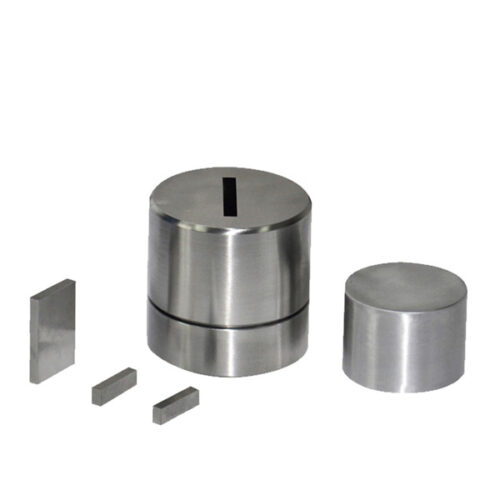

Cylindrical Split Mold

Details

The cylindrical split mold, also known as an easily removable modular mold, is a commonly used tablet compression mold in laboratories.

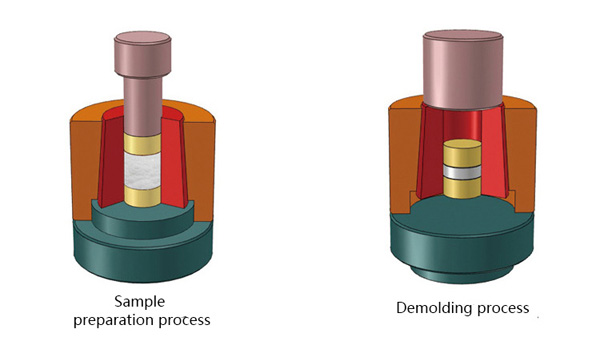

It typically consists of three internal cores combined to form a cylindrical cavity, with the diameter of this cavity representing the size of the pressed powder sample.

The three internal cores are secured as a single unit by placing a circular sleeve around them.

After compression, the mold can be quickly disassembled by removing the sleeve, separating the three internal cores. The powdered sample can then be directly collected without the need for a demolding process, avoiding the risk of sample fracture or damage during demolding.

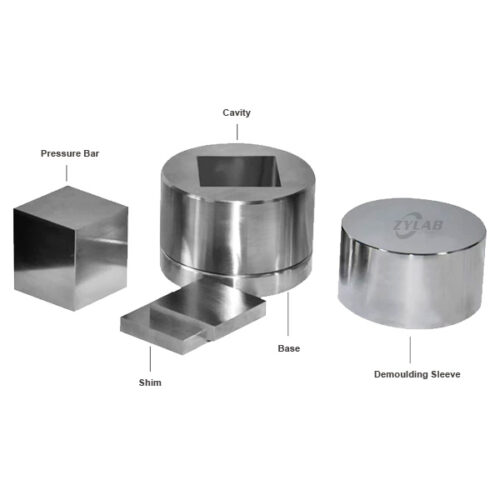

Cylindrical split mold with easy demolding belong to laboratory consumables, typically comprising a mold base, mold cores (three petals), mold sleeve, mold pressure rod, mold spacer, and demolding sleeve.

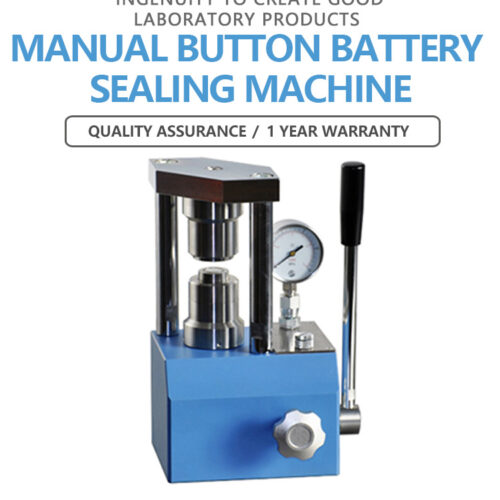

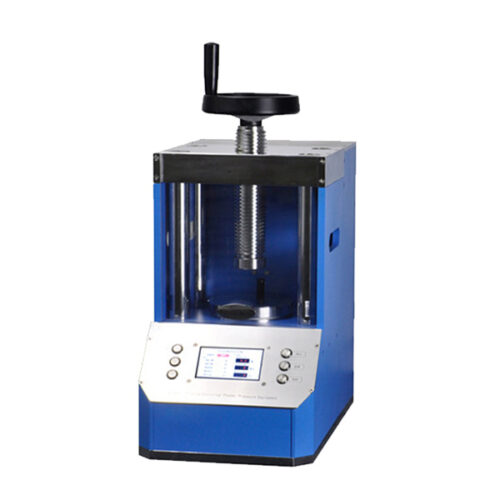

Click here to view the lab tablet press.

To grind the required materials into powder with the correct particle size ( from millimeters to micrometers), we recommend using our planetary ball mill and accessories or agate mortar and pestle set.

Applications

Cylindrical split mold are mainly used for pressing powder samples that are difficult to form or demold.

When used with a tablet press, they can be utilized to press various powder materials, such as potassium bromide (KBr), sodium chloride (NaCl), silicon dioxide (SiO₂), aluminum oxide (Al₂O₃), zirconium oxide (ZrO2), etc., to create circular samples, cylinders, or other shapes for scientific analysis and research.

They are widely applied in research, teaching, catalysis, testing, pharmaceuticals, chemical engineering, and the development of new materials.

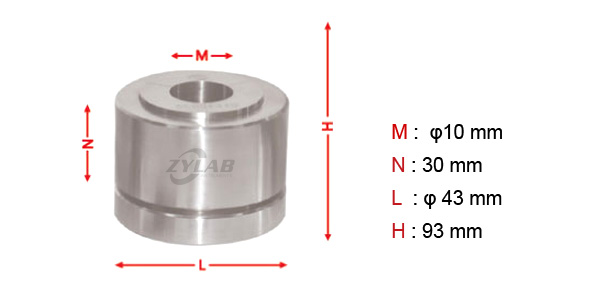

Parameter

| ZYLAB Cylindrical Split Mold | ||||||||

| Sample Size | 3-10mm | 12-20mm | 30mm | 40mm | 50mm | 60mm | 70mm | 80mm |

| Material | High Speed Tool Steel ASSAB+17 |

Alloy tool steel Cr12MoV | ||||||

| Indenter Hardness |

HRC68-HRC70 | HRC60-HRC62 | ||||||

| Cavity Depth | 30mm | 40mm | 50mm | 50mm | 55mm | 55mm | 60mm | 60mm |

| Boundary Dimension |

Φ43×93mm | Φ53×120mm | Φ73×133mm | Φ95×133mm | Φ115×150mm | Φ127×150mm | Φ153×180mm | Φ180×180mm |

| Weight | 0.75Kg | 1.2Kg | 3.8Kg | 6.3Kg | 14Kg | 20Kg | 30Kg | 40Kg |

Specifications

The standard dimensions of ZYLAB cylindrical split molds include Φ3mm, Φ4mm, Φ5mm, Φ6mm, Φ8mm, Φ10mm, Φ12mm, Φ13mm, Φ15mm, Φ18mm, Φ20mm, Φ30mm, Φ40mm, Φ50mm, Φ60mm, Φ70mm, and Φ80mm.

Custom sizes are available upon request, with delivery times ranging from 3 to 20 days.

If you need more detailed information, please contact us immediately. We offer free quotes on all products!

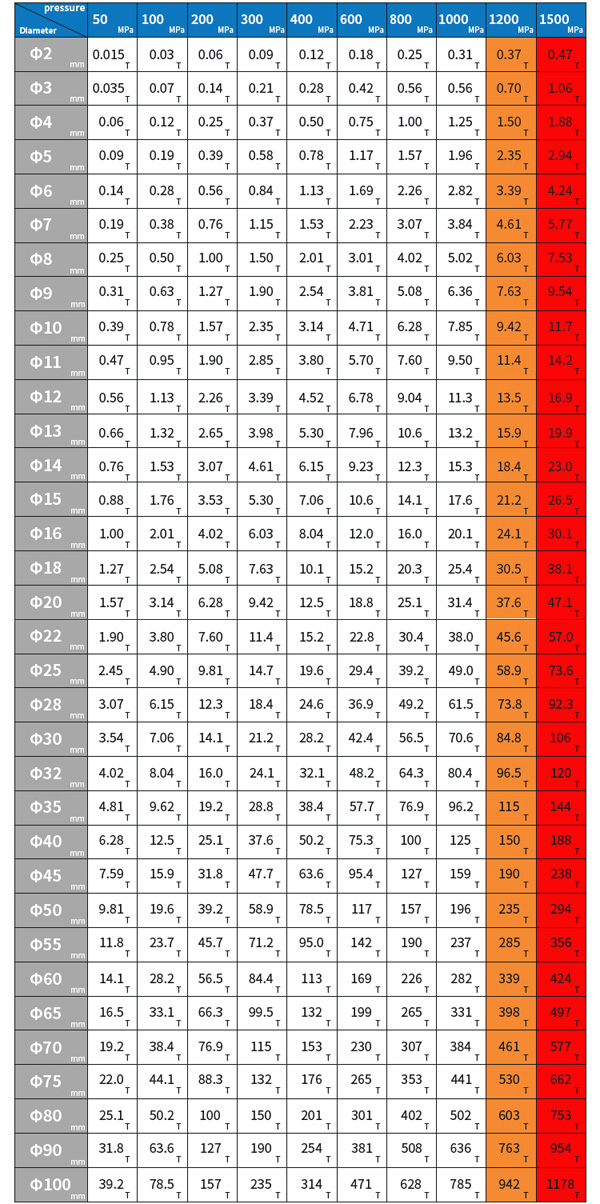

Pressure Matching

Note: Molds are generally used within the pressure range of 100-800 MPa and can reach up to 1500 MPa.

Operational Diagram of Cylindrical Split Mold

Usage and Maintenance

- Before each use, clean the surface of the mold with lint-free paper to remove any anti-rust oil, as it may affect the accuracy of sample test results.

- Place the mold at the center of the tablet press, ensuring the applied pressure does not exceed the mold’s maximum pressure capacity.

- After use, promptly clean any remaining sample from the mold to prevent corrosion.

- If residual samples on the mold surface cannot be removed, avoid using chemical reagents for cleaning or soaking.

- For long-term storage, apply anti-rust oil to the mold and store it in a dry environment.