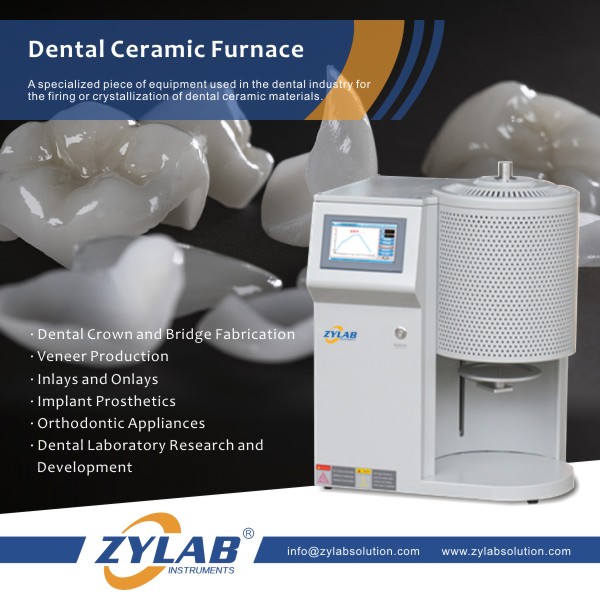

Reliable Dental Ceramic Furnace for Efficient Firing of Dental Materials

Introduction

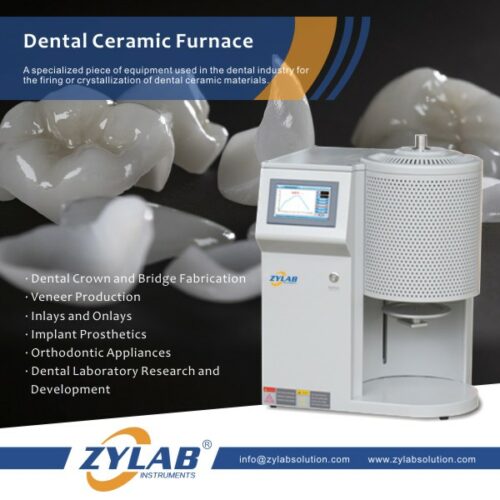

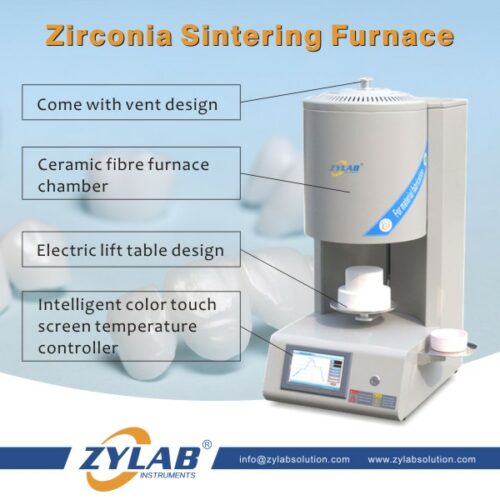

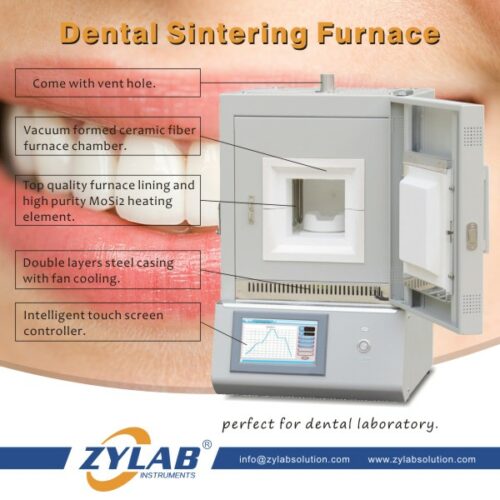

ZYLAB Dental Ceramic Furnace as our company’s newly launched sintering equipment, fully draws on the advantages of previous dental sintering equipment, and optimizes part of the design scheme. It is ideal desktop intelligent denture material sintering equipment.

It use special high-purity and high-density silicon carbon rod heating element, the maximum working temperature is 1550 ℃, and the annular cleaning heating process ensures a high temperature uniformity of the denture heating environment. And it is easy to operate by lifting and loading materials down.

Moreover, the control system adopts an intelligent human-computer interaction touch-screen control system. The touch-screen visual guide operation can quickly set the heating curve, support curve storage and recall, and can enter the working state in 5 minutes, display the sintering dynamic power and sintering process in real time.

Key Features

- High-Purity Furnace Chamber: Made with durable polycrystalline fiber for excellent thermal insulation.

- Modular Structure: Easy to maintain and built to last.

- Precision Temperature Control: Advanced PID self-learning fuzzy control ensures accuracy within ±1°C.

- Efficient Vent Design: Top vent eliminates drying and pre-burning volatiles.

- User-Friendly Touchscreen: Easy-to-use interface with storage for up to 15 working curves.

- Real-Time Monitoring: Tracks sintering temperature and power usage for safety and energy efficiency.

- Multiple Safety Protections: Includes over-temperature alarm, broken couple prompt, and leakage protection.

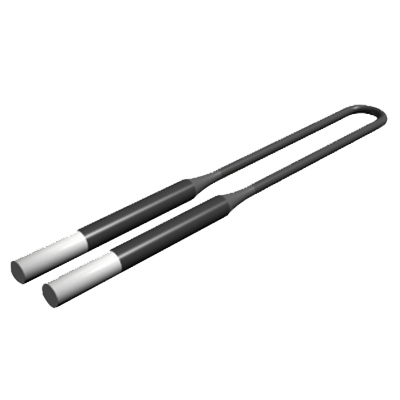

- High-Density Silicon Carbide Heating Elements: Ensures uniform temperature distribution and stable performance without secondary pollution.

- Improved Temperature Uniformity: Four-sided annular heating provides consistent firing, ensuring better crown permeability and consistency.

- Space-Saving Design: Compact with large capacity—can fire 30~50 pieces per cycle, boosting production efficiency. (size 100*32mm crucible can be stacked in two layers)

This furnace combines advanced technology with a user-friendly design, making it the ideal choice for professional dental laboratories.

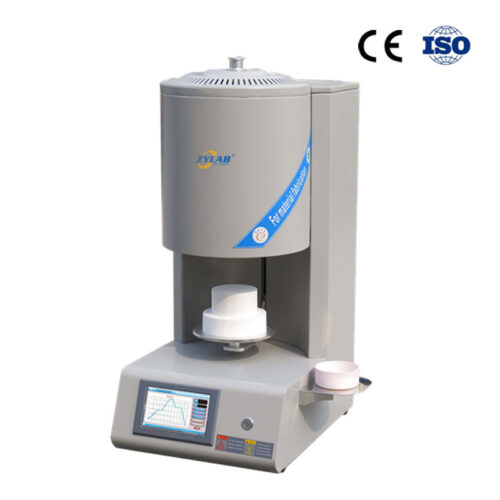

Technical Parameters of Dental Ceramic Furnace

| Model | B1600-12TI |

|

Furnace Structure |

1. Advanced alumina fiber thermal insulation refractory as chamber material; 2. Cylindrical chamber shape, annular heating; 3. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C.. |

| Chamber Mode | Auto Lifting |

| Chamber size

(working space) |

Ø120x150mm (Diameter x Height) |

| Max. temperature | 1550 ℃(<1 hours) |

| Intelligent Touch Screen

Temperature Controller |

1. PID automatic control and auto-tune function. 2. 30 programmable segments for precise control. 3. Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. 4. Real-time monitoring, dynamic real display “time-temperature curve”.

|

| Heating rate | 0-20.C /min |

| Thermocouple | Double platinum rhodium type B thermocouple |

| Temperature accuracy | +/- 1 ℃ |

| Heating element | Special high-density and high-purity silicon carbide rods (5 pieces)

|

| Working voltage | AC208-240V 50/60HZ (according to requirement) |

| Max. Power | 2Kw |

| Dimension | 580(L)*740(H)*490(D)mm |

| Quantity / Net weight | 1set /60kgs |

| Warranty | 12 months(not including consumable parts, such as heating elements), lifetime support. |

| Accessories come with furnace | 1 set bottom bracket ; 1pc crucible tong; 1 pc instruction manual. |

Applications of Dental Ceramic Furnace

Dental ceramic furnaces have several applications in the field of dentistry. Here are some common uses:

1. Dental Crown and Bridge Fabrication:

Dental ceramic furnaces are extensively used in the fabrication of dental crowns and bridges. These restorations are typically made from ceramic materials that are fired in the furnace to achieve the desired strength, fit, and aesthetic appearance.

2. Veneer Production:

Dental veneers, which are thin shells of ceramic material used to enhance the appearance of front teeth, are often fabricated using dental ceramic furnaces. The firing process in the furnace helps create veneers with the desired translucency and color properties for a natural-looking smile.

3. Inlays and Onlays:

Dental ceramic furnaces are employed in the production of inlays and onlays, which are indirect restorations used to restore damaged or decayed teeth. The furnace ensures that the ceramic material used for these restorations is properly fired, resulting in restorations that fit precisely and provide long-lasting durability.

4. Implant Prosthetics:

Dental ceramic furnaces play a vital role in the fabrication of ceramic components for dental implants. These components, such as implant abutments and implant-supported crowns, are fired in the furnace to achieve the necessary strength and aesthetics for successful implant restorations.

5. Orthodontic Appliances:

Dental ceramic furnaces are also utilized in the production of orthodontic appliances, such as ceramic brackets. These appliances are fired in the furnace to ensure that they are strong and durable enough to withstand the forces exerted during orthodontic treatment.

6. Dental Laboratory Research and Development:

Dental ceramic furnaces are used in dental laboratories for research and development purposes. They enable testing and refinement of new ceramic materials, firing techniques, and restoration designs to improve the quality and performance of dental restorations.

Dental ceramic furnaces are integral to the production of high-quality and aesthetically pleasing dental restorations. Their versatility and precise firing capabilities make them essential tools in dental laboratories and clinics for a wide range of applications in restorative and cosmetic dentistry.

Benefits

The use of dental ceramic furnaces in the dental industry offers several benefits:

1. Customization and Aesthetics:

Dental ceramic furnaces allow for the customization of dental restorations by providing precise control over the firing process. This enables dental technicians to achieve the desired shade, translucency, and natural appearance of the ceramic restorations, resulting in aesthetically pleasing outcomes that blend seamlessly with natural teeth.

2. Strength and Durability:

Firing dental ceramics in specialized furnaces helps enhance the strength and durability of the restorations. The controlled heating and cooling process promotes proper crystallization and bonding of the ceramic material, resulting in strong and long-lasting dental restorations that can withstand the forces of normal oral function.

3. Biocompatibility:

Dental ceramic materials used in these furnaces are biocompatible, meaning they are well-tolerated by the oral tissues and have minimal risk of adverse reactions or allergies in patients. This ensures the restorations are safe and compatible with the oral environment.

4. Precise Firing Control:

Dental ceramic furnaces provide precise temperature control throughout the firing process. This level of control allows for consistency and repeatability in achieving the desired physical properties of the ceramic material, such as hardness, density, and shrinkage, resulting in reliable and predictable outcomes.

5. Time Efficiency:

Modern dental ceramic furnaces offer fast heating and cooling rates, reducing the overall processing time for dental restorations.

6. Versatility:

Dental ceramic furnaces are versatile and can accommodate a wide range of ceramic materials used in dental restorations, including porcelain, zirconia, and lithium disilicate. This versatility allows dental technicians to work with different materials and select the most suitable option for each patient’s specific needs.

7. Research and Development:

Dental ceramic furnaces play a crucial role in research and development activities in the dental field. They facilitate the testing and refinement of new ceramic materials, firing techniques, and restoration designs, contributing to advancements in dental technology and improving the quality of dental restorations.

Overall, dental ceramic furnaces provide dental professionals with the tools and capabilities to create durable, natural-looking, and patient-specific dental restorations that meet functional and aesthetic requirements.

FAQ

Q1: What types of ceramic materials can be fired in a dental ceramic furnace?

A1: Dental ceramic furnaces are designed to fire various types of ceramic materials used in dentistry, including dental porcelain, zirconia, lithium disilicate, and feldspathic ceramics.

Q2: How long does the firing process take in a dental ceramic furnace?

A2: The duration of the firing process in a dental ceramic furnace can vary depending on factors such as the type of ceramic material, the thickness of the restoration, and the specific firing parameters. Generally, the firing process can take several hours, with additional time for cooling.

Q3: Can a dental ceramic furnace be used for multiple restorations simultaneously?

A3: Yes, dental ceramic furnaces are designed to accommodate multiple restorations simultaneously. However, it’s important to ensure that the restorations are properly spaced and positioned to allow for even heat distribution and prevent contact or interference between them during firing.

Q4: How long can delivery?

A4: Normally, 3-7 days after confirming order. We have in stock, after testing and packing, will delivery at the first time.

More Solutions for Your Dental Laboratory

Please visit our website [Dental Laboratory Collection]