1200.C Chamber Furnace with Lift-Up Door/Opens from Bottom Up

Introduction

The 1200.C Chamber Furnace with Lift-Up Door is a laboratory device specifically designed for high-temperature heat treatment. It is widely used in material science, metallurgy, chemical engineering, ceramics, and other fields. The furnace features a hydraulic system for controlling the door, ensuring safe and convenient operation while maintaining excellent sealing performance under high temperatures. With a maximum temperature of 1200°C, it is suitable for sintering, ashing, pyrolysis, and other processes involving various samples.

Key Features

- Hydraulic Drive System

- Safe and Reliable: Advanced hydraulic technology enables smooth and rapid opening and closing of the furnace door, reducing mechanical wear and extending equipment lifespan.

- Precise Temperature Control System

- High-Precision PID Regulation: Incorporates advanced PID control algorithms and supports multi-step temperature programming, ensuring precise and stable temperature control with excellent repeatability.

- Real-Time Monitoring: The touchscreen interface provides real-time temperature curve monitoring and data recording for convenient analysis and report generation.

- Excellent Sealing Performance

- High-Temperature Seal: Special high-temperature-resistant seals around the door ensure reliable sealing, even at elevated temperatures, preventing external air intrusion that could affect experimental results.

- User-Friendly Design

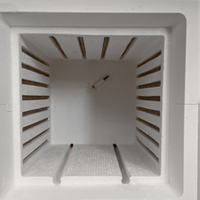

- Spacious Chamber: A large heating chamber accommodates larger samples or multiple samples simultaneously.

- Easy to Clean: The simple internal structure facilitates cleaning and maintenance, reducing residue impact on subsequent experiments.

- Easy to Operate: The intelligent 7″ color touch screen controller provides simple operation and a clear heating process.

Technical Parameters

| Model | M1200-20 |

| Maximum Temperature | 1200°C |

| Rated Temperature | 1150°C |

| Touchscreen Size | 7.0″ |

| Heating Rate | 1°C/H – 20°C/Min |

| Sensor Type | K-Type Thermocouple |

| Rated Power | 4 KW |

| Chamber Dimensions | 200×200×300(D) mm |

| External Dimensions | 530×700×580 mm |

| Control System | Intelligent Touchscreen Controller

1. Embedded operating system with a bilingual graphical interface (Chinese/English), 7-inch true-color touchscreen input, smart human-machine interaction mode, and non-linear sample temperature correction. 2. Stores up to 15 curves, each configurable with 30 “time-temperature” programs, saving time on repetitive curve modifications. 3. Features over-temperature alarms, thermocouple disconnection prompts, and leakage protection.

|

| Temperature Accuracy | ±1°C |

| Heating Element | Top Quality Resistance wire

|

| Net Weight | 64 KG |

| Service and Support | One-year limited warranty with lifetime support |

Which kinds of industry can use this 1200.C Chamber Furnace?

College & Universities, New Material Research, New Energy, Powder Metallurgy, Electronics, Ceramic, Chemistry, Medicine,etc.

Applications of 1200.C Chamber Furnace with Lift-Up Door

- Material Synthesis and Sintering

- High-temperature synthesis and sintering of metallic powders, ceramics, and advanced composite materials.

- Processing of new materials for industrial and research applications.

- Thermal Treatment

- Annealing, tempering of metals and alloys.

- Decomposition and calcination processes for chemicals and materials.

- Chemical Analysis

- Ashing of organic and inorganic samples for compositional analysis.

- Thermal decomposition experiments for studying material properties.

- Environmental Testing

- Analysis of soil, sludge, and waste materials for contaminants or valuable compounds.

- Preparation of samples for environmental monitoring and research.

- Laboratory Research and Development

- Conducting heat treatment experiments in universities, research institutes, and industrial R&D labs.

- Development and testing of novel materials and coatings.

- Ceramic and Glass Production

- Firing and sintering of ceramic components, glazes, and glass materials.

- Small-scale production and quality testing of ceramic goods.

- Energy and Electronics

- Processing of materials for battery research, such as cathodes and anodes.

- Fabrication and testing of semiconductor and electronic components.

The lift-up door design improves safety and ergonomics, making the furnace particularly suitable for high-frequency use in laboratories and production environments.

For More Options on Chamber Furnaces

Please visit our website [Chamber Furnaces Collection]