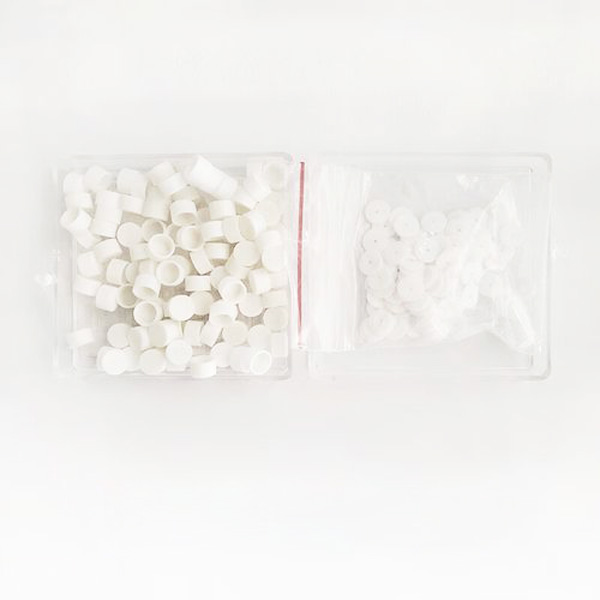

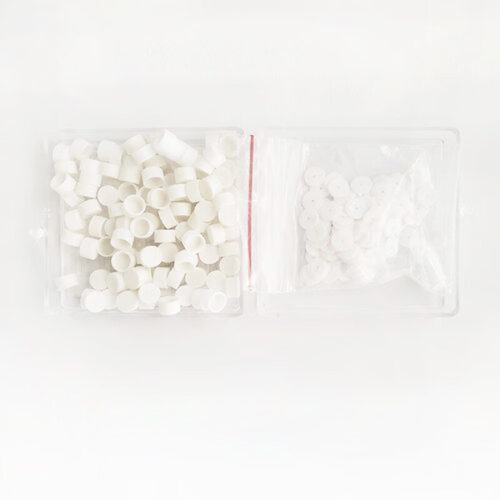

High Purity Alumina Sample Pan for TGA and DSC

Introduction:

High-purity alumina sample pans for TGA and DSC are sample support devices for these thermal analysis techniques, typically made of high-purity alumina ceramic.

These sample pans are employed for containing samples and enduring high temperatures during analysis, possessing good chemical inertness to ensure accurate thermal analysis results. They are suitable for various high-temperature thermal analysis techniques such as thermogravimetric analysis, differential scanning calorimetry, and calorimetry.

Features of High-purity Alumina Sample Pans:

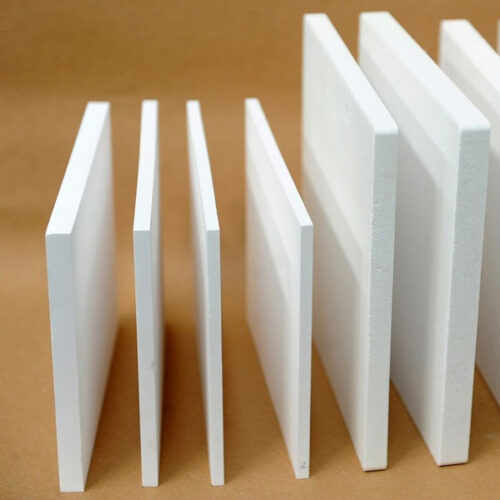

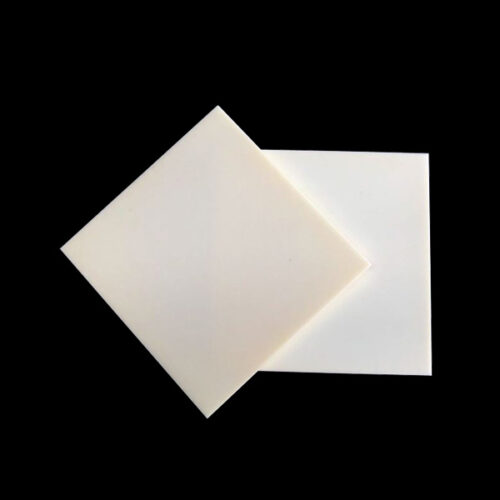

Formulated with high-purity powder and subjected to precise control during high-temperature sintering process, resulting in dense and uniform microcrystalline structure, ensuring no peak deviation during usage and minimal physical or chemical reactions with analytical samples.

Key Features:

1. High temperature resistance: Capable of withstanding temperatures ranging from 1600°C to 1750°C.

2. Chemical inertness stability: With an alumina content of 99.2%, it exhibits high chemical stability, minimizing contamination or interference with most chemicals, thereby preserving sample integrity.

3. High thermal conductivity: Facilitates rapid and uniform heat conduction, aiding in the uniform heating of samples within the crucible.

4. High reusability: After appropriate cleaning and maintenance, it can be repeatedly used for experiments.

Our Offered Specifications for Alumina Sample Pan:

| Specification Table for High-Purity Alumina Sample Pans (UoM:mm) | |||

| (φ5*2.5)25ul | (φ5*3)40ul | (φ5*4)43ul | (φ5*5)56ul |

| (φ6.8*4)67ul | (φ6*4)68ul | (φ6*4.5)78ul | (φ6.5*4)83ul |

| (φ7*4)98ul | (φ5*8)100ul | (φ9*4)130ul | (φ6.5*8)170ul |

| (φ6.5*10)185ul | (φ10*10)0.4ml | (φ12*12)0.8ml | |

| The sample pans are available with and without covers, with wall thickness ranging from 0.5 to 1.4mm. Various specifications are available; for detailed dimensions, please consult our professional customer service team. | |||

Applications:

1. Thermogravimetric analysis (TGA): Used to measure changes in sample mass at different temperatures, including adsorption, loss of weight, and chemical reactions.

2. Differential scanning calorimetry (DSC): Measures the heat released or absorbed during sample heating or cooling processes, as well as changes in sample thermal properties.

3. Thermal analysis: Investigates sample decomposition and pyrolysis processes at high temperatures to determine material stability and decomposition products.

4. Material research: Evaluates thermal properties, thermal stability, and thermal decomposition behavior of different materials to guide the development and application of new materials.

5. Drug development: Evaluates the thermal performance and stability of drugs to ensure their safety and efficacy.

Alumina Sample Pan Usage Precautions:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute. When cooling, it is recommended to control the temperature by powering off gradually. Cooling too fast during the initial cooling phase after turning off the power may cause the product to crack.

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.