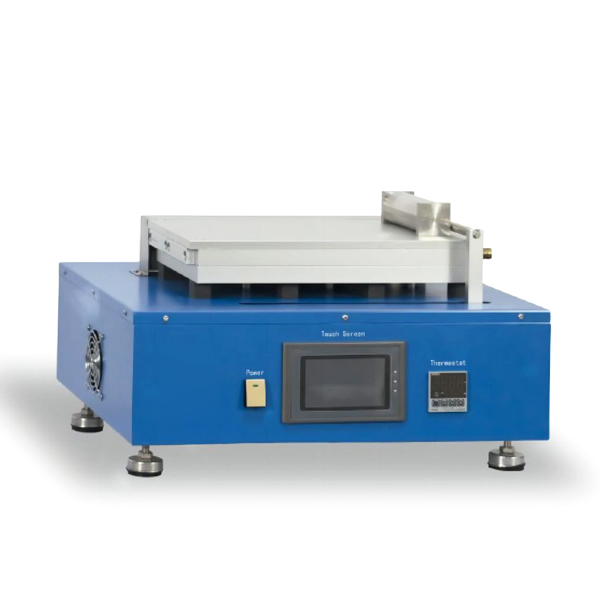

Bottom Heat Film Coater

Introduction:

This bottom heat film coater is widely used in various high-temperature coating research, such as ceramic films, crystal films, battery materials films, special nanometer films, and is capable of adapting to the development of scientific and technological processes for film formation under future high-temperature conditions.

Features and Benefits:

1. PLC and touchscreen control for convenient parameter settings observation.

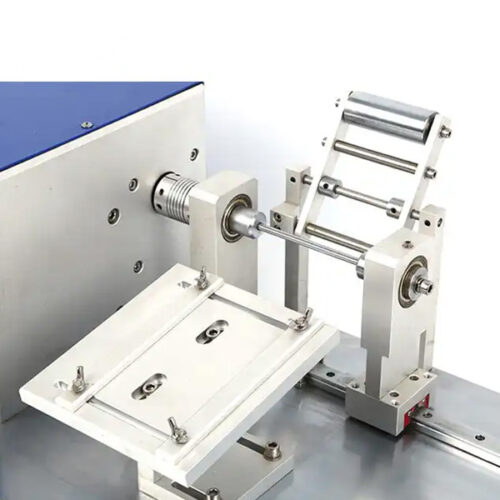

2. Micron-level scraper with high precision (accuracy of 0.01mm).

3. Adjustable coating speed within the range of 0~120mm/second.

4. Vacuum aluminum plate for quick placement or removal of substrates.

5. Touchscreen settings within the 0~300mm travel range.

6. Compact design to save space.

7. Exquisite appearance with sheet metal adopting geometric design for a clean and aesthetic look.

Main Parameters of Bottom Heat Film Coater:

- Bottom heating and drying system for the vacuum plate: Room temperature to 150°C, digital temperature controller with an accuracy of ±2°C.

- Coating speed: 0-120mm/second.

- Touchscreen settings within the 0-300mm travel range.

- Vacuum plate: Equipped with a vacuum aluminum flat plate.

- Vacuum plate dimensions: L415mm×W200mm×H32mm.

- Adjustable scraper thickness range: 0~5mm.

- Coating thickness control accuracy: 0.01mm.

- Includes an oil-free vacuum pump.

- Power supply: 220V/50Hz.

- Weight: 50KG.

- Dimensions: L550mm×W350mm×H320mm.

Applications:

This bottom heat film coater is widely used in various high-temperature coating research, such as ceramic films, crystal films, battery materials films, special nanometer films, and is capable of adapting to the development of scientific and technological processes for film formation under future high-temperature conditions.