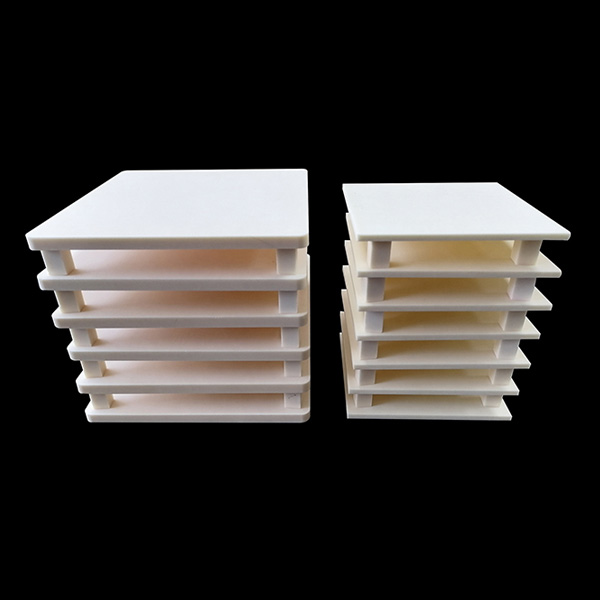

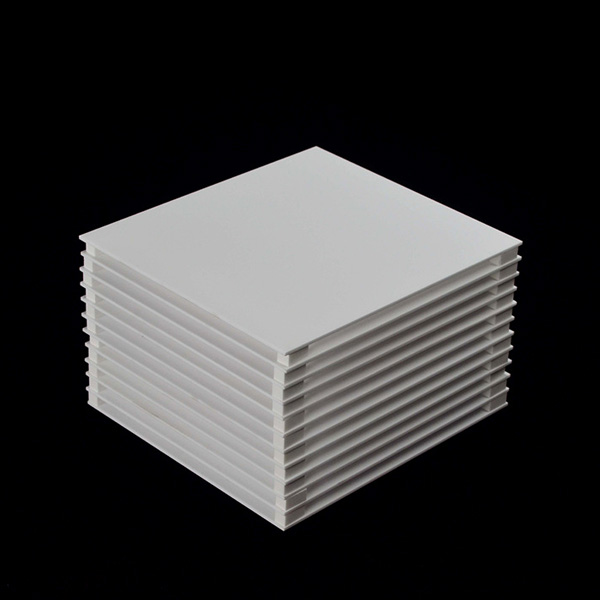

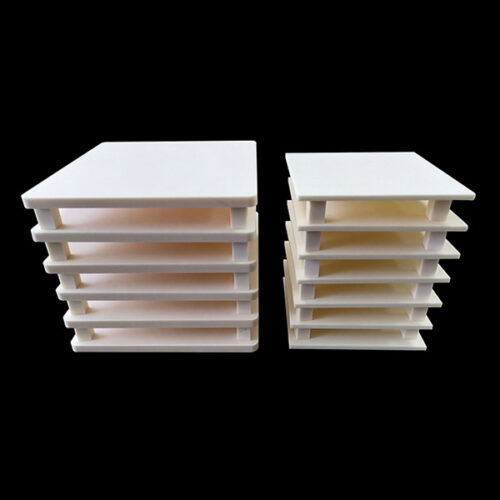

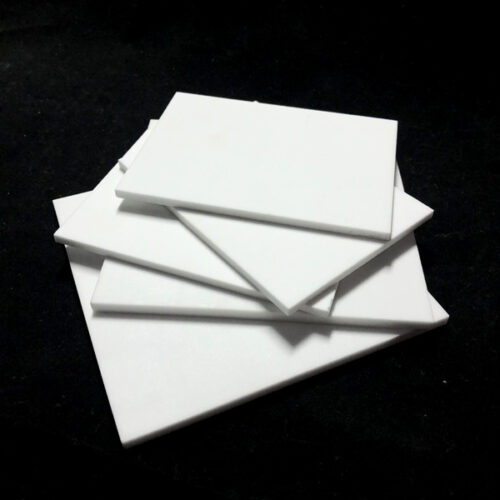

Advanced Alumina Furnace Furniture for Ceramics

Introduction:

Furnace furniture for ceramic refers to the components or accessories used inside a furnace to support, hold, or contain the materials being processed or treated. These components are typically made of ceramic materials due to their ability to withstand high temperatures and chemical reactions.

Common types of ceramic furnace furniture include trays, supports, shelves, setters, posts, rods, and crucibles. They play a crucial role in various high-temperature processes such as firing, sintering, annealing, and heat treatment in industries like ceramics, metallurgy, glass manufacturing, and semiconductor fabrication.

Advantages of furnace furniture for ceramics:

1. The material of the product is 99% alumina (Al2O3 > 99%).

2. Adopting slip casting/pressure molding technology.

3. Firing temperature is 1800°C, long-term use temperature ≤1600°C.

4. High temperature resistance and chemical corrosion resistance.

Functions of furnace furniture for ceramics:

Supporting and positioning materials:

Provides a platform for supporting and positioning the materials or samples to be processed.

Conducting heat:

Acts as a medium for heat conduction, helping to transfer heat from the heat source to the materials being processed.

Preventing contamination:

Made of high-purity materials, it does not contaminate the materials being processed.

Preventing adhesion and deformation:

The surface of ceramic furnace furniture is usually specially treated to prevent adhesion or deformation of the materials being processed at high temperatures, thus protecting the surface quality and shape of the materials.

Improving processing efficiency:

Through rational layout and design, ceramic furnace furniture can process multiple samples simultaneously or increase processing speed.

Specifications:

99 Alumina Ceramic Plate Specification Table (UoM:mm)

| 20×20×1.5 | 45×23×3 | 150×25×3 | 50×30×3 |

| 50×40×3 | 50×50×3 | 60×30×3 | 60×40×3 |

| 60×50×3 | 60×60×3 | 65×65×3 | 70×70×3 |

| 75×75×4 | 80×40×4 | 80×80×4 | 84×75×8 |

| 85×85×4 | 90×60×3 | 90×90×4 | 100×30×3 |

| 100×40×3 | 100×40×6 | 100×40×9 | 100×50×3 |

| 100×50×9 | 100×60×3 | 100×100×3.5 | 100×100×5 |

| 100×100×7 | 100×100×8 | 105×105×4 | 110×110×4 |

| 115×55×3 | 115×65×4 | 115×115×4 | 120×80×5 |

| 120×120×6 | 130×130×6 | 140×140×6 | 150×130×7 |

| 150×150×6 | 150×150×7 | 155×40×4 | 160×120×5 |

| 160×140×5 | 160×160×6 | 180×180×6 | 200×100×6 |

| 200×150×5 | 200×200×8 | 220×220×8 | 250×155×9 |

| 250×250×7 | 160×140×9 | 320×320×6 | 330×330×15 |

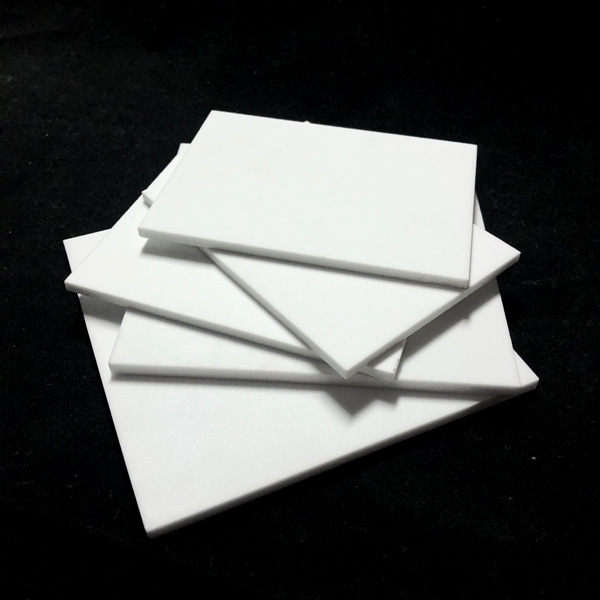

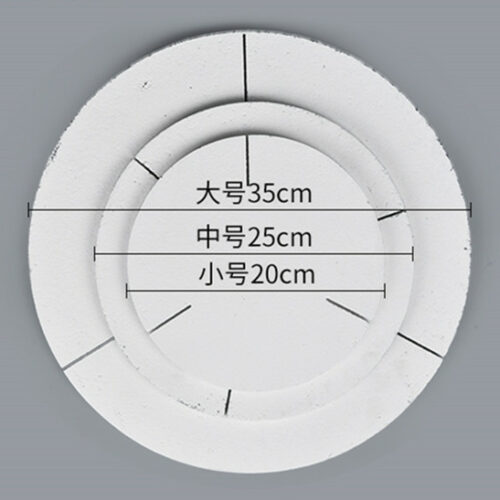

95 Alumina Ceramic Plate Specification Table (UoM:mm)

| 10×10×1 | 100×100×4 | 100×100×10 | 115×70×10 |

| 130×32×10 | 133×133×6 | 135×30×10 | 135×30×10 |

| 135×135×5 | 140×85×10 | 150×100×10 | 150×140×8 |

| 150×150×6 | 150×150×8 | 150×150×10 | 160×160×8 |

| 250×250×10 | φ20×2 | φ40×3 | φ45×4 |

| φ70×5 | φ100×5 | φ105×7 |

99 Alumina Standoff Specification Table (UoM:mm)

| Square Type | |||

| 4*4*4 | 4*4*6 | 4*4*7 | 5*5*3 |

| 5*5*4 | 5*5*5 | 5*5*7.5 | 15*10*8 |

| 15*10*10 | 19*9*6 | 20*15*12 | 20*20*20 |

| Cylinder Type | |||

| Ф8*6 | Ф18*15 | Ф30*20 | Ф35*13 |

| Ф35*20 | |||

Related Furnaces:

Related Furnace Furniture:

Precautions for using ceramic furnace furniture:

1. Ceramic furnace furniture is typically fragile, so handle with care to avoid collision or dropping, thus preventing damage.

2. Pay attention to controlling the temperature changes inside the furnace, avoiding sudden fluctuations to prevent the furnace furniture from fracturing or stress accumulation.

3. Regularly clean the surface of the furnace furniture to ensure it remains in good working condition, thus extending its service life.

4. Users often utilize ceramic furnace furniture for processing materials requiring high purity, so they should avoid contact with other impurities or chemicals to prevent material contamination.

5. When not in use, store the furnace furniture properly to prevent exposure to moisture, heat, or other environmental factors.

6. Select suitable ceramic furnace furniture according to the specific processing techniques and requirements to ensure it meets the demands of the process.