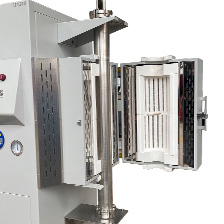

Lab-Scale Fluidized Bed Sintering Furnace for Uniform Heating and Precise Gas Control

Introduction

The Fluidized Bed Sintering Furnace is a high-performance heat treatment device, particularly suitable for material synthesis, heat treatment, and sample preparation under controlled atmospheres at high temperatures. This equipment combines the advantages of fluidized bed technology and tube furnaces, enabling uniform heating and efficient reactions in high-purity atmospheric conditions.

Key Features

- Working Temperature: The maximum working temperature can reach up to 1200°C, making it suitable for the synthesis and treatment of various high-temperature materials.

- Fluidized Bed Technology: The fluidized bed design allows solid particles to suspend and remain in motion under the action of gas flow, ensuring even heating of the samples. It is ideal for processing powdery or fine granular materials, such as catalysts and nanomaterials.

- Tube Structure: The vertical tube structure design makes loading and unloading samples easier, saves space, and is suitable for laboratory environments. The internal tubing is typically made of high-temperature alloy materials (optional high-purity quartz tube), providing excellent corrosion resistance and thermal stability.

- Temperature Control: Equipped with an advanced PID temperature control system that supports multi-stage program control, ensuring high precision and repeatability in temperature control. Real-time monitoring and adjustment of the furnace temperature are available.

- Atmosphere Control: Supports multiple atmospheric environments, including vacuum, inert gases (such as nitrogen, argon), and reducing gases, to meet various experimental needs. The gas control system allows precise control of gas flow and ratios.

- Ease of Operation: The system features a touch screen control interface that supports data recording and remote monitoring for easy operation and process monitoring. Multiple experimental programs can be set and saved for repeated use.

- Safety Design: Includes built-in over-temperature protection, overcurrent protection, and other safety features to ensure safe operation. It also has an emergency shutdown function, allowing the power to be cut off quickly in case of abnormal conditions.

- Efficient Cooling: The furnace is equipped with a high-efficiency cooling system, supporting rapid cooling to improve production efficiency. Optional water-cooling or air-cooling systems are available, allowing for the selection of the most suitable cooling method based on specific needs.

Technical Specifications

| Equipment Name | Fluidized Bed Sintering Furnace |

| Model | FB1200-80 |

| Max.temp | 1200°C |

| Rated Temperature | 1150°C |

| Power Supply | 220V 50/60HZ(or as requirement) |

| Rated Power | 4.0 KW |

| Furnace Tube Size | φ80*1000mm(φ70*2 porous plate) |

| Furnace Chamber Space | φ150×430mm |

| Heating Rate | 1°C/H-20°C/Min |

| Furnace Dimensions | L1100*H1800*D670mm |

| Intelligent Touch Screen Control System | 1. Can store up to 15 temperature profiles, avoiding the trouble of repeatedly setting different experimental processes.

2. More intuitive experiment process, easier operation. 3. Embedded operating system with Chinese and English graphic interface, 7-inch true color touchscreen input, intelligent human-machine dialog mode, and non-linear temperature correction. 4. Includes over-temperature alarm, thermocouple disconnection alert, leakage protection, and other safety functions.

|

| Temperature Accuracy | ±1°C |

| Heating Elements | High-temperature alloy wire |

| Equipment Features | Solid particles are suspended and kept in motion under the action of gas flow, ensuring uniform heating of samples.

|

| Net Weight | 220kg |

| Service Support | One-year limited warranty with lifetime support (the warranty does not cover consumable parts such as processing tubes and O-rings; please order replacement parts from the relevant product section below). |

Applications of Fluidized Bed Sintering Furnace

- Material Synthesis: Ideal for synthesizing ceramics, metals, and composites at high temperatures.

- Powder and Nanomaterial Treatment: Efficient for processing fine powders and nanomaterials like catalysts.

- Heat Treatment: Used for sintering, calcination, and annealing of materials in controlled atmospheres.

- Catalyst Activation: Perfect for activating and regenerating catalysts in chemical industries.

- Metallurgical Processing: Suitable for alloy production and refinement.

- R&D: Commonly used in labs for material testing and process studies.

- Battery Material Production: Used in the preparation of electrode materials for batteries.

- Thermal Coating and Surface Treatment: Applied in thermal spraying and metal surface treatments.

For More Options on Sintering Furnaces

Please visit our website [Sintering Furnaces Collection]

For More Info on Fluidized Bed Technology

Please read our blog [Fluidized Bed Technology]