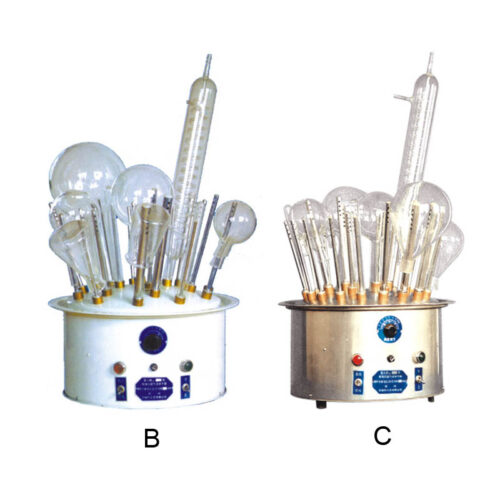

Pilot 10-200L High Borosilicate Glass Reactor Vessel

Introduction:

This series glass reactor vessel is our new single-layer glass reactor, produced on the basis of practical demands and standards of customers, absorbing advanced experience, technologies and advantages of similar products, and innovating boldly; it is not only convenient (one person can move, operate, wash, install and disassemble), but also novel and practical in structure, and it has elegant appearance, being in the lead in nation. In addition, it has become the ideal instrument in experiments and manufacturing of modern chemistry, fine chemical engineering, bio-pharmaceuticals and new material synthesis.

Glass Reactor Vessel operating principle: put reaction materials into single-layer glass reactor, and vacuumize to stirring reaction simultaneously; add water or oil into outside water or oil bath to proceed heating reaction; control evaporation and back-flow of reaction solution, and charging under constant voltage . (optional refrigeration modules matched with refrigeration sources to proceed low-temperature reaction).

Features and Benefits:

1. Glass reactor vessel body adopts high-borosilicate glass 3.3(GG-17 materials), which has superior physical and chemical performance, and transparent glass is convenient for user to observe reaction materials.

2. The shell of heating kettle is sprayed plastics to prevent corrosion, liner adopts superior stainless steel and is durable in use.

3.Rod and other accessories adopt stainless steel and aluminium alloy, elegant and secure.

4. Stainless stirring rod is coated PTFE, applied in multiple solvents stirring, which has no pollution and corrosive resistance.

5. Speed reducing and power increasing motor is stirring, and it has characteristics of running smoothly, large force moment, no-spark and long life.

6. PTFE modules and mechanical seal ensures favorable vacuum degree and long life.

7. Constant temperature oil(water) bath controls temperature intelligently, and displays oil or water temperature in bath; temperature control is realized by K sensor which is accurate. When water temperature reached pre-setting temperature, controller will cut heating source automatically; when it is lower, controller will connect heating source automatically so that water temperature is constant in tank.

8.The vacuum pressure gauge displays real-time vacuum and the pointer displays.

9.The mixing and heating double fuse has high safety protection performance.

Technical Parameters:

| Product name | High Borosilicate Glass Reactor Vessel | ||

| Model | F-10 | F-20 | F-50 |

| Vessel Capacity(L) | 10 | 20 | 50 |

| Power Supply | 220V 50HZ | 380V 50HZ | |

| Mixing Motor Power (W) | 120 | ||

| Heating Power(KW) | 3 | 5 | 8 |

| Stirring Speed(RPM) | 0~450 | ||

| Vessel Temperature Range | -80~+250.C | ||

| Bath Temperature Range | RT ~180.C | ||

| Temperature Accuracy | +/-1.C | ||

| Vacuum Level(Mpa) | 0.098 | ||

| Vessel Size(MM) | Ф280 | Ф355 | Ф470 |

| Funnel(L) | 1 | 1 | 2 |

| Overall Dimensions(mm) | 710W*440D*1900H | 810W*540D*1960H | 910W*640D*2130H |

| Net Weight(KG) | 42 | 48 | 58 |

Which kinds of industry can use this Glass Reactor Vessel?

Used in university laboratories for heating/cooling reaction materials, experimental synthesis, catalysis, or other chemical reactions under inert gas conditions.

Used in energy for fuel cells, catalytic reactions, filtration and washing, etc.

In biomedicine, it is used for chemical synthesis, reflux, distillation, concentration, crystallization, extraction, etc., and can be used in conjunction with a constant temperature circulator.

Used in cosmetics for material dispersion, emulsification, homogenization, mixing, extraction, etc.

Used for solvent recovery, single component distillation, multi-component distillation, distillation purification, or chemical synthesis in petrochemical industry

Applications of Glass Reactor Vessel:

Mainly for chemical synthesis, drying, stirring, dissolving, mixing, etc.