controller |  |

|

| Temperature Accuracy | ±1°C | |

| Heating Element | High-density silicon carbide rods | |

| Net Weight | 115 kg | |

| Safety Notice |

|

|

| Warranty & Support | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. | |

Advantages of ZYLAB Furnaces

-

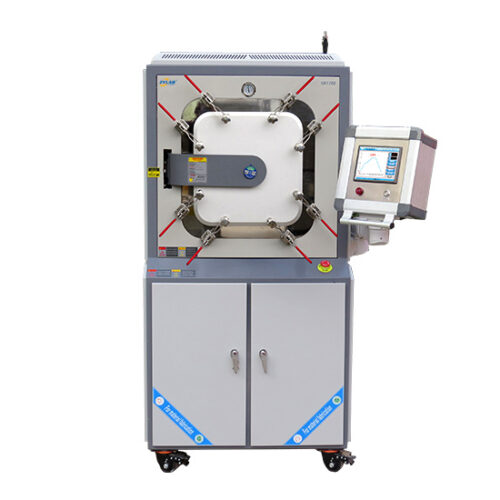

Flexible Customization – Designed to meet diverse laboratory demands

-

Widely Used in Research and Industry – Reliable performance in materials labs, universities, and production environments

-

Professional Support – Dedicated technical service and documentation

-

Efficient Logistics – Timely delivery and global shipment options

For More Content

Please read our blog: A Comprehensive Guide to Box Furnaces

For More Options on Muffle Furnaces

Please visit our website [Box Furnace]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]