Laboratory Stainless Steel Vacuum Glove Box

Introduction:

Glove box, also known as glovebox or isolator, is a sealed container with built-in gloves that allows a person to manipulate objects in a controlled environment, typically to work with hazardous materials or to protect the contents from contamination. The gloves are attached to openings in the front of the box, enabling the user to interact with the materials inside while maintaining a barrier between the user and the contents.

Characteristics of ZYLAB Gloxe Box :

Chamber:

Constructed with SUS304 stainless steel, with a thickness of 3mm. The interior surface undergoes a stainless steel brushed treatment, while the exterior surface is painted in white.

Windows:

Equipped with 10mm thick acrylic windows on the front side, providing a broad and unobstructed view.

Ball Valves:

Inlet and outlet valves are made of 304 stainless steel, featuring inner and outer water nozzles for water and air intake. Certain instruments (e.g., spin coater) can be placed inside the chamber and operated under vacuum.

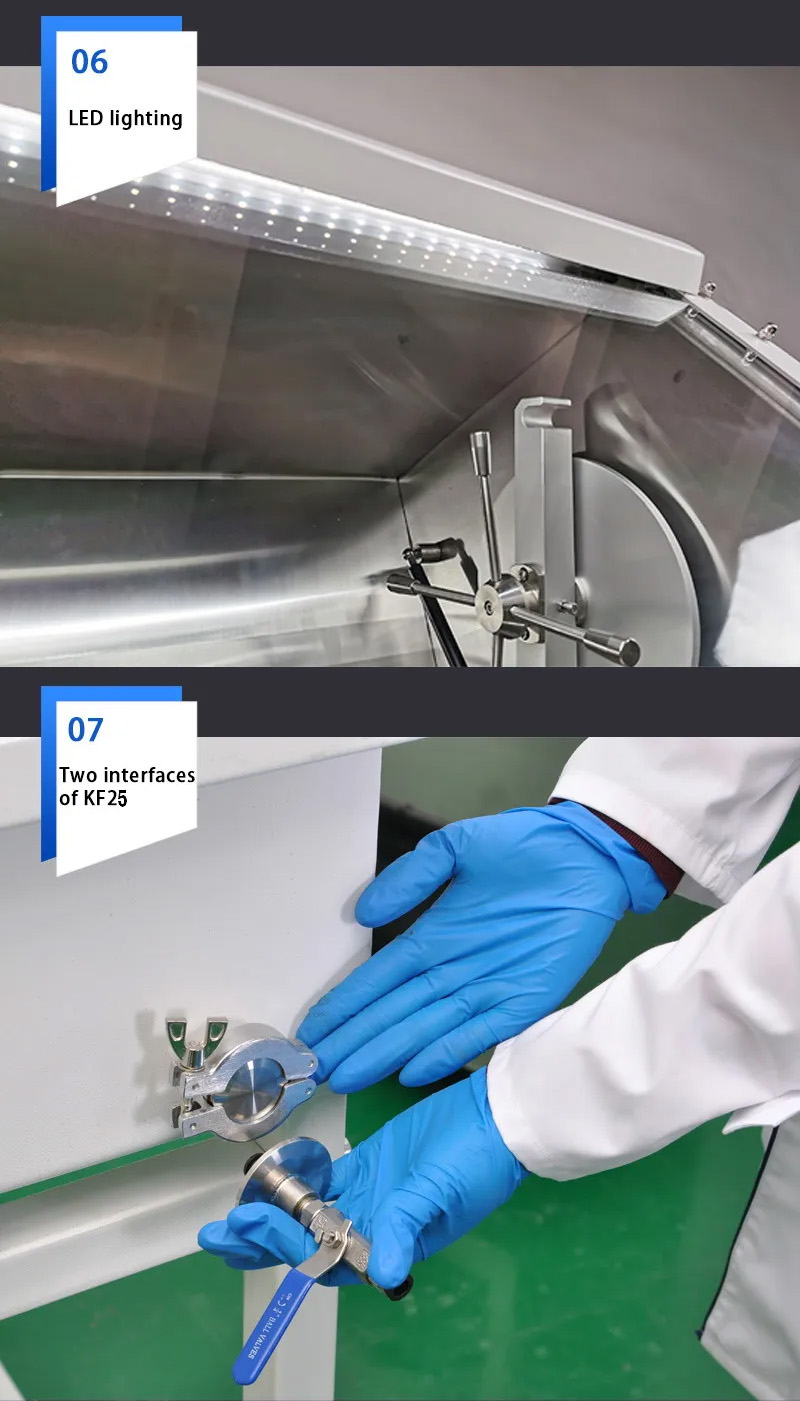

Lighting:

Utilizes UV-free white light, installed above each glass window.

Power Supply:

Multiple porous power sockets are installed inside the chamber to meet the power requirements of internal instruments.

Gloves:

Operational glove box features industrial-grade corrosion-resistant latex gloves, with a sealed ring fixing the glove port.

Reserved Interface:

Reserved KF interfaces allow for future upgrades of the glove box.

Optional Features:

- Fully Automatic Humidity System: Controls humidity levels within the chamber, eliminating humidity fluctuations.

- Fully Automatic Pressure System: Maintains a constant pressure within the chamber, particularly useful for preventing the release of harmful powders.

- Drying Oven: Offers an overheating compartment for vacuum drying, if necessary.

- Purification System: After vacuuming inert gas, water and oxygen levels remain around 200PPM. The purification system can achieve water and oxygen levels below 1PPM.

- Dust Removal System: Achieves internal cleanliness levels of class 100/1000; an optional dust removal system is available.

Main Specifications:

| Type A | |||||

| Model | Main Chamber Dimensions (mm) | Optional Side Opening Door | Vacuum Level | Transfer Chamber Dimensions (mm)) | Transfer Chamber Vacuum Level |

| VGB-1A | 600W*450D*420H | 300H*260D | -0.1MPA | None | |

| VGB-3A | 780W*650D*700H | 350H*300D | -0.1MPA | None | |

| VGB-4A | 1120W*740D*900H | 450H*350D | -0.1MPA | None | |

| Type B | |||||

| Model | Main Chamber Dimensions (mm) | Optional Side Opening Door | Vacuum Level | Transfer Chamber Dimensions (mm)) | Transfer Chamber Vacuum Level |

| VGB-1B | 600W*450D*420H | 300H*260D | -1000PA | Ф210*260L | -0.1MPA |

| VGB-3B | 780W*650D*700H | 350H*300D | -1000PA | Ф240*260L | -0.1MPA |

| VGB-4B | 1120W*740D*900H | 450H*350D | -1000PA | Ф385*400L | -0.1MPA |

| Type C | |||||

| Model | Main Chamber Dimensions (mm) | Optional Side Opening Door | Vacuum Level | Transfer Chamber Dimensions (mm)) | Transfer Chamber Vacuum Level |

| VGB-1C | 600W*450D*420H | 300H*260D | -0.1MPA | Ф210*260L | -0.1MPA |

| VGB-3C | 780W*650D*700H | 350H*300D | -0.1MPA | Ф240*260L | -0.1MPA |

| VGB-4C | 1120W*740D*900H | 450H*350D | -0.1MPA | Ф385*400L | -0.1MPA |

Controller Parameters:

| Series | Controller Parameters | |

| Display Type | Water Content Analyzer: Monitors temperature and humidity in the range of 1-99% RH | Oxygen Content Analyzer: Analyzes oxygen content in the range of 100PPM to 21% RH. |

|

Control Type: |

1.Fully Automatic Humidity Controller: Automatically controls the inflow and outflow of air based on the preset humidity value until the set value is reached and maintained. | |

| 2.Fully Automatic Oxygen Controller: Automatically controls the inflow and outflow of air based on the preset oxygen content value until the set value is reached and maintained. | ||

| 3.Fully Automatic Pressure Controller: Automatically adjusts the pressure inside the chamber based on the preset pressure, making experiments more convenient and straightforward. | ||

Applications:

- Chemical Research:

- Glove boxes are used in laboratories for handling and manipulating chemicals, especially air-sensitive or hazardous materials.

- Pharmaceutical Manufacturing:

- Glove boxes are employed in pharmaceutical manufacturing processes to ensure the sterility and safety of the products.

- Electronics Manufacturing:

- In the electronics industry, glove boxes are used to protect sensitive electronic components from exposure to moisture and contaminants.

- Materials Science:

- Researchers use glove boxes in materials science experiments, especially when working with materials sensitive to air or moisture.

- Biomedical Research:

- Glove boxes are utilized in biomedical laboratories for handling biological materials and conducting experiments in controlled environments.

- Nuclear Industry:

- In nuclear research and facilities, glove boxes provide a barrier for handling radioactive materials safely.

- Battery Manufacturing:

- Glove boxes are employed in the production of batteries, particularly for handling materials that react with air or moisture.

- Aerospace Applications:

- In the aerospace industry, glove boxes are used for assembling and handling components that require a controlled environment.

- Art Conservation:

- Glove boxes are used in art conservation laboratories to handle delicate artifacts and protect them from environmental contaminants.

The primary purpose of a glove box is to create a controlled environment that prevents contamination and exposure to hazardous substances, ensuring the safety of the user and maintaining the integrity of the materials or experiments inside.