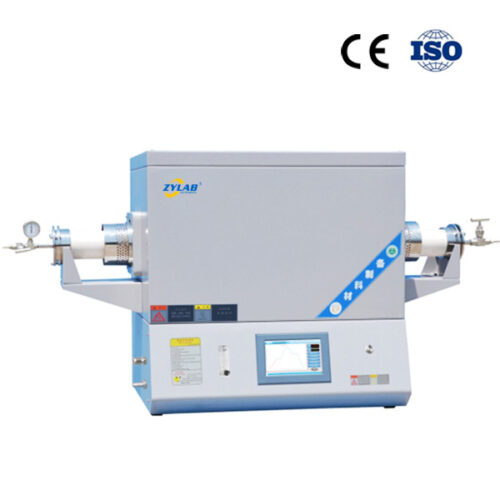

Intelligent Experimental Hydrogen Reduction Furnace

Introduction:

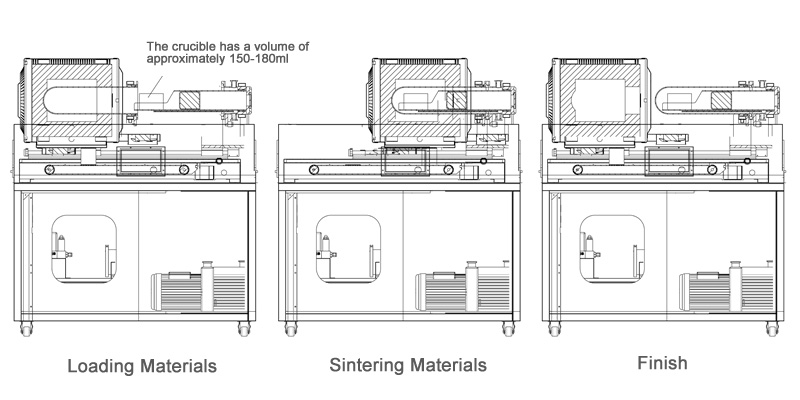

The Intelligent Experimental Hydrogen Reduction Furnace is a fully-featured, safe, and reliable laboratory equipment. It is suitable for various applications in industries such as metal heat treatment under reducing atmospheres, rare earth preparation, electronic lighting, crystal annealing, special alloys, magnetic materials, and precision casting. It is used for processes such as vacuum sintering, atmosphere-controlled sintering and reduction sintering, CVD experiments, material composition measurements, etc. The equipment is equipped with comprehensive safety measures for handling toxic, harmful, and flammable gases.

Features of Hydrogen Reduction Furnace:

- Automatic switching of gas types and flow rates.

- Automatic regulation of internal pressure under protective atmospheres.

- Automatic adjustment of vacuum level during vacuum sintering.

- Manual/automatic mode with adjustable process parameters.

- Automatic pipeline cleaning function.

- Automatic ignition of exhaust gas with dual-channel protection.

- Automatic overpressure protection and alarm functions.

- Comprehensive safety features for worry-free experimental production.

- Rapid cooling of the sample.

- Embedded operating system with interchangeable English and Chinese graphical interface, 7-inch full-color touchscreen input, intelligent human-machine dialogue mode, real-time display of heating power, nonlinear sample temperature correction; autonomous generation of experimental reports, unlimited export of experimental data.

Technical Parameters:

| Model | CMT1200-100TI

|

| Max.temp | 1200.C |

| Length of heating zone | 200mm |

| Uniform temperature space | Φ80*120 mm |

| Control system | Intelligent system |

| Process Menu Editing | User-friendly operation with graphical interface |

| Vacuum System | 4C Vacuum Pump + Solenoid Valve |

| Vacuum Pressure Measurement | Pirani Digital Vacuum Gauge with 485 communication |

| Gas Supply System | 2-channel Mass Flow Controllers

485 communication |

| Ignition System | Dual Automatic Ignition |

| Functional Implementation | Manual/Automatic Switching |

| Process Control Mode | Intelligent Fuzzy Closed-Loop PID Control |

| Power | 4 kw |

Applications:

This intelligent Experimental Hydrogen Reduction Furnace is suitable for various applications in industries such as metal heat treatment under reducing atmospheres, rare earth preparation, electronic lighting, crystal annealing, special alloys, magnetic materials, and precision casting. It is used for processes such as vacuum sintering, atmosphere-controlled sintering and reduction sintering, CVD experiments, material composition measurements, etc.