12L 1200 Celsius Furnace for Analysis

Introduction:

This 1200 Celsius Furnace for Analysis, is mainly used for chemical laboratories.

Engineers’ ingenious flat design not only greatly enhance the proportion of space, but also fit most people’s operating habits. Separate heating system and control unit can’t interfere with each other, this can ensure that the electric components and the entire circuit system to maintain a safe and reliable working condition in a sustained high temperature environment. At the same of strict control product quality, we pay more attention to customers’ experience to make the operation easier.

Features and Benefits:

1. Max. Temperature 1200.C, working temperature RT-1100.C.

2. Intelligent 7” color touch screen temperature controller, easy to operate, clear heating process; can store temperature curve to avoid the trouble caused by repeated settings of different experimental processes.

3. 30 segments programmable and auto control.

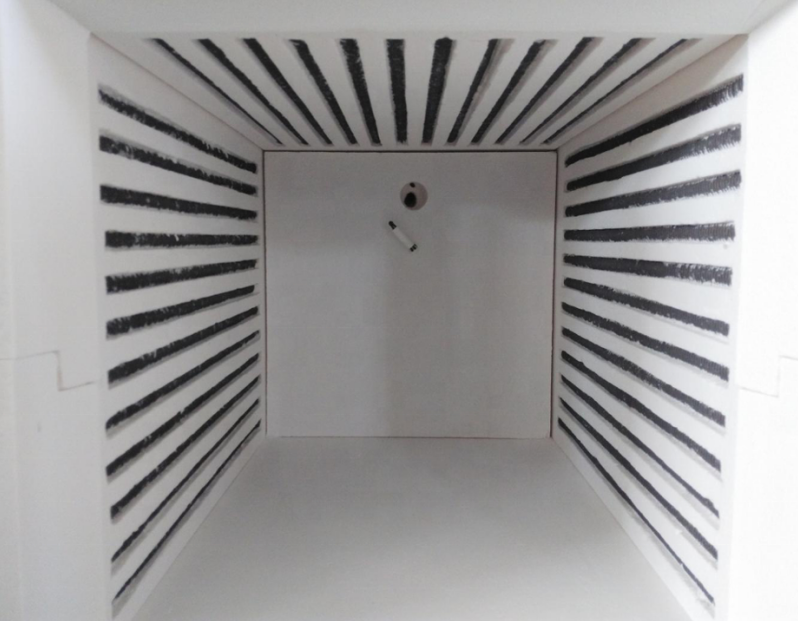

4. Ceramic fibre furnace chamber, to ensure a fast heating rate, and save power.

5. By using special lining import from Japan and high quality alloy heating wire with excellent acid and corrosion resistance, protected against chemical contamination at the best and longer service life.

6. Vent hole carefully designed is the perfect solution to the waste gas during material sintering.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

8. Low power consumable, exquisite structure and light weight, it is the ideal electric furnace for material research labs, also used in factory production.

Technical Specifications:

| Model | M1200-20IT

|

|

Furnace structure |

•1430 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

200*200*300mm |

| Max. temperature | 1200 ℃(<1 hours) |

| Working temperature | Rt -1100 ℃(continue) |

| Intelligent Touch Screen Temperature controller |

|

| Furnace Lining | Special top quality lining, will not pollute the product |

| Heating element | Top quality resistance wire |

| Heating rate | 0~20℃/min |

| Temperature accuracy | +/- 1 ℃ |

| Thermocouple | K type |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) |

| Max. Power | 4 Kw |

| Dimension | 650(W)*520(H)*600(D)mm

|

| Quantity / Net weight | 1set / 60kgs |

| Warranty | One year, lifetime support(not including consumable parts, such as heating elements, thermocouple) |

| Certificate | CE, ISO9001 |

Which kinds of industry can use this Programmable Muffle Furnace?

Universities, Chemistry, Medicine, Building Materials, Coal Mining, Metallurgy, Electronics,etc.

Applications:

Used in university laboratories, research institutes, and industrial and mining enterprise laboratories for sintering of metal ceramic materials, heat treatment of small steel parts, and quality testing.

For heat working or treatment of small workpieces in cement and building materials industries.

In the pharmaceutical industry for drug inspection, pre-treatment of medical samples,etc.

In analytical chemistry industry, mainly used for sample treatment in water qualiy analysis, environmental analysis and other fields. It can also be used for oil and its analysis, soil composition and grain analysis.

Used in the coal mining industry for measuring moisture, ash, volatile matter, ash melting point analysis, ash composition analysis, and elemental analysis. It can also be used as a universal ashing furnace.