Bridgman Crystal Growth Furnace

Introduction:

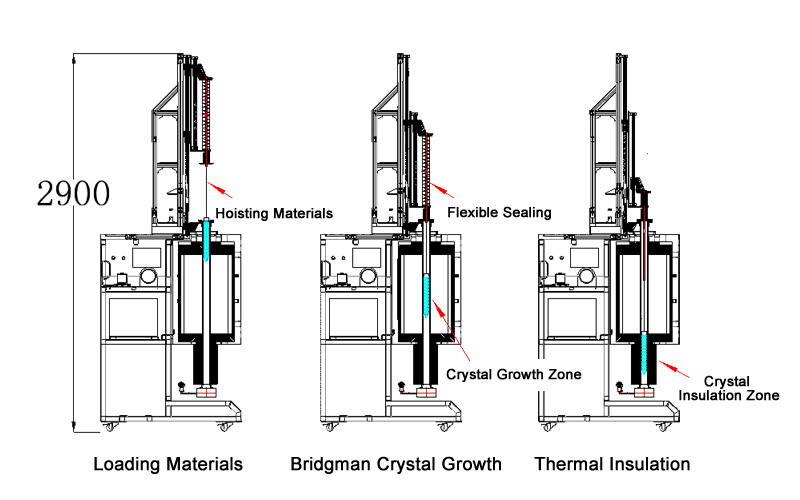

The crystal growth furnace is suitable for Bridgman method (crucible descent method), crystal growth under vacuum, protective atmosphere, or oxidizing atmosphere.

It can store up to 15 sets of process curves, including temperature, gas flow rate, crystal feeding speed (crystal growth rate), and can be switched arbitrarily. When crystal growth is complete, it provides alarm prompts, generates experiment reports, and exports data (including but not limited to temperature, gas flow rate, feeding rate, etc.).

Main Features:

1. Unique internal gradient temperature zone program for easily finding required temperature gradients.

2. Grating ruler for real-time sample position detection and accurate measurement of sample displacement.

3. Unique high-low-speed switching mode for easy sample handling and satisfying both low-speed and high-speed crystal growth operations. Speed is continuously adjustable, with crystal growth speed ranging from 30 to 20,000 um/h.

Technical Parameters of Crystal Growth Furnace:

| Item | Configuration | |

| Heating System

|

Crystal Growth Environment Selection | Oxidizing atmosphere/Protective atmosphere/Vacuum state |

|

Crystal Growth Temperature Zone Selection |

Single temperature zone: 200mm /300mm/400mm

Dual temperature zone : 100+100/200+200mm /300+300mm Three temperature zone:200+200+200mm |

|

| Reaction chamber size selection | Φ50/Φ60/Φ80/Φ100 (contact customer service for more options) | |

| Maximum

working temperature |

1150℃/1650℃ | |

| Temperature control accuracy | 300~1150±0.5℃ | |

| Furnace chamber material | High-purity polycrystalline fiber composite refractory insulation layer | |

| Furnace chamber mode | Circular heating integral sealing | |

| Sealing method | Water-cooled stainless steel sealing flange | |

| Pulling System

|

Crystal Growth Mode | Crucible descent method |

| Material loading mode | Hanging loading and pushing mode/Bottom loading mode | |

| Crystal movement mode selection | Only crucible movement/Crucible movement and rotation | |

| Structure | Double-layer slide rail structure, C7 large pitch ball screw, SPY aluminum support hard optical axis linear guide | |

| Crystal feeding system | Servo feed with high precision, smooth operation, and high torque harmonic reduction. Feeding speed is adjustable from 30μm/hr to 30000μm/hr. Material feeding mode is bottom pushing without rotation | |

| Loading sealing method | Electric sealing flange | |

| Loading sealing motor | 57CM23 closed-loop stepping motor, stable and high-speed | |

|

Gas Supply System

|

Flowmeter selection | 1/2/3-channel proton flowmeter 100sccm, 200sccm, 500sccm |

| Gas pipeline core | Special stainless steel gas pipeline (1/4″) | |

| Regulating valve type | Manual regulating valve | |

| Pipeline normal state | Normally closed | |

| Measurement accuracy | ±1.0%F.S | |

| Linearity | ±0.5%F.S | |

| Reproducibility | ±0.2%F.S | |

| Pressure range | -0.1-0.15 MPa | |

| Response time | 2S | |

| Operating environment temperature | (15~50℃) | |

| Vacuum System

|

Vacuum type selection | 4C vacuum pump/ 103(A) molecular pump system |

| Vacuum gauge type | Digital vacuum gauge/Analog vacuum gauge | |

| System vacuum | ≤5pa /2.8*10-3pa | |

|

Control System

|

Control mode |

1. Sintering process curve setting: dynamically display and set curves. Multiple sintering processes can be pre-stored in the device, with each curve freely set. |

2. Scheduled sintering, achieving unattended sintering of process curves. | 3. Real-time display of sintering power, voltage, etc., and recording sintering data, which can be exported for paperless recording. | 4. Remote control implementation, real-time observation of equipment status. | 5. Temperature correction: Non-linear correction is performed throughout the sintering process based on the difference between the main control temperature and the sample temperature. |

| Crystal Growth Process Setting | Up to 15 sets of process curves can be pre-stored, including temperature, gas flow rate, crystal feeding speed (crystal growth rate), and can be called arbitrarily. After crystal growth is complete, alarm prompts are provided, and an experiment report is generated and exported, including (but not limited to) temperature, gas flow rate, feeding rate, etc. | |

| Temperature Correction | Non-linear correction is performed throughout the system based on the difference between the main control temperature and the sample temperature (inquire customer for specific crystal growth temperature points for special verification) | |

| Functional Implementation | Applicable to various crystal growth processes under vacuum, atmosphere, or air according to the Bridgman method (crucible descent method) | |

| System Protection | Over-temperature alarm, over-current protection, disconnection prompt | |

| Product Configuration | 1 reaction chamber, 5 meters of nichrome wire, 1 manual (random tools, etc.) | |

| Service Items | Transportation and insurance, packaging, installation and technical service fees; 12 months warranty, 24 months for touchscreen system, lifetime support. |

FAQ:

- What is a Bridgman crystal growth furnace?

- A Bridgman crystal growth furnace is a specialized piece of equipment used in materials science and crystallography to grow single crystals of various materials. It allows for controlled solidification of a material from a melt, resulting in the production of large, high-quality single crystals with uniform properties.

- How does a Bridgman crystal growth furnace work?

- The furnace works by heating a material to its melting point and then slowly cooling it under controlled conditions. A temperature gradient is established within the furnace, directing the solidification process in a specific direction. This allows for the growth of a single crystal with desired properties.

- What are the key components of a Bridgman crystal growth furnace?

- Key components typically include a heating system, temperature control mechanisms, a crucible or ampoule to contain the material, a seeding mechanism, a setup to establish a temperature gradient, and often a quenching mechanism for rapid cooling after crystal growth.

- What materials can be grown using a Bridgman crystal growth furnace?

- Bridgman crystal growth furnaces can be used to grow a wide range of materials, including semiconductors, optical materials, metals, alloys, and high-temperature superconductors.

- What are the applications of single crystals grown with Bridgman furnaces?

- Single crystals grown using Bridgman furnaces find applications in various fields, including semiconductor manufacturing, optical devices (such as lenses and lasers), high-temperature superconductors, and fundamental research in materials science.

- What are the advantages of using Bridgman crystal growth furnaces?

- The main advantages include the ability to produce large, high-quality single crystals with controlled properties, which are crucial for many scientific and industrial applications. Additionally, Bridgman furnaces offer flexibility in controlling crystal orientation and can accommodate a wide range of materials.