High-purity Alumina (Al2O3) Crucible for Tube Furnace

Introduction:

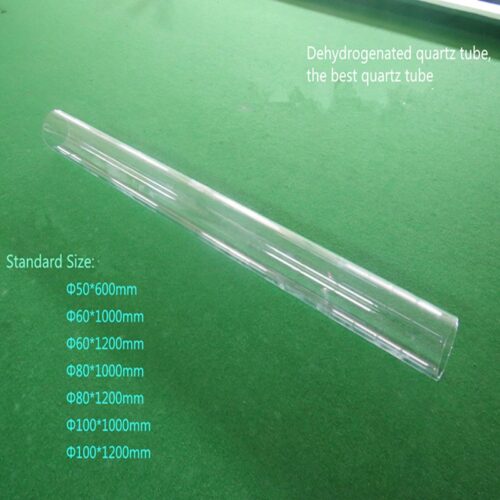

A crucible for a tube furnace is a vessel or container designed to hold and heat materials within the controlled environment of a tube furnace.

Tube furnaces are used for various heating applications such as annealing, sintering, calcination, and chemical vapor deposition (CVD).

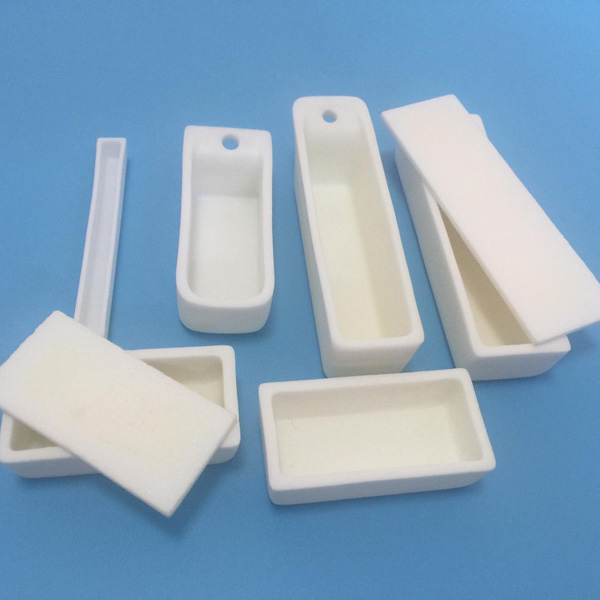

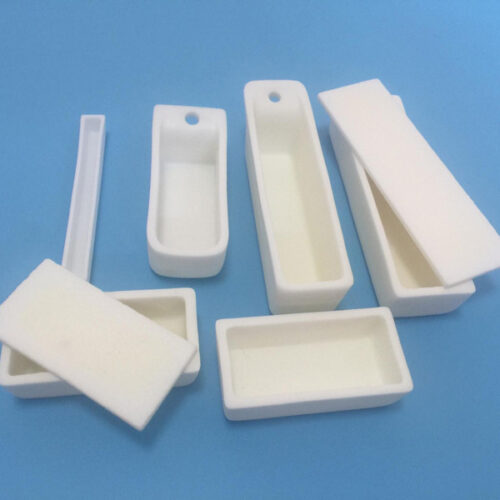

The crucible used in a tube furnace is typically made of refractory materials capable of withstanding high temperatures and chemical reactions.These crucibles come in various shapes and sizes, including arc-shaped, square, cylindrical, and boat-shaped, tailored to meet specific application requirements.

Crucibles usually consist of materials alumina (Al2O3), designed to endure the high temperatures and corrosive environments often encountered in tube furnace operations.

The crucible’s primary function is to contain the sample or material being processed, safeguarding it from direct contact with the heating elements while facilitating uniform heating and controlled reactions.

Alumina Purity: >99%

Maximum temperature resistance: 1750°C

Continuous operating temperature: ≤1600°C

The Uses of Crucibles in Tube Furnaces:

Annealing: Heating materials to specific temperatures and holding them there to relieve internal stresses, improve crystalline structure, or enhance material properties.

Sintering: Heating powdered materials to fuse them together without melting to form a solid mass, often used in the production of ceramics, metals, and composites.

Calcination: Heating materials to high temperatures to drive off volatile components, such as water or organic compounds, leaving behind a powdered residue.

Chemical Vapor Deposition (CVD): Depositing thin films of material onto a substrate by introducing gaseous precursors into the tube furnace, where they react and deposit onto the substrate surface.

Heat Treatment: Subjecting materials to controlled heating and cooling cycles to alter their physical or mechanical properties, such as hardness, ductility, or conductivity.

Crystallization: Growing single crystals or crystalline structures from a solution or melt by controlled cooling or evaporation processes.

Melting and Alloying: Heating materials to their melting point for casting, alloying, or mixing different materials together to form new compounds or alloys.

Styles of Crucibles for Tube Furnaces:

Alumina Crucibles Notes for Use:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute. When cooling, it is recommended to control the temperature by powering off gradually. Cooling too fast during the initial cooling phase after turning off the power may cause the product to crack.

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.