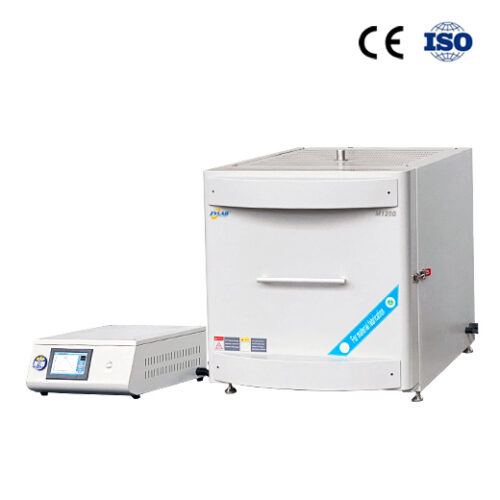

ZYLAB Box Furnace with Separated Controller

Introduction

ZYLAB 5-Side Heating Box Furnace with Separated Controller is a glovebox-compatible laboratory furnace designed for advanced thermal processing of sensitive materials. Featuring a separated programmable controller, this box furnace provides flexible installation, exceptional temperature uniformity, and precise control, making it ideal for materials research, metallurgy, ceramics sintering, and semiconductor post-processing.

With a maximum temperature of 1200°C and a large 64L heating chamber, this unit delivers high uniformity through its five-sided heating design (bottom + 4 walls), significantly reducing temperature gradients and improving experimental consistency. Its modular design is especially suitable for integration with gloveboxes, ensuring safety, airtightness, and operational efficiency in controlled atmospheres.

Key Features

1. Separated Design – Ideal for Glovebox Integration

-

Flexible Installation: The heating chamber and controller can be installed independently to adapt to various lab configurations.

-

Safe Glovebox Integration: The heating chamber fits inside a glovebox while the control unit remains outside, saving space and improving safety for inert or hazardous environments.

2. 5-Side Heating System

-

Uniform Heat Distribution: Bottom and four-wall heating ensure homogenous temperature distribution throughout the chamber.

-

Fast Heating: High-efficiency heating elements and optimized layout enable rapid temperature ramp-up, improving lab productivity.

3. Precision Temperature Control

-

PID Control System: Equipped with an advanced PID controller for high-precision temperature regulation (±1°C accuracy).

-

Real-Time Monitoring: High-accuracy thermocouple constantly monitors chamber temperature to maintain process stability.

4. Glovebox Compatibility

-

Sealed Chamber Construction: Uses high-quality sealing materials to ensure airtight operation inside gloveboxes.

-

Standard Interfaces: Equipped with ports and connectors compatible with most commercial gloveboxes for seamless integration.

5. Safety and Maintenance

-

Over-Temperature Protection: Built-in protection system cuts off power in case of abnormal temperature rise.

-

Emergency Stop Button: Clearly labeled for immediate shutdown in emergency situations.

-

Maintenance Reminders: System can prompt routine maintenance to help extend equipment lifespan.

Applications of Box Furnace with Separated Controller

-

Materials Science: Precision heating for studying physical and chemical behavior of new materials.

-

Glovebox Operations: Ideal for thermal processing of air-sensitive or hazardous samples in inert gas environments.

-

Ceramic & Glass Processing: Sintering, annealing, and melting processes at controlled high temperatures.

-

Metallurgical Treatment: Reducing metal powders and preparing high-performance alloys.

-

Semiconductor Processing: Wafer annealing, oxide reduction, and surface conditioning.

Technical Specifications of Box Furnace with Separated Controller

| Model | M1200-40 | |

| Power Supply | Three-phase, 380V, 50Hz | |

| Rated Power | 10 kW | |

| Heating Zones | Single zone, single control (5-side heating) | |

| Temperature Accuracy | ±1°C | |

| Thermocouple Type | K-type (φ2 × 600 mm) | |

| Heating Element | Mo-doped Fe-Cr-Al alloy resistance wire | |

| Maximum Temperature (Tmax) | 1200°C | |

| Rated Operating Temperature | 1150°C | |

| Recommended Heating Rate | ≤10°C/min | |

| Furnace Chamber Dimensions | 400 mm (L) × 400 mm (H) × 400 mm (D) | |

| SiC Shelf Plate Size | 390 mm (L) × 10 mm (H) × 390 mm (D) | |

| Furnace Dimensions (Closed) | 753 mm (L) × 792 mm (H) × 870 mm (D) | |

| Furnace Dimensions (Open) | 1320 mm (L) × 792 mm (H) × 900 mm (D) | |

| Control Cabinet Dimensions | 478 mm (L) × 228 mm (H) × 510 mm (D) | |

| Total Weight | Approx. 286 kg (including control cabinet) | |

| Control System |  |

|

| Heating Element |  |

Mo-doped Fe-Cr-Al alloy heating wire |

| Atmosphere Protection Box(Optional) |  |

Designed to create a controlled atmosphere inside the chamber. Prevents oxidation, contamination, and undesired reactions during heating. Customizable sizes available. |

| Temperature Uniformity Testing |  |

|

| Safety Notice |

|

|

| Warranty & Support | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. | |

Customization Options

ZYLAB offers flexible customization to meet a wide range of research and industrial processing needs. Optional features include:

-

Gas Inlet for Inert Atmosphere

Add a gas inlet to introduce inert gases such as argon or nitrogen for protective or purging purposes, and to help accelerate exhaust gas removal during heat treatment. -

Exhaust Outlet

Integrated gas exhaust port effectively removes by-products generated during material sintering or thermal processing, keeping the chamber environment clean and stable. -

Custom Chamber Size

The furnace chamber can be tailored to specific dimensions, accommodating various material sizes and process requirements.

Advantages of ZYLAB Furnaces

-

Flexible Customization – Designed to meet diverse laboratory demands

-

Widely Used in Research and Industry – Reliable performance in materials labs, universities, and production environments

-

Professional Support – Dedicated technical service and documentation

-

Efficient Logistics – Timely delivery and global shipment options

For More Content

Please read our blog: A Comprehensive Guide to Box Furnaces

For More Options on Box Furnaces

Please visit our website [Box Furnaces]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]