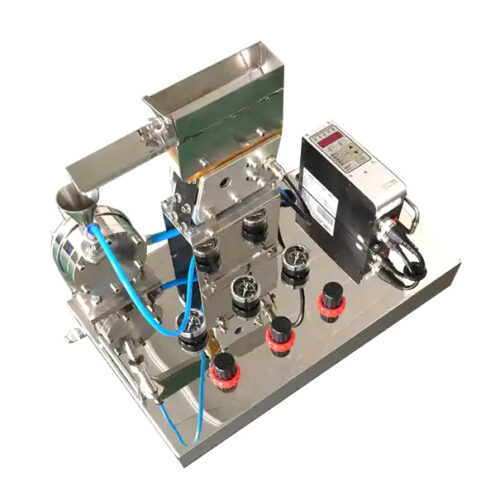

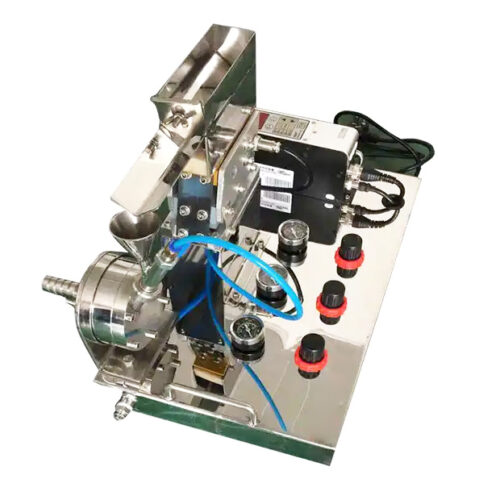

Speed 1600rpm Nano-level Grinding Ultra High Energy Ball Mill

Introduction:

High Energy Ball Mill is a new generation planetary ball mill capable of rapidly grinding samples in a short time, with speeds reaching up to 1600 r/min. It features independent speeds for both planetary and jar rotations, allowing for the adjustment of impact and shear forces during the milling process for various materials. This enables optimized particle size and shape, achieving superior mechanical alloying.

Mechanical alloying is a solid-state powder processing technique where metal powder mixtures undergo repeated cold welding and fracturing under high-energy ball milling conditions to create alloys. This method allows for the synthesis of various equilibrium and non-equilibrium alloys starting from mixed elemental or pre-alloyed powders and is used to coat alloyed powder materials. Mechanical alloying is a method specific to metal powder processing and is commonly employed to prepare high-temperature alloys. It has been successfully applied in the preparation of alloys used in aerospace components designed for high-temperature conditions.

Applications:

High Energy Ball Mill is applied to Nano materials, MLCC, zinc oxide powder, cobalt oxide powder, Ni-Zn ferrite, Mn-Zn ferrite chemicals, catalysts, building materials minerals and metallurgy and metal electronic alloys, coal mines, coke, iron ore, metal oxides, quartz, semi-precious stones, slag, magnetic materials, lithium cobalt oxide, lithium manganese oxide, catalysts, phosphors, Long afterglow photoluminescent pigment, rare earth polishing powder, electronic glass powder, fuel cells, zinc oxide varistors, etc.

Features and Benefits of High Energy Ball Mill:

- High-energy speed revolution 0-600/rotation 0-1600, infinitely adjustable.

- Ratio of revolution to rotation 1: 2.6.

- Equipped with emitr remote control system, intelligent control with computers, mobile phones, PAD and other terminals.

- Dry grinding, wet grinding, vacuum grinding, atmosphere protection grinding.

- Intelligent digital one-button operation, simpler.

- Can store 3 modes and 15 schemes, with power-off protection memory self-start function.

- Cover opening safety switch and operation self-locking function design to ensure safety.

Technical Parameters of High Energy Ball Mill:

| Model | ZYLAB-M1600-2L |

| Sample characteristics | Hard, medium-hard, soft, brittle, elastic, fibrous |

| Treatment principle | Impact force, shear force, friction force |

| Processing type | Crushing, grinding, mixing, homogenization, mechanical alloying |

| Maximum Sample Size | Brittle materials <10mm, other materials <3mm |

| Final Particle Size | ~0.1um (Wet grinding <1 µm; Dry grinding <20 µm) |

| Grinding Jar Volume | 4*(50ml/100ml/250ml/500ml) |

| Number of Grinding Jars | Two or four |

| Jar Materials | Stainless steel, agate, zirconia, corundum, tungsten carbide, nylon, polyurethane, PTFE, silicon carbide, etc. |

| Grinding Ball Configuration | 1: For the crushing stage

2: For the grinding stage 3: For nano-dispersion (Due to the varying material characteristics, please consult the sales service for specific recommendations.) |

| Ball diameter | 1/2/3/5/8/10/15/20/25/30mm |

| Dimensions (length, width and height) | 770*718*875mm |

| Net weight | 300kg |

| Velocity of revolution (r/min) | 0-600 |

| Rotation speed (r/min) | 800-1600 |

| Revolution/Rotation Speed Ratio | 1 : 2.66 |

| Power (Kw) | 4.4KW |

| Power Supply (v/Hz) | AC220v, 50/60Hz |

Other Optional Model:

| Model | Grinding Jar Capacity | Vacuum Jar Capacity | Revolution speed | Rotation speed | Power | Voltage | Weight |

| M1600-0.4L | 50-100(ml) | 50(ml) | 0-600(r/min) | 0-1600(r/min) | 2.2(kw) | 220/50(v/hz) | 200(kg) |

| M1600-1L | 50-250(ml) | 50-100(ml) | 0-600(r/min) | 0-1600(r/min) | 2.2(kw) | 220/50(v/hz) | 210(kg) |

| M1600-2L | 50-500(ml) | 50-250(ml) | 0-600(r/min) | 0-1600(r/min) | 4.4(kw) | 220/50(v/hz) | 300(kg) |