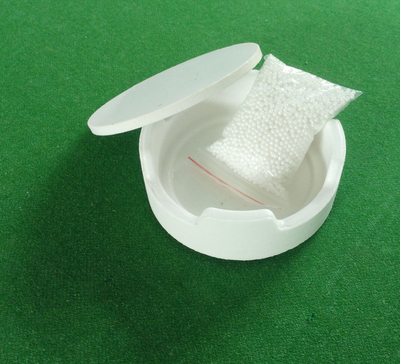

Alumina Crucible (Zirconia Sintering Crucible)

Material:

The alumina crucible is made from 99.70% high-purity alumina powder through compression molding.

Special Features:

- High porosity: It has a high porosity, which helps improve its thermal conductivity and thermal shock resistance.

- Strong thermal conductivity: The crucible exhibits excellent thermal conductivity, allowing for even heat distribution to dental prosthetics and preventing warping and deformation due to uneven heating.

- Reusability: Thanks to its special properties, the crucible can be reused multiple times.

- Structure and Dimensions:

- Outer diameter: 100mm

- Inner diameter: 90mm

- Height: 35 or 32mm

- Upper cover diameter: 100mm

- Upper cover thickness: 5mm

High-Temperature Performance:

- Insulation and mechanical strength: The alumina crucible exhibits good high-temperature insulation and mechanical strength.

- High thermal conductivity, low thermal expansion: The crucible has a high thermal conductivity and a low thermal expansion rate.

- Non-reactivity with specific gases: It does not react with air, water vapor, hydrogen, carbon monoxide, and other gases at temperatures above 1700℃.

- Short-term maximum operating temperature: It can withstand temperatures up to 1800℃.

These characteristics make the alumina crucible an essential accessory for the zirconia sintering process in dental prosthetics. It can be stacked in an alternating manner to increase the sintering quantity in the furnace. With excellent heat conduction and high-temperature resistance, it ensures a smooth sintering process for dental prosthetics.

Note:

Can choose with cover or not.

Applications:

Zirconia beads fill into the crucibles for application of sintering dental crown and teeth in dental labs.