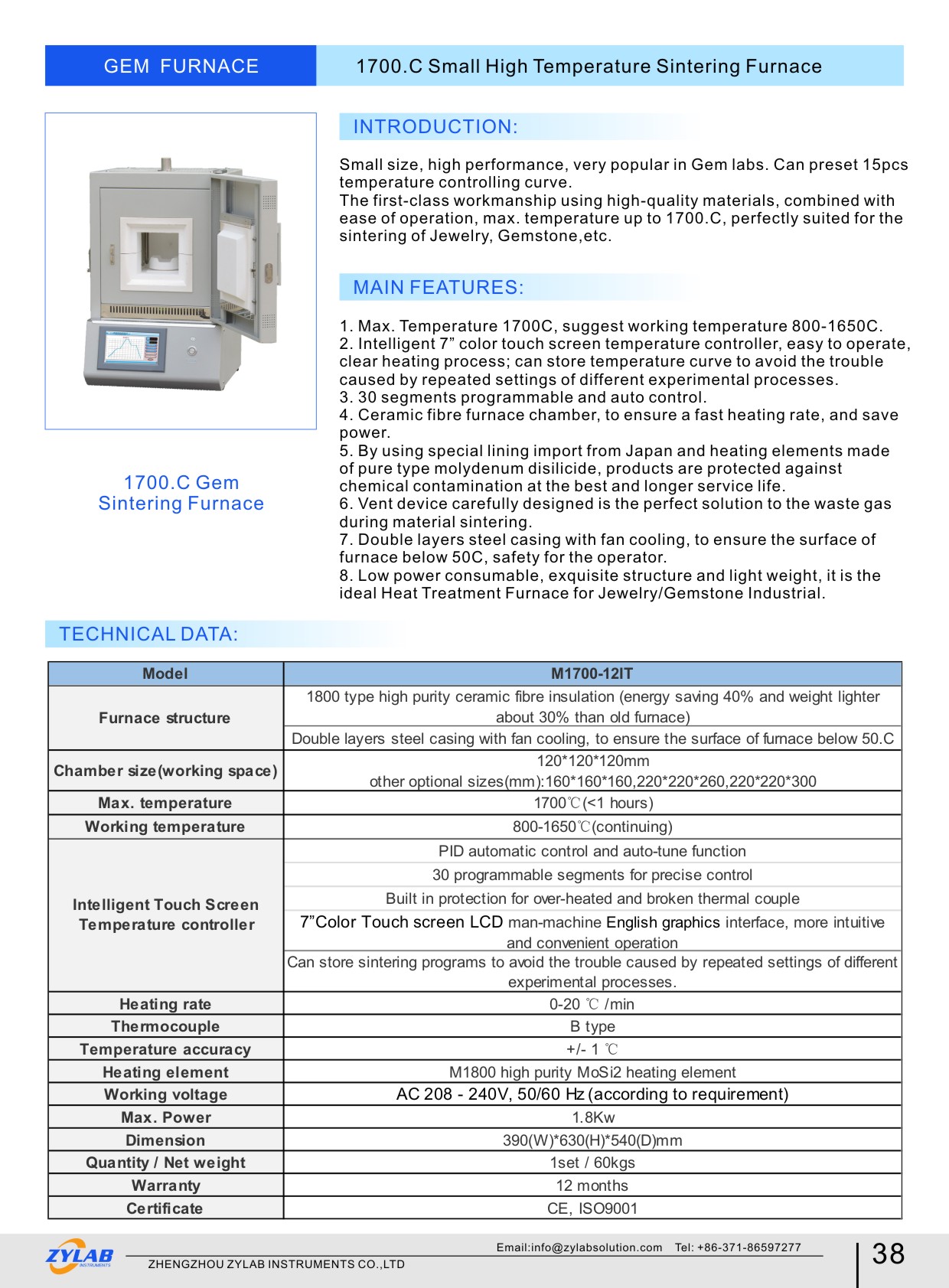

1700.C High Temperature Gem Heating Furnace

Introduction:

Small size, high performance, very popular in Gem labs. Can preset 15pcs temperature controlling curve.

The first-class workmanship using high-quality materials, combined with ease of operation, max. temperature up to 1700.C, perfectly suited for the heat treatment of Jewelry, Gemstone,etc.

Features of Gem Heating Furnace:

1. Max. Temperature 1700C, suggest working temperature 800-1650C.

2. Intelligent 7” color touch screen temperature controller, easy to operate, clear heating process; can store temperature curve to avoid the trouble caused by repeated settings of different experimental processes.

3. 30 segments programmable and auto control.

4. Ceramic fibre furnace chamber, to ensure a fast heating rate, and save power.

5. By using special lining import from Japan and heating elements made of pure type molydenum disilicide, products are protected against chemical contamination at the best and longer service life.

6. Vent hole carefully designed is the perfect solution to the waste gas during material sintering.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

8. Low power consumable, exquisite structure and light weight, it is the ideal heat treatment furnace for Jewelry/Gemstone industrial.

Technical Parameters:

| Model | M1700-12IT |

|

Furnace structure |

•1800 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

120*120*120mm(1.7L) |

| Max. temperature | 1700.C(<1 hours) |

| Working temperature | 1650.C(continuing) |

| Intelligent Touch Screen

Temperature controller |

•PID automatic control and auto-tune function. •30 programmable segments for precise control. •Built in protection for over-heated,broken thermal couple and leakage, alarm allows for operation without attendant. •Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. •.Can store sintering programs to avoid the trouble caused by repeated settings of different processes. |

| Heating rate | 0-20 ℃ /min |

| Thermocouple | B type |

| Temperature accuracy | +/- 1 ℃ |

| Heating element | M1800 high purity MoSi2 heating element |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) |

| Max. Power | 1.8Kw |

| Dimension | 390(W)*630(H)*540(D)mm |

| Quantity / Net weight | 1set / 60kgs |

| Warranty | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. |

| Certificate | CE, ISO9001 |

Applications:

The gem heating furnace has several applications within the jewelry and gemstone industry, including:

Heat Treatment of Gemstones

The primary purpose of the furnace is to heat-treat gemstones. Heat treatment can enhance the color, clarity, and overall appearance of gemstones by altering their internal structure. This process is commonly used to improve the marketability and value of gemstones.

Jewelry Manufacturing

Gem heating furnaces are essential tools in jewelry manufacturing processes. They are used to prepare gemstones for setting into various types of jewelry, such as rings, necklaces, earrings, and bracelets. Heat treatment ensures that gemstones are in optimal condition and appearance before being incorporated into jewelry pieces.

Gemstone Research and Development

Gem labs and research facilities utilize heating furnaces to study the effects of heat treatment on different types of gemstones. Researchers investigate how various heating processes affect the properties and characteristics of gemstones. This research contributes to the development of new treatment methods and enhances our understanding of gemstone behavior.

Quality Control

In commercial settings, gem heating furnaces are used for quality control purposes to ensure that gemstones meet specific standards and criteria. By subjecting gemstones to controlled heating processes, manufacturers can assess their quality, detect any defects or inconsistencies, and ensure that they meet customer expectations.

Gemstone Restoration

Gem heating furnaces can also be used for the restoration of antique or damaged gemstones. Controlled heating processes may help repair fractures, improve clarity, or remove impurities, restoring the gemstone to its original beauty and value.

Gemological Education

Gem heating furnaces are valuable tools in educational institutions offering courses in gemology, jewelry design, and gemstone appraisal. Students can gain hands-on experience with heat treatment techniques and learn how to evaluate the effects of heating on different types of gemstones.

Overall, gem heating furnaces play a crucial role in various aspects of the jewelry and gemstone industry, from enhancing the appearance of gemstones to supporting research, education, and quality control efforts.

Benefits of Gem Heating Furnace:

The benefits of a gem heating furnace, include:

Enhanced Gemstone Appearance

Heat treatment can significantly improve the color, clarity, and overall appearance of gemstones. By subjecting gemstones to controlled heating processes, imperfections can be minimized or eliminated, resulting in more visually appealing and valuable gemstones.

Versatility

Gem heating furnaces can accommodate a wide range of gemstone types and sizes, making them versatile tools for various applications within the jewelry and gemstone industry.

Precision Control

The furnace features intelligent temperature control with programmable segments, allowing precise control over the heating process. This precision ensures consistent results and allows for customization based on specific gemstone requirements.

Efficiency

The furnace is designed for energy efficiency, utilizing ceramic fiber insulation and high-purity heating elements to optimize heating performance while minimizing power consumption.

Safety

Safety features such as built-in protection against overheating, broken thermal couples, and leakage alarms ensure safe operation, protecting both the operator and the equipment.

Ease of Operation

The furnace is equipped with an intuitive touch screen interface, making it easy to operate and monitor the heating process. Additionally, the ability to store temperature curves streamlines workflow and reduces the need for manual adjustments.

Reliability

Constructed with high-quality materials and advanced technology, the furnace offers long-term reliability and durability, backed by a warranty and lifetime support.

Cost-Effectiveness

By efficiently enhancing the appearance of gemstones and minimizing waste, the furnace can contribute to cost savings for jewelry manufacturers and gemstone processors in the long run.

Research and Development

Gem heating furnaces support research and development efforts within the gemstone industry, enabling experimentation with different heating techniques and contributing to advancements in gemstone treatment methods.

Educational Value

The furnace serves as a valuable educational tool for students and professionals in gemology, providing hands-on experience with heat treatment processes and enhancing understanding of gemstone behavior.

Overall, the gem heating furnace offers a range of benefits, including improved gemstone quality, versatility, precision control, efficiency, safety, reliability, and cost-effectiveness, making it an essential tool for gemstone processing, manufacturing, research, and education.