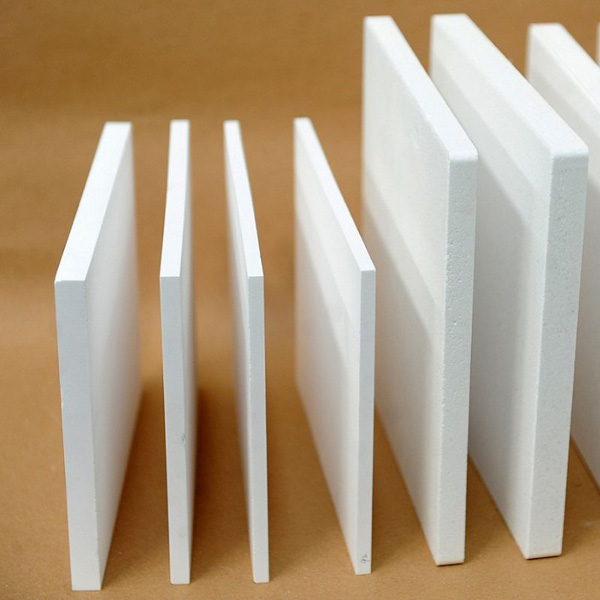

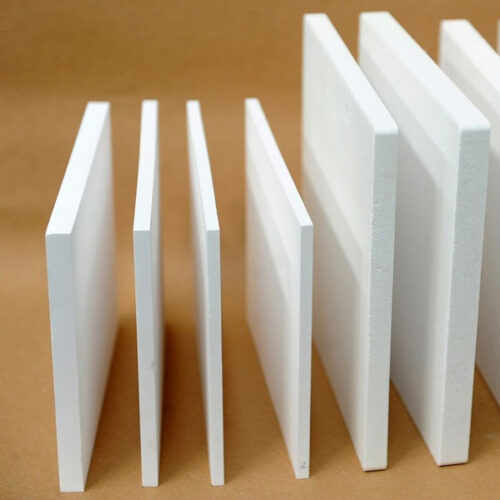

High Purity Ceramic Alumina Plate

Introduction:

The high purity ceramic alumina plate is a type of board made from high purity aluminum oxide, typically possessing extremely high purity and excellent physical and chemical properties.

During the manufacturing process of this type of plate, high-temperature sintering processes are commonly employed to ensure the density and robustness of the crystal structure.

High purity ceramic alumina plates are primarily used in fields where high demands are placed on purity, chemical stability, and wear resistance, such as electronics, aerospace, chemical engineering, and medical applications.

Manufacturing Process:

1、Making abrasives

2、Making blanks

3、Firing blanks

4、Storage after passing inspection

Advantages:

1. The product material is 99% alumina (Al2O3 > 99%) or 95% alumina (Al2O3 > 95%), with high purity.

2. Adopting slip casting/pressing molding process.

3. Firing temperature is 1800°C, long-term use temperature ≤ 1600°C.

4. High temperature resistance and chemical corrosion resistance.

Our Offered Specifications for Alumina Plate:

| Alumina Plate Specification Table (UoM:mm) | |||

| 50×25×3 | 200×100×8 | 100×100×4 | 100×100×10 |

| 115×70×10 | 130×32×10 | 133×133×6 | 140×85×10 |

| 150×100×10 | 150×140×8 | 160×160×8 | 250×250×10 |

| We also offer a variety of other sizes of alumina plates. For detailed specifications, please consult our professional customer service representatives. | |||