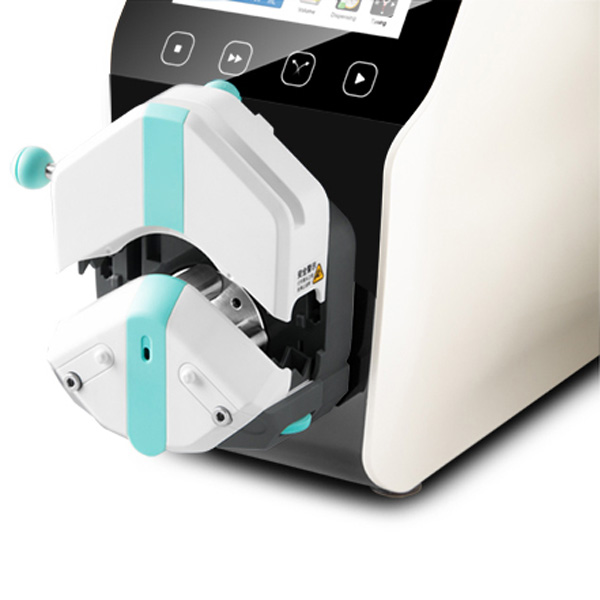

0.0053~775ml/min Lab Intelligent Flow Rate Peristaltic Pump

Introduction:

This intelligent flow rate peristaltic pump, with ABS Engineering plastic shell and add UV spray coating to have anti-corrosion and anti-static function. Streamlined body design, industrial grade 4.3” color display with touch screen control, speed range is 0.1~150rpm, flow rate range is 0.0053~775ml/min; support RS232 and RS485 interface, standard MODBUS communication protocol. Achieve external control under different industrial conditions. It is the ideal choice for laboratory, instrument and industrial production. The rich external control mode has arbitrary choice, and has the unique programmable external control mode.

Main Features:

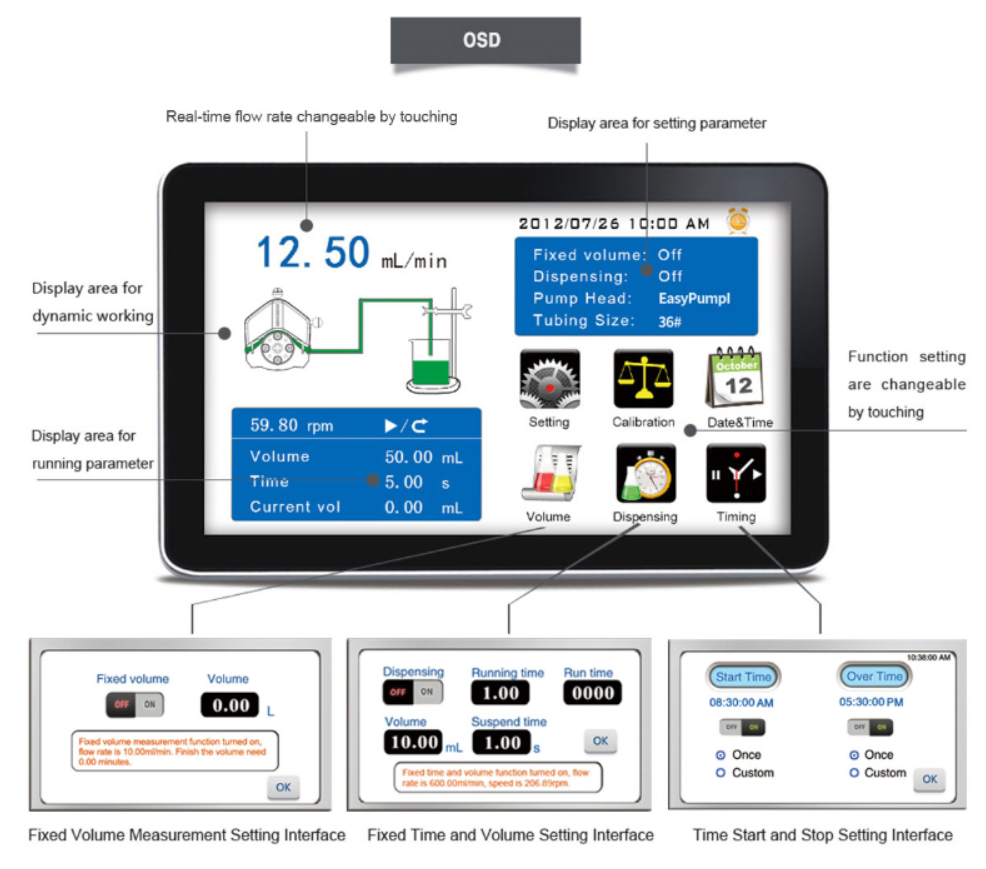

1. Industrial grade 4.3″ true color LCD screen, touch screen control.

2. Mechanical keypad control pump start, stop, full speed and direction.

3. Dynamic display transferring status. Flow rate data, setting parameters and system configuration display in the same screen.

4. 3 Kinds of working mode: fixed volume metering, fixed time and volume, timer start and stop, meet different transferring and

dispensing request.

5. Intelligent calibration function and online micro adjusting function.

Technical Specifications:

| Model | LabV1-III |

| Power | <80w |

| Motor | Closed-loop stepper motor |

| Flow Rate | 0.0053-775mL/min |

| Speed Range | 0.1-150rpm |

| Flow rate resolution | 0.01 ul |

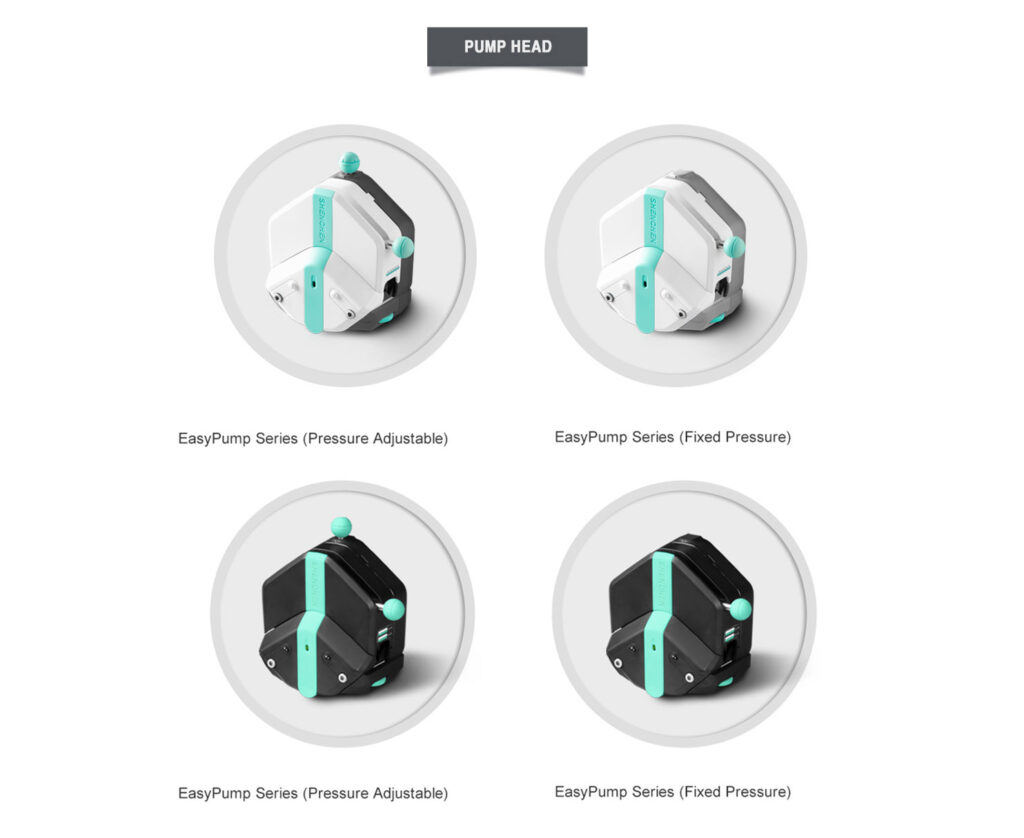

| Pump Head | Easy Pump |

| Channel | Single/Dual Channel |

| Display | 4.3 inch industrial grade true color LCD screen |

| Control Method | Touch screen and mechanical keypad |

| Housing | ABS engineering plastic shell |

| Power Supply | 220V +/-10% 50/60Hz(standard), 110V 60Hz(optional) |

| Dimension | 259x157x237(LxWxH)mm |

| Net Weight | 4.4kgs |

| Warranty | 3 years |

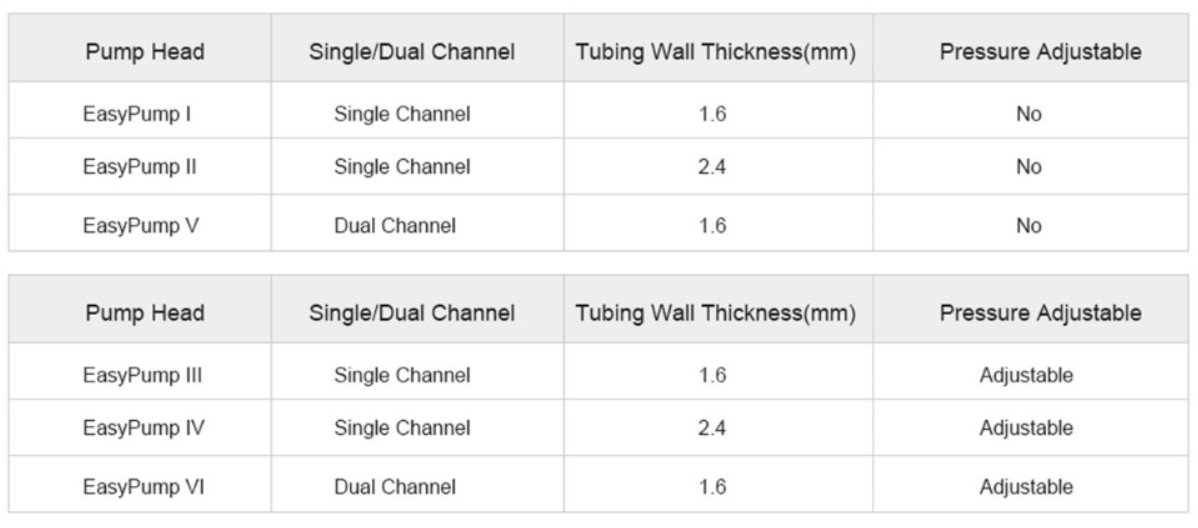

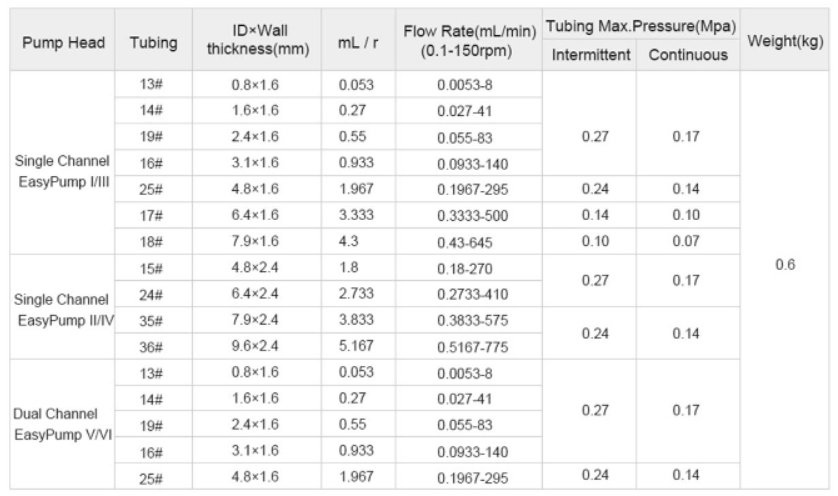

Pump Head & Flow Rate:

Applications:

This flow rate peristaltic pump, also known as peristaltic pump, is versatile device used in a variety of industries due to its ability to precisely control fluid flow. Here are some key applications:

- Laboratory and Research:

- Chemical Dosing: Precise delivery of reagents, solvents, or buffers in chemical analysis.

- Cell Culture: Pumping cell culture media, ensuring sterile and contamination-free environments.

- Pharmaceutical Research: Accurate dosing of pharmaceutical ingredients or drugs during formulation and testing.

- Water Treatment:

- Chemical Injection: Adding chlorine, acids, or other chemicals for water purification.

- Nutrient Dosing: Managing nutrient levels in aquaculture and hydroponic systems.

- Food and Beverage Industry:

- Flavor and Color Additives: Precise delivery of flavorings, colorings, or other additives in food and beverage production.

- Filling and Packaging: Dispensing liquids into containers in a hygienic and controlled manner.

- Industrial and Manufacturing:

- Ink and Dye Transfer: In printing processes, transferring inks, dyes, and other liquids without contamination.

- Adhesives and Sealants: Controlled dispensing of adhesives or sealants in production lines.

- Lubrication: Precise lubrication of machinery parts during operation.

- Environmental and Waste Management:

- Sample Collection: Collecting liquid samples from environmental sources for analysis.

- Wastewater Treatment: Metering chemicals for the treatment of wastewater.

- Pharmaceutical and Cosmetic Manufacturing:

- Creams and Gels: Accurate filling of tubes and containers with creams, lotions, or gels.

- Active Ingredient Dispensing: Delivering precise amounts of active ingredients into formulations.