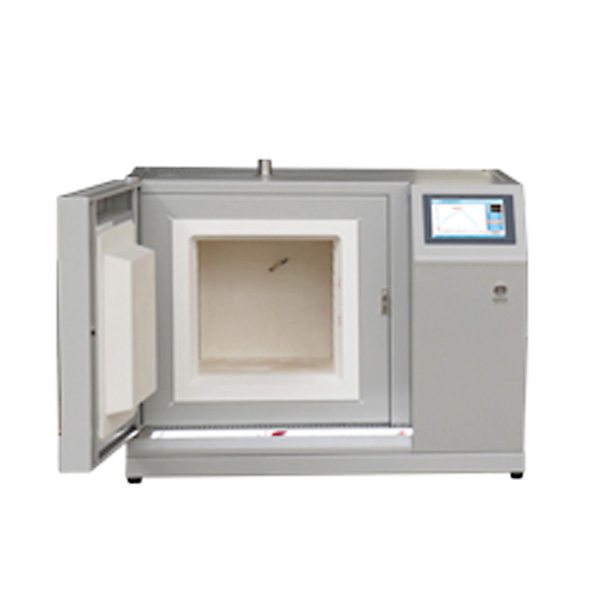

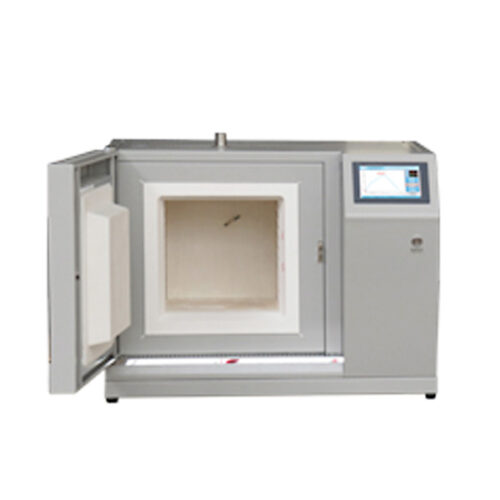

27L Intelligent Box Furnace 1200℃

Introduction:

This intelligent box furnace 1200℃ is specially designed and customized to meet customer needs, offering a high-cost-performance medium-temperature sintering furnace. With a simplified classic design process and a sintering chamber made of lightweight alumina fiber, it features touch screen controls for easy human-machine interaction, making operation more convenient!

Features and Benefits:

- Moderate Furnace Chamber Volume: Suitable for various material heat treatment processes.

- Advanced Insulating Materials: Made with advanced refractory insulation materials to minimize heat loss, effectively reducing the power consumption of the equipment.

- Modular Structure: Durable and easy to maintain.

- Exhaust Chimney on Top: Effectively removes volatile substances produced during the sintering process.

- Touch Screen Operation: Intuitive display of temperature curves.

Technical specifications:

| Model | M1200-30IT(B) | |

| Tmax | 1200℃ | |

| Rated Power | 7KW | |

| Sensor Type | K-type thermocouple | |

| Long-term Operating Temperature Range | 300~1150℃ | |

| Heating Rate | 1℃/H-20℃/Min | |

| Chamber Dimensions | W300*H300*D300mm | |

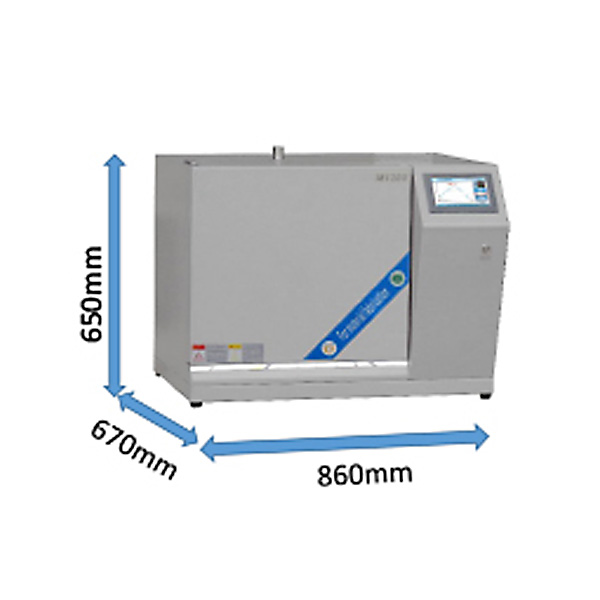

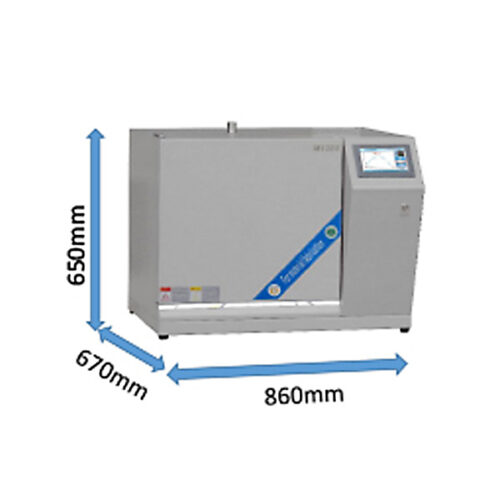

| External Dimensions | L860*H650*W670mm | |

| Control System |  |

|

| Temperature Accuracy | +/- 1℃ | |

| Heating Elements |  |

Mo-doped Fe-Cr-Al alloy |

| Net Weight | Approximately 120KG | |

| Service Support | 1-year warranty with lifetime support (excluding consumable parts under warranty) | |

Applications:

Here are some common applications for a 1200℃ box furnace:

- Sintering Ceramics: Ideal for sintering ceramic materials used in various industrial applications.

- Metal Heat Treatment: Suitable for annealing, tempering, and hardening various metal components.

- Materials Testing: Used in laboratories for testing material properties at high temperatures.

- Glass Processing: Perfect for annealing and tempering glass products.

- Powder Metallurgy: Used for sintering metal powders to create solid metal parts.

- Research and Development: Essential for R&D in materials science, metallurgy, and related fields.

- Electronic Component Manufacturing: Used in the production and testing of high-temperature electronic components.

- Composite Materials: Ideal for curing and processing advanced composite materials..

- Academic Research: Utilized in universities and research institutes for various scientific experiments and studies.

- Jewelry Making: Used for melting and shaping metals in the jewelry industry.

- Additive Manufacturing: Supports post-processing of 3D printed metal parts to enhance mechanical properties.

- Pharmaceuticals: Employed in the development and testing of new pharmaceutical compounds that require high-temperature stability tests.