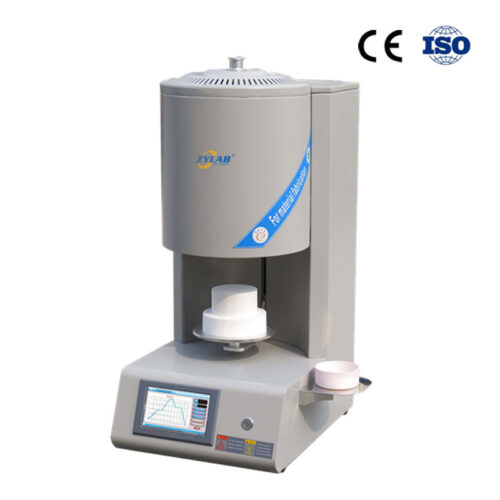

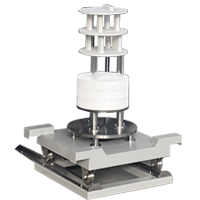

ZYLAB Clean Chamber Vacuum Furnace with Bottom Loading Design

Introduction:

The ZYLAB Clean Chamber Vacuum Furnace with Bottom Loading Design is specifically designed for high-temperature treatments in a vacuum or controlled atmosphere. Ideal for applications requiring uniform heating and staged temperature control, this furnace ensures that samples remain isolated from the external environment throughout the heating process, preventing contamination and oxidation.

The furnace is equipped with a ring heating bell and top auxiliary heating, allowing precise temperature control and even heat distribution.

Key Features:

1. Vacuum Atmosphere Control

- Vacuum Pump System: Equipped with a highly efficient vacuum pump, this system ensures the furnace reaches the desired vacuum level, providing an oxygen-free or controlled atmosphere for heating processes.

- Atmosphere Control System: Inert gases such as argon or nitrogen can be introduced to maintain a stable atmosphere, preventing oxidation or unwanted reactions.

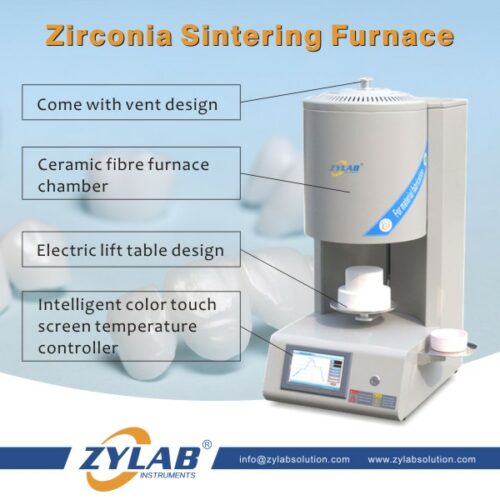

2. Ring Heating Bell Structure

- Ring Heating Elements: The furnace utilizes ring-shaped heating elements surrounding the sample, providing even heat distribution for consistent temperatures at all points on the sample surface.

- Bell Design: The bell-shaped structure enhances heating efficiency and makes sample loading and unloading easier while minimizing heat loss.

3. Top Auxiliary Heating

- Top Heater: An additional top heater complements the ring heating zone, ensuring minimal temperature differences between the top and bottom of the sample, ideal for high-precision temperature control.

4. Precise Temperature Control

- PID Control: Advanced PID algorithms provide precise temperature control, ensuring the heating curve aligns with preset parameters.

- Real-time Monitoring: Equipped with high-accuracy temperature sensors to continuously monitor temperature fluctuations, ensuring stable and reliable process conditions.

5. Automatic Lifting Function

- Electric Drive: The sample platform can be smoothly raised or lowered electrically, accommodating various sample sizes and weights.

- Position Feedback: Integrated encoders or displacement sensors provide accurate position feedback, ensuring the sample is at the desired height.

- Programmable Control: The system allows you to set lifting paths and speeds via a computer or touch screen interface, simplifying the operation and enhancing automation.

Applications:

-

Materials Science Research

Ideal for synthesizing advanced materials and studying material properties under high-temperature and controlled atmosphere conditions. -

Metallurgical Industry

Used for metal melting, alloy preparation, and vacuum sintering, ensuring high material purity by preventing contamination from the external environment. -

Semiconductor Manufacturing

Performs stress-relief annealing and wafer processing before chip packaging, enhancing electrical properties and improving product reliability. -

Chemical Industry

Suitable for catalyst activation, organic synthesis, and other chemical reactions requiring precise temperature control and inert/vacuum atmospheres. -

Laboratory and Academic Research

Provides a reliable and flexible heating platform for universities, research institutes, and laboratories conducting high-level scientific research.

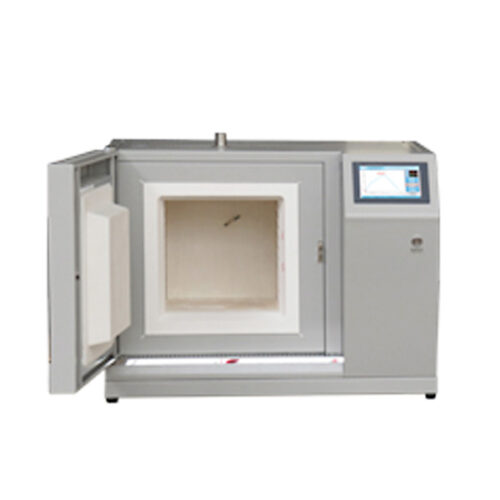

Technical Specifications of Clean Chamber Vacuum Furnace:

| Model | B1200 | |

| Power Supply | Three-phase 380V 50HZ | |

| Rated Power | 16.5KW | |

| Number of Heating Zones | Two-point temperature control | |

| Heating Structure | Annular heating bell + Top auxiliary heating | |

| Temperature Measuring Element | K-type thermocouple Φ2*420mm | |

| Max Temperature (Tmax) | 1200°C | |

| Rated Temperature | 1100°C | |

| Heating Rate | 1°C/H – 20°C/Min | |

| Furnace Zone Dimensions | φ350mm * 320mm * 2 (2 zones) | |

| Quartz Sleeve Dimensions | φ300mm * 780mm | |

| Three-Layer Quartz Tray Diameter | φ260mm (interlayer spacing 100mm) | |

| Maximum Sample Size | φ200mm * 220mm | |

| Furnace Dimensions | L1460mm * H2100mm * D1360mm | |

| Float Flowmeter | 0.5-8L/min | |

| Furnace Weight | Approx. 610KG | |

| Control System |  |

|

| Temperature Accuracy | ±1°C | |

| Heating Elements |  |

HRE High-temperature alloy wire |

| High Purity Alumina Fiber Furnace Tray |  |

|

| Clean Quartz Chamber |  |

|

| Gas Supply System |  |

Furnace body reserves two float flowmeter inlets controlled by an electric control system and electromagnetic valve, then merged into a gas preheater before entering the reaction chamber. The post-reaction gases are exhausted through the top exhaust port. |

| Service Support | 1-year warranty, lifetime support (consumable parts such as quartz products and sealing rings are not covered under warranty) | |

Why Choose ZYLAB Clean Chamber Vacuum Furnace?

- High Purity Heating Environment

- Precise Temperature and Atmosphere Control

- Bottom Loading for Easy Handling and Safe Operation

- Ideal for Research, Development, and Industrial Applications

Precautions for Equipment Operation:

-

High-Temperature Quartz Tube Warning

When the furnace temperature is ≥ 300°C, after moving the furnace chamber, do not touch the quartz tube at the previous furnace position to avoid burns or injury. -

Do Not Open Furnace Chamber at High Temperature

When the furnace temperature is ≥ 300°C, do not open the furnace chamber, as this may result in serious injury due to high heat. -

Pressure Limitation During Operation

During equipment operation, the internal pressure of the furnace tube must not exceed 0.125 MPa (absolute pressure) to prevent damage to the equipment due to excessive pressure. -

Vacuum Use Temperature Limit

When operating under vacuum conditions, the maximum allowable temperature is 800°C. Exceeding this may cause equipment failure or damage. -

Use of Gas Supply Cylinder

Gas cylinders typically contain high internal pressure. When introducing gas into the furnace tube, a pressure-reducing valve must be installed on the gas cylinder.

It is recommended to use a low-pressure regulator with a range of 0.01 MPa to 0.15 MPa, which provides more accurate and safer control during experiments. -

Avoid Vacuum State at High Temperatures

When the furnace temperature exceeds 1000°C, the furnace tube must not be in a vacuum state. The internal pressure of the tube should be equal to atmospheric pressure, maintaining a normal pressure environment. -

Quartz Tube Long-Term Temperature Limit

For high-purity quartz tubes, the recommended long-term operating temperature is ≤ 1100°C. Exceeding this temperature may shorten the service life or damage the tube. -

Gas Valve Operation During Heating

It is not recommended to close both the exhaust valve and the inlet valve on the flange ends during heating experiments.

If the gas valves must be closed during sample heating, carefully monitor the pressure gauge at all times.

If the absolute pressure exceeds 0.15 MPa, the exhaust valve must be immediately opened to release pressure and prevent accidents, such as furnace tube rupture.

FAQ:

1. What are the benefits of using a vacuum atmosphere?

The vacuum atmosphere ensures that your samples are heated in an oxygen-free or controlled environment, preventing oxidation and unwanted chemical reactions. This is especially important for processing sensitive materials like metals, alloys, semiconductors, and advanced ceramics.

2. How does the ring heating bell structure work?

The furnace uses ring-shaped heating elements that surround the sample, ensuring even and consistent heat distribution. This design helps prevent hot spots and provides uniform heating, which is crucial for high-precision heat treatment processes.

3. What is the maximum temperature this furnace can reach?

The furnace can reach a maximum temperature of 1200°C, making it suitable for a wide range of high-temperature applications, including sintering, annealing, and catalyst activation.

4. Can the furnace be used for semiconductor processing?

Yes, the ZYLAB Clean Chamber Vacuum Furnace is commonly used in semiconductor processing, such as for annealing wafers or stress-relief treatments. The clean chamber and precise temperature control make it ideal for handling sensitive materials like semiconductor wafers and components.

5. How do I control the furnace’s lifting mechanism?

The furnace is equipped with an electric drive system that allows for smooth and precise lifting of the sample platform. You can program the lifting speed and path through the computer or touch screen interface, making the process automated and user-friendly.

For More Bottom Loading Furnaces / Bell Furnaces

Please visit our website [Bottom Loading Furnaces Collection]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]