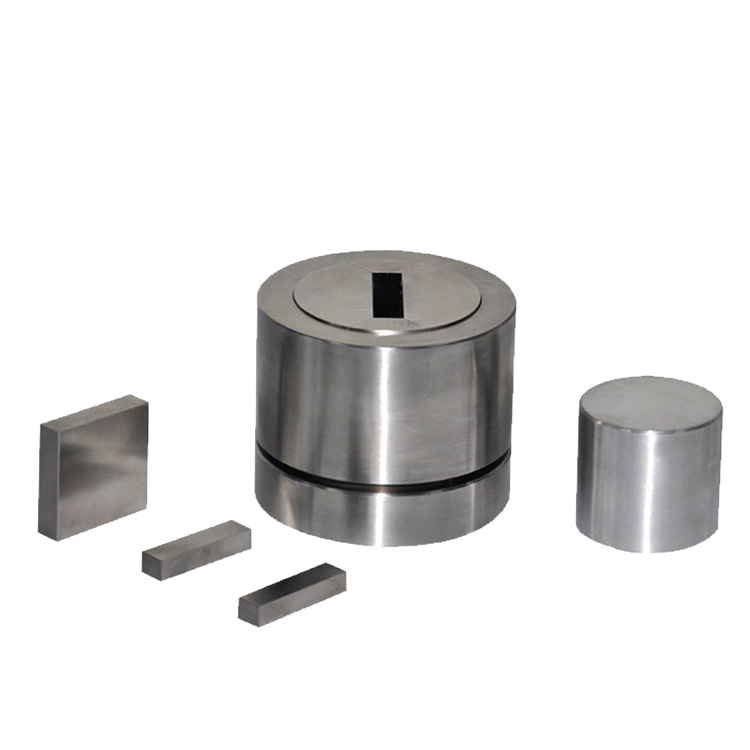

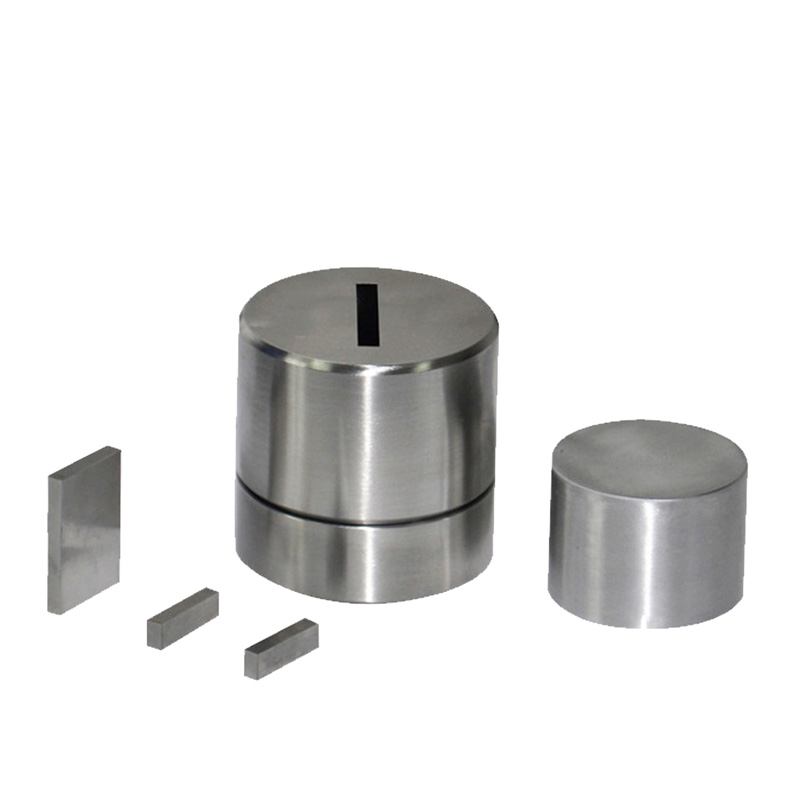

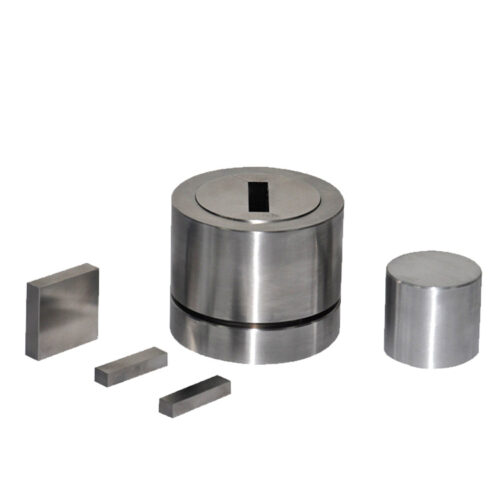

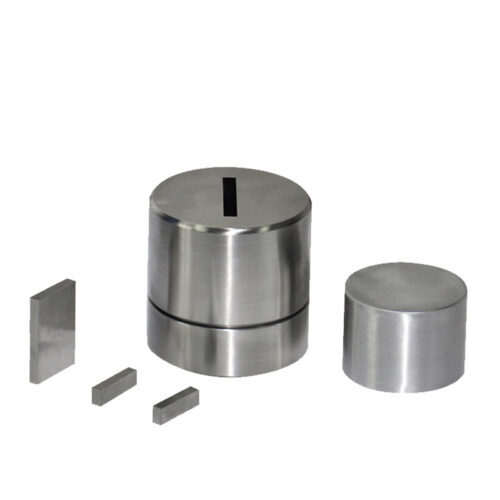

Dry Pellet Pressing Die Set for Lab Use

Introduction

The Dry Pellet Pressing Die Set for Lab Use is designed for high-precision powder compaction and pelletizing in laboratory environments. Ideal for research and material testing, this die set allows for the creation of uniform pellets from dry powder samples. It is commonly used in powder metallurgy, material science, and chemical analysis, where consistent pellet formation is crucial for accurate testing and analysis.

Types and Specifications

The Cylindrical Die

The cylindrical die can be used for the molding and testing of most powder samples, commonly employed in experiments within various fields such as ceramics, cement, batteries, new materials, catalysis, and pharmaceuticals for laboratory infrared analysis, spectral experiments, and more.

The Cylindrical Split Die

The cylindrical split die, also known as an easily removable modular mold, is a commonly used tablet compression mold in laboratories. It typically consists of three internal cores combined to form a cylindrical cavity, with the diameter of this cavity representing the size of the pressed powder sample. The three internal cores are secured as a single unit by placing a circular sleeve around them. After compression, the mold can be quickly disassembled by removing the sleeve, separating the three internal cores. The powdered sample can then be directly collected without the need for a demolding process, avoiding the risk of sample fracture or damage during demolding.

Split die are mainly used for pressing powder samples that are difficult to form or demold. When used with a tablet press, they can be utilized to press various powder materials, such as potassium bromide (KBr), sodium chloride (NaCl), silicon dioxide (SiO₂), aluminum oxide (Al₂O₃), zirconium oxide (ZrO2), etc., to create circular samples, cylinders, or other shapes for scientific analysis and research. They are widely applied in research, teaching, catalysis, testing, pharmaceuticals, chemical engineering, and the development of new materials.

Selection Guide:

Cylindrical split die with easy demolding belong to laboratory consumables, typically comprising a die base, die cores (three petals), die sleeve, die pressure rod, die spacer, and demolding sleeve. They can be customized in various specifications, with a delivery time ranging from 3 to 20 days. Common die sizes range from Φ3 to Φ40mm, with specifications including Φ3, Φ5, Φ6, Φ7, Φ8, Φ10, Φ12, Φ12.7, Φ13, Φ15, Φ18, Φ20, Φ25, Φ30, Φ32, Φ35, Φ40, Φ100mm, etc.

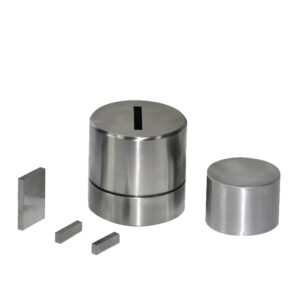

Regular Square Die

The regular square die is commonly found in laboratories for compressing powder materials and preparing rectangular, square, triangular, or other-shaped thin slices, cylinders, etc. It needs to be used with a tablet press and is capable of pressing various powder materials such as potassium bromide (KBr), sodium chloride (NaCl), silicon dioxide (SiO₂), zirconium oxide (ZrO2), aluminum oxide (Al₂O₃), and others into solid shapes for research. It has been widely applied in various fields, including research, teaching, catalysis, testing, pharmaceuticals, chemical engineering, and the development of new materials.

Selection Guide: The commonly used specifications for regular square die generally have dimensions within 3-50mm, with popular sizes including 5×10mm, 10×10mm, 10×20mm, 10×30mm, 20×20mm, 30×30mm, 40×40mm, 50×50mm, etc. Square molds are considered laboratory consumables, and customizations for various dimensions can be non-standard, with a typical delivery time ranging from 3 to 20 days.

Rectangular Split Die

The rectangular split mold is suitable for compressing slender samples that are not easily molded. The mold addresses the issue of sample deformation during demolding by quickly disassembling the outer casing, ensuring the molding of the sample. The mold pressing width ranges from 3 to 100mm. Special die sizes can be customized according to customer requirements. The die is made of CR12 mold steel and has four petals in the internal core.

Hard Alloy Die

Hard alloy die, also referred to as tungsten steel molds or tungsten carbide molds, come in cylindrical and rectangular shapes. These molds are custom-made products, and production can commence upon customer orders. Various specifications and models of hard alloy molds can be tailored to meet customer requirements. Due to the higher cost involved, commonly used specifications generally do not exceed 40mm. Hard alloy, known for its high hardness and wear resistance, is an essential choice for the pressure molding of hard metal powders.

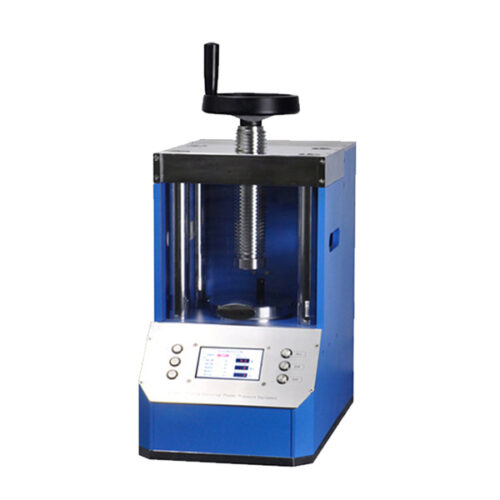

Die Operation Steps

- Assemble the mold according to the mold operation diagram and load the sample into the cavity.

- Place the mold at the center position of the tablet press and apply pressure to the desired level for the sample.

- Remove the mold from the tablet press, take off the mold base following the demolding diagram, attach the demolding sleeve, and position it at the center of the tablet press.

- Gently rotate the handwheel of the tablet press, use the screw to push the sample out of the mold sleeve.

- Remove the mold from the tablet press and gently take out the sample.