Arc-shaped Alumina Crucible

Introduction:

Arc-shaped alumina crucible is typically arc-shaped and made of alumina (corundum) material, which is a type of refractory container with excellent high-temperature resistance and chemical stability.

This shape facilitates uniform heating of samples or substances at high temperatures and is easy to handle.

This type of crucible is commonly used for high-temperature experiments, such as melting metals or chemical reactions, and can also be used in fields such as metal smelting, chemical industry, and ceramic production.

Due to its refractoriness and chemical inertness, arc-shaped alumina crucibles can withstand extremely high temperatures without affecting the chemical properties of the samples, making them widely used in various experimental and industrial settings.

Manufacturing Process:

1. Making the mold for the product.

2. Making the raw body of the crucible.

3. Putting the finished raw body into the kiln for firing.

4. Sorting and storing the crucibles after they pass the inspection.

Advantages:

1. The product material is 99% alumina (Al2O3 > 99%), with high purity.

2. Adopting slip casting/pressing molding process.

3. Firing temperature is 1800°C, long-term use temperature ≤ 1600°C.

4. High temperature resistance and chemical corrosion resistance.

Our Offered Specifications for Arc-shaped Alumina Crucibles:

| Arc-shaped Alumina Crucible Specification Table | ||||||

| 3ml | 4ml | 5ml | 10ml | 15ml | 20ml | 25ml |

| 30ml | 40ml | 50ml | 100ml | 150ml | 200ml | 300ml |

| 200ml | 300ml | 350ml | 460ml | 500ml | 750ml | 1000ml |

| 1300ml | 1500ml | 2300ml | 3500ml | |||

| The crucible comes in standard and tall models. For detailed specifications and dimensions, please consult our professional customer service personnel. | ||||||

Applications:

1. Research on melting metals, melting rocks, or high-temperature reactions.

2. Can be used for heating, calcination, or melting treatment of samples.

3. Used for holding and handling molten metals or alloys.

4. Can be used for sintering ceramic materials or as a melting container for ceramic products.

5. Commonly used in various experiments, such as materials research, geology research, chemical synthesis, etc.

Related Equipment:

Alumina Crucible Usage Precautions:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute. When cooling, it is recommended to control the temperature by powering off gradually. Cooling too fast during the initial cooling phase after turning off the power may cause the product to crack.

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

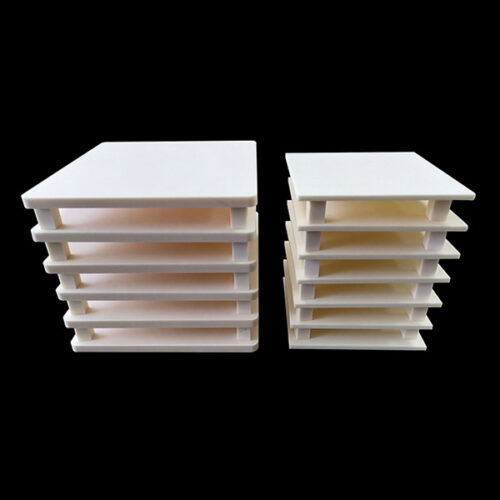

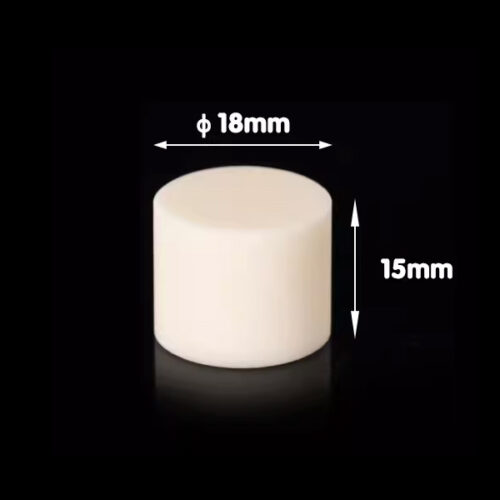

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.