GR-10CE 10L Double-wall Glass Reactor

Introduction:

Double-wall glass reactor, also known as a jacketed glass reactor, is a type of laboratory equipment used for chemical reactions and other processes in the field of chemistry and research. It is a versatile tool that allows scientists and researchers to carry out reactions under controlled conditions.

This Double-wall Glass Reactor is mainly used for synthetic reaction, distillation and concentration of different types of materials.

Main Features and Advantage:

●High borosilicate glass 3.3 has good physical and chemical properties.

●Wide working temperature range: -80~200℃.

●Working pressure: -0.1 MPa to 0.0 MPa.

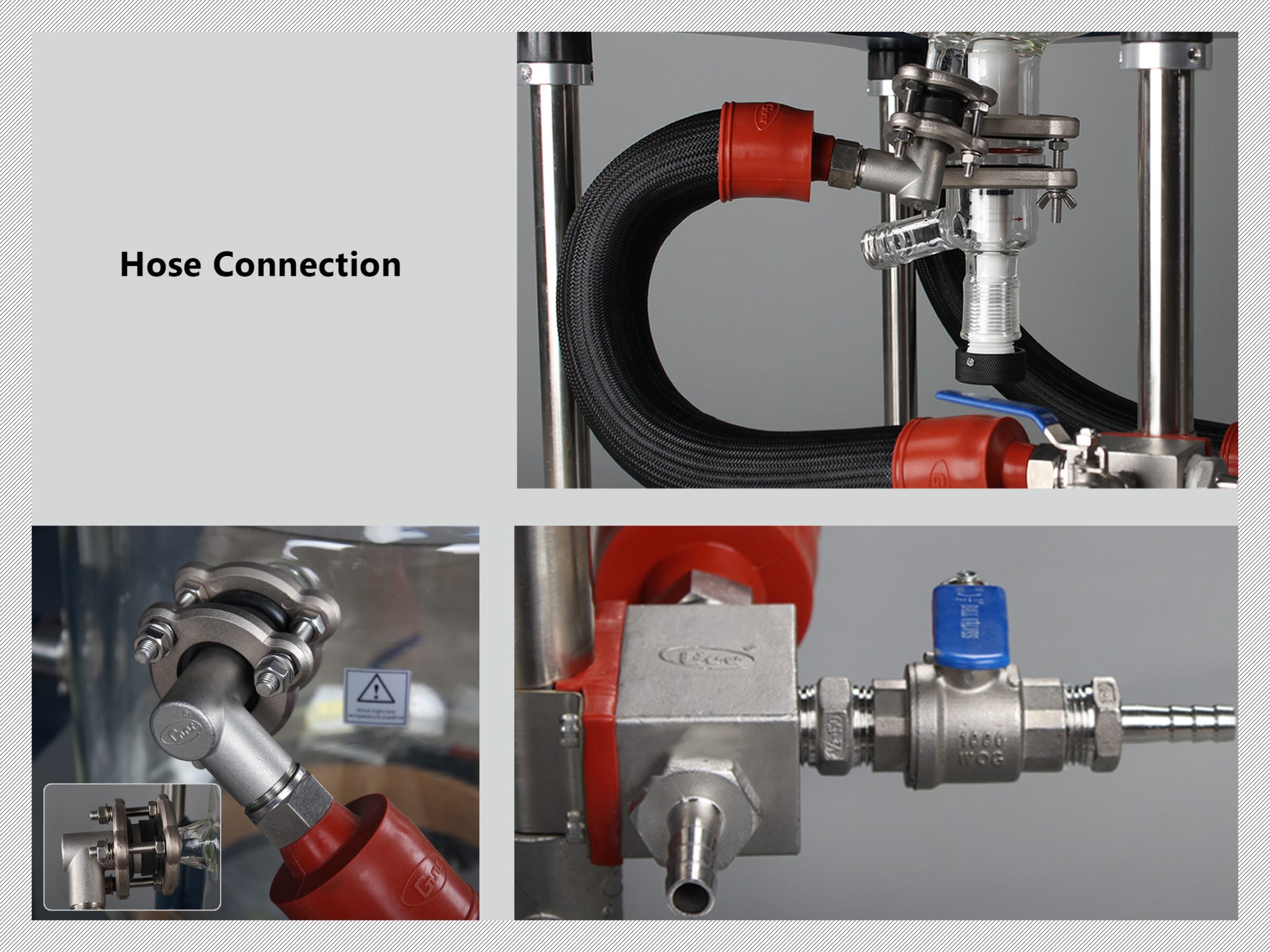

●Stainless steel hose connected to the jacket inlet/outlet.

●PTFE discharge valve.

●Stainless steel frame, corrosion resistant.

●SUS304 material tray (Optional).

●Low-pressure brushless DC motor, stepless speed regulation, long-life span, high efficiency, low maintenance.

●Intelligent controller and monitor, LED digital display of torque, temperature, time and rotation speed, easy to operate.

●RS485 communication interface on the control box can transfer the data to PC.

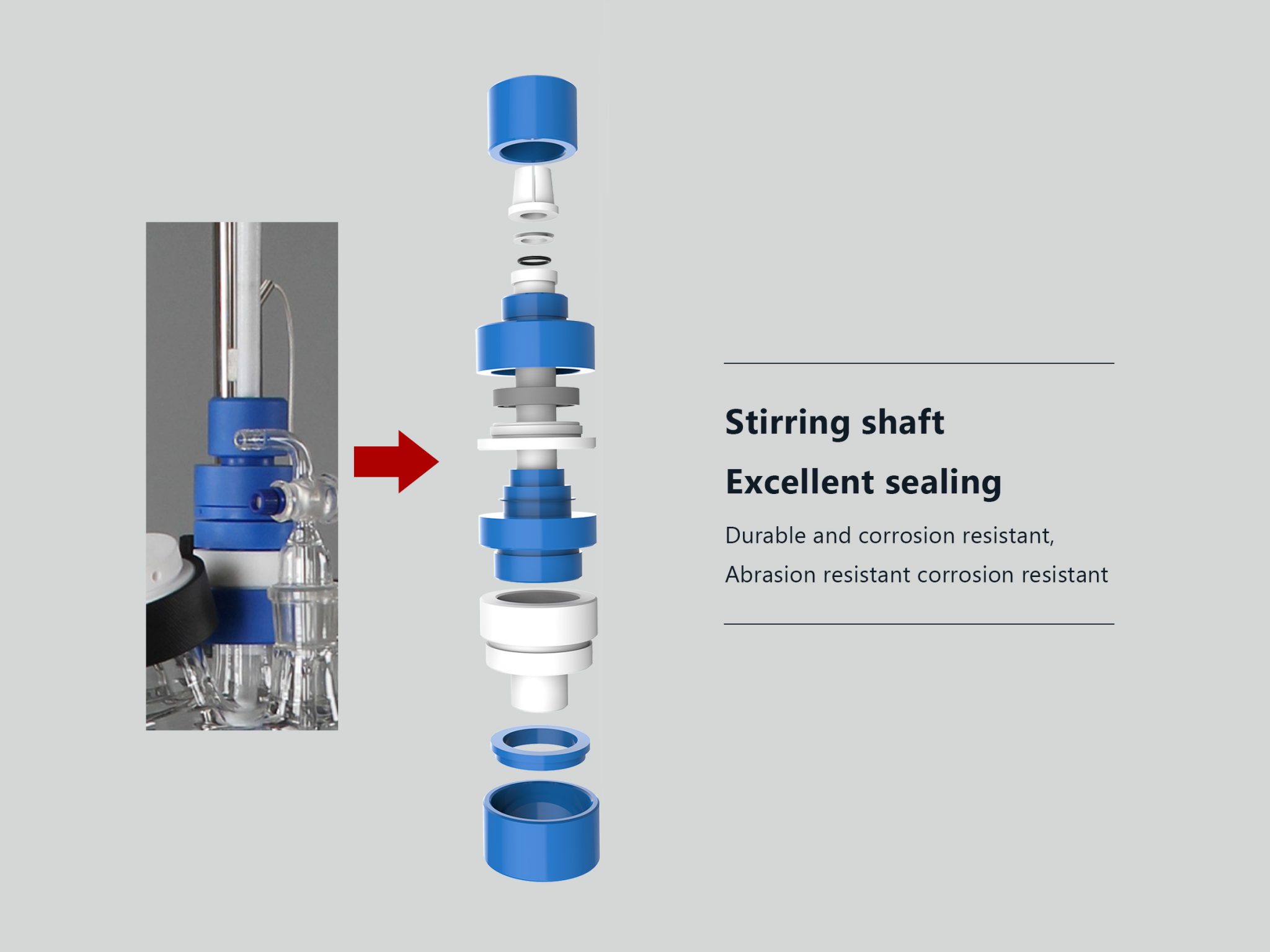

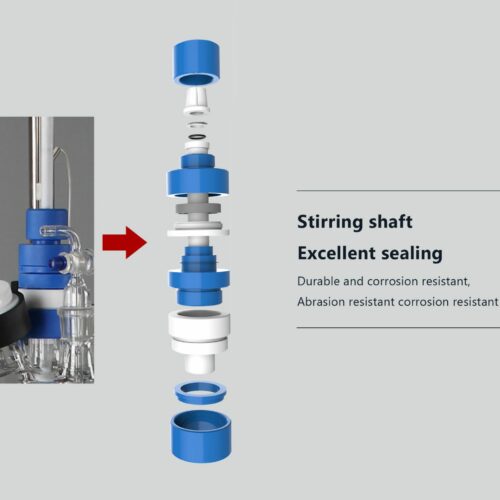

●Patented stirring shaft has high sealing efficient and long lift-span.

●PT100 temperature sensor has high control accuracy, SUS304 coated with PTFE tube, double anti-corrosion.

●PTFE stirring paddle, SUS304 coated with PTFE.

Specifications of 10L Double-wall Glass Reactor:

| Model | GR-10/GR-10CE |

| Vessel volume | 10.0L |

| Pressure in the vessel | -0.1-0.0MPa |

| Pressure in the jacket | ≤0.03MPa |

| Working temperature range | -80-200℃ |

| Condenser exchanging area | 0.234 m² |

| Vessel inlet/outlet | DN15 |

| Constant-pressure funnel volume | 1.0L |

| Display window | LED |

| Stirring speed | 20-500rpm |

| Stirring speed display accuracy | ±1rpm |

| Speed regulation accuracy | Speed<=300r/min:±0.7% |

| Speed>300r/min:±1% | |

| Max. torque | 5.4N.m |

| Motor power | 370W |

| Power supply | 100-240V~,50/60Hz |

| Fuse | TSD 6.3A L (For 100-120V~) |

| TSD 5A L (For 220-240V~) | |

| Ambient temperature | 5-35℃ |

| Relative humidity | <=65% |

| Protection grade of shell | IP20 |

| Anti-pollution grade | 2 |

| Sea level | <=2000m |

| Discharge height | 320mm |

| Dimensions | 845W*640D*1780H mm |

| Net weight | 48kgs |

| Warranty | 12 months, lifetime support |

| Certificate | CE, ISO9001 |

| Package information | 195*70*82cm, 114kgs |

Optional Turnkey Solution:

Vacuum Pump

Temperature Control Unit

Which kinds of industry use this Double-wall Glass Reactor?

Applications of Double-wall Glass Reactor:

Double-wall glass reactors have a wide range of applications in chemistry and research.

They are used for chemical synthesis, crystallization, distillation, extraction, mixing, homogenization, photochemical reactions, solvothermal reactions, material synthesis, pharmaceutical research, and academic studies. They are also used for scale-up studies before moving to larger industrial-scale reactors.

Benefits of Double-wall Glass Reactor:

1. Controlled reaction conditions.

2. Visual observation of reactions.

3. Safety due to the double-wall construction.

4. Versatility for various applications.

5. Scalability for process development.

6. Easy cleaning and maintenance.

7. Efficient heat transfer.

8. Corrosion resistance.

9. Cost-effectiveness.

10. Support for research and development efforts.

Click to See More Content:

Overview of Laboratory Glass Reactors

PTFE Spray Cleaning Inside of Reaction Vessel

Laboratory Glass Reactor Feeding Pump

For More Options on Glass Reactors

Click here [Glass Reactors Collection]

For Solutions on Chemical Synthesis

Click here [Chemical Synthesis Solutions Collection]