Five-Temperature Zone CVD Furnace

Applications:

Chemical Vapor Deposition (CVD)

Synthesize coatings or nanomaterials

Depositing thin film materials

Synthesize insulating materials as well as most metal and metal alloy materials.

Fields:

Semiconductor industry

Materials laboratories

Universities

Research institutes

Environmental science and other fields

Introduction:

Chemical Vapor Deposition (CVD) refers to a method where chemical gases or vapors react on the surface of a substrate to synthesize coatings or nanomaterials. It is the most widely used technology in the semiconductor industry for depositing thin film materials, including a broad range of insulating materials as well as most metal and metal alloy materials. In response to this, we have developed a comprehensive CVD coating system suitable for materials laboratories in major universities, research institutes, environmental science, and other fields.

Five-Temperature Zone CVD Furnace consists of the following components:

- Sintering System;

- Electrical Control System;

- Top Cover Opening System;

- Vacuum System.

Main Features:

- Stable and reliable control, user-friendly operation.

- Utilizes advanced PID self-learning fuzzy control for high temperature control accuracy, maintaining within ±1℃.

- Furnace lining adopts high-purity alumina lightweight fiber material, providing superior insulation and energy efficiency.

- Data storage function, capable of retaining essential sintering parameters for up to 30 days (with 8 hours of operation per day).

- Formula management function, able to store and retrieve more than 100 pre-set formulas.

- Independent control of five temperature zones, allowing for a diverse and complex sintering process tailored to customer requirements.

- Networking capability through RJ45 interface, employing TCP/IP protocol for seamless connection to an upper-level system (requires installation of corresponding software on the upper-level system).

Technical Parameters:

| Model | T1200-100T5G4F | ||||

| Power supply | 380V 50HZ | ||||

| Rated power | 10KW | ||||

| Thermocouple | K type | ||||

| Max temperature | 1150.C | ||||

| Recommend Heating rate | 10.C/min | ||||

| Furnace heating chamber | Dia 150* 1135mm | ||||

| Tube size | Dia 100* 1600mm | ||||

| Temperature accuracy | +/- 1 ℃ | ||||

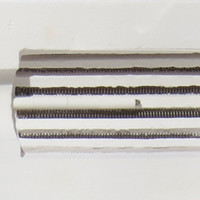

| Heating element |

Molybdenum-Doped Fe-Cr-Al Alloy High-Temperature Heating Wire |

||||

| Sealing System |  |

||||

| Vacuum level:≤10Pa(Mechanical Pump) | |||||

| Pressure Measurement and Monitoring | Utilizing a mechanical pressure gauge with shock-absorbing oil to introduce damping effects during pressure fluctuations, reducing the back-and-forth oscillation of the pointer. |  |

|||

| Control System |

|

|

|||

| Protection | Built in protection for over-heated and broken thermal couple, and leakage. | ||||

| Dimension | 1900(L) * 900(W) * 1250(H)mm | ||||

| Weight | 350KG | ||||

| Warranty | One-year warranty, lifetime support (excluding consumable parts such as furnace tubes, O-rings ) | ||||