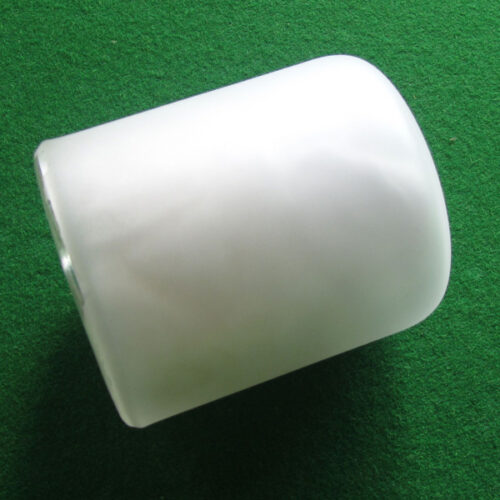

Ceramic Crucible For Lab Muffle Furnace

Introduction:

A crucible for a muffle furnace is a vessel made of a material that can withstand high temperatures. It is typically used to hold materials that need to be heated to extreme temperatures without reacting with the crucible material itself..

The muffle furnace provides a controlled environment for high-temperature applications such as annealing, sintering, calcination, or heat treatment of materials.Researchers place the crucible inside the furnace chamber and heat it to the desired temperature.

Styles of Crucibles for Muffle Furnaces:

The Application of Crucibles in Muffle Furnaces Includes:

Sintering and Heat Treatment: Researchers commonly use muffle furnaces to perform high-temperature sintering and heat treatment on materials such as ceramics, metals, or compounds. Crucibles have the capability to contain samples and effectively protect and process them at high temperatures.

Elemental Analysis: In analytical chemistry, researchers can utilize crucibles to ash samples, thereby facilitating further analysis of their components.

Melting Experiments: Crucibles have the capacity to serve as containers for samples, enabling the accommodation and processing of melted substances.

Crystal Growth: In materials science and crystallography, researchers can employ crucibles as containers for conducting crystal growth experiments.

Catalyst Activity Testing: When researchers test the activity and stability of catalysts, they can use crucibles as sample containers and subject them to the necessary temperature cycles and treatments in the muffle furnace.