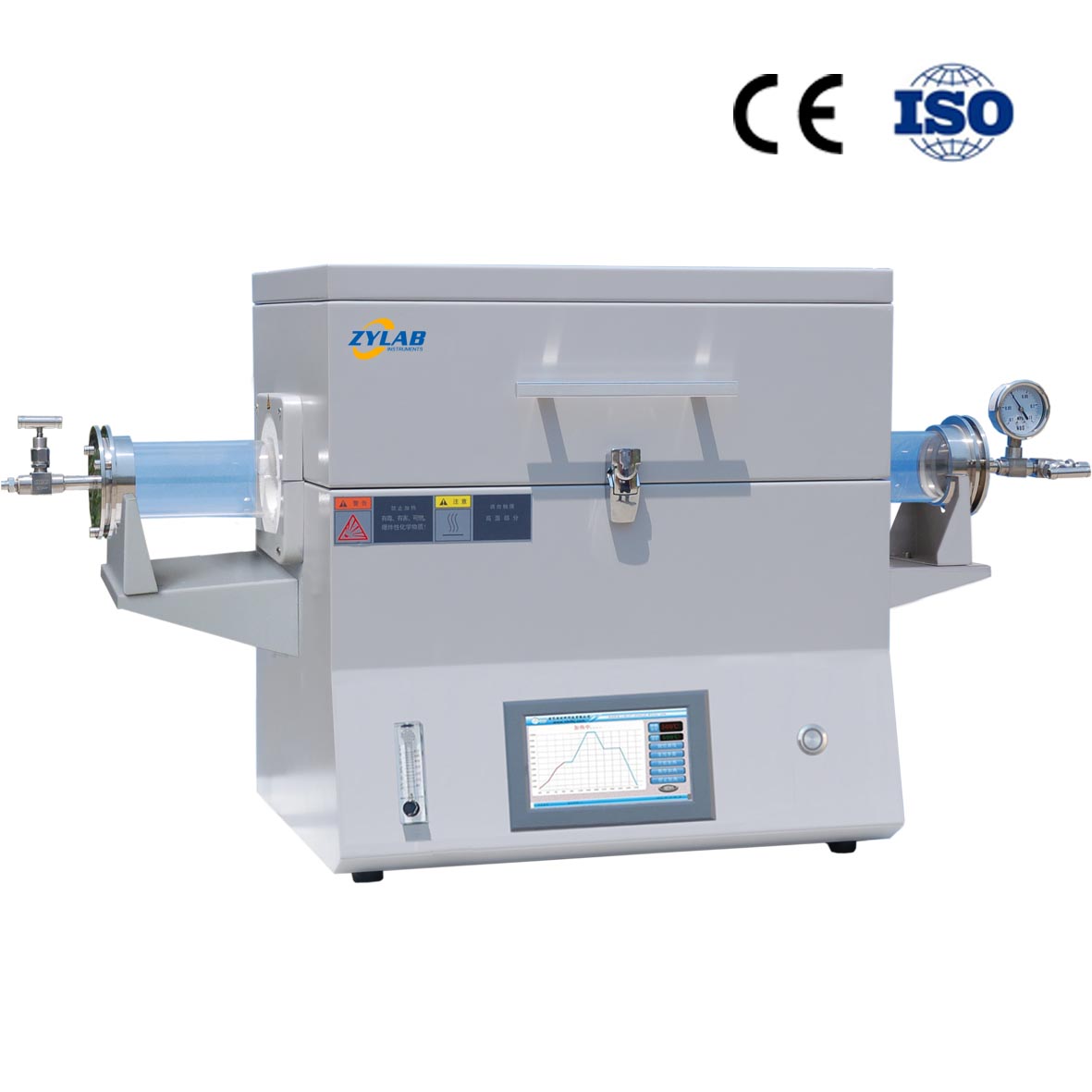

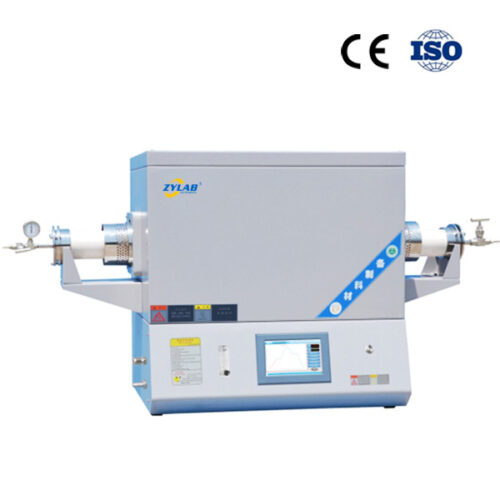

Biomass Pyrolysis Furnace

– Vacuum Tube Furnace for the Pyrolysis of Biomass Materials to Produce Biochar.

Applications:

Biomass pyrolysis furnace is utilized for the pyrolysis of biomass materials such as walnut shells, bamboo, straw, wood chips, etc., to generate biochar.

Highlight:

1.Quartz furnace tube with high purity and stainless steel flanges, ensuring excellent sealing performance.

2.Vacuum extraction capability, effectively isolating oxygen during the pyrolysis process.

3.Can be filled with inert gases such as nitrogen and argon for atmosphere protection.

4.Gases generated during pyrolysis can be expelled through the exhaust hole, preventing damage to the furnace by avoiding infiltration into heating elements.

5.Suitable for experiments with lighter samples; for heavier samples, a high-temperature steel furnace tube can be utilized.

Detail Features:

1. High purity quartz tube as furnace tube, max. temperature 1200.C, continue working temperature Rt –1100.C.

2. 7”Color Touch screen LCD man-machine English interface, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

3. 51 segments programmable and auto control.

4. Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different experimental processes.

5. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

6. By using special lining import from Japan and high quality alloy heating wire with excellent acid and corrosion resistance, protected against chemical contamination at the best and longer service life.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

8. Ring heating, open structure, convenient observation for operator, able to meet rapid sintering of small sample

9. Come with gas flowmeter, atmosphere sintering more convenient.

10. Unique flange has a multi-function hole.

11. Can add modules to contol and download data remotely(optional).

12. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for material research labs, also used in factory for small production.

Technical Parameters:

| Model | O1200-IT |

| Chamber Model | Open |

| Chamber Material | High quality import alumina fiber refraction insulation |

| Heating Element | High quality resistance wire |

| Max.temperature | 1200℃(<1hour) |

| Working Temperature | ≤1100℃ |

| Heating Rate | ≤20℃/min(advice:10℃/min) |

| Heating Zone | Single |

| Length of Heating Zone | 440mm |

| Constant Zone | 260mm |

| Tube Material | High Purity Quartz |

| Tube Sizes | Φ50×1000(mm

Φ60×1000(mm) Φ80×1000(mm) Φ100×1000(mm) |

| Sealing Mode | Vacuum Flange |

| Gas Tightness | 4.03×10-3Pa |

| Control Mode | Smart PID Control |

| Operating Interface | English Graphical Interface |

| Temperature Accuracy | +/- 1.C |

| Presetting Curve | 15 Presetting Curve, 51 Segments Programmable |

| Protection Setting | Over Temperature Alarm, Over Current Protection, Broken Thermocouple Protection |

| Thermocouple | K Type |

| Working Voltage | AC208-240V 50/60HZ |

| Standard Accessories | Quartz Tube, Vacuum Flange,Vacuum Gauge, Gas Flow Meter,Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |