Laboratory Heat Treatment Alumina Kiln Furniture | Furnace Shelves

Product Description:

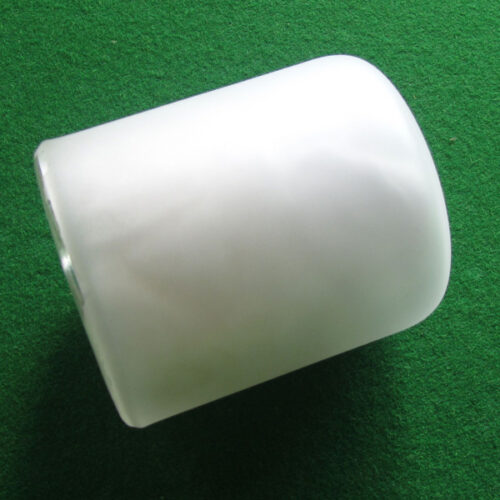

Alumina kiln furniture is made from high-purity alumina (Al₂O₃) and is specifically designed for use inside furnaces, particularly in high-temperature applications.

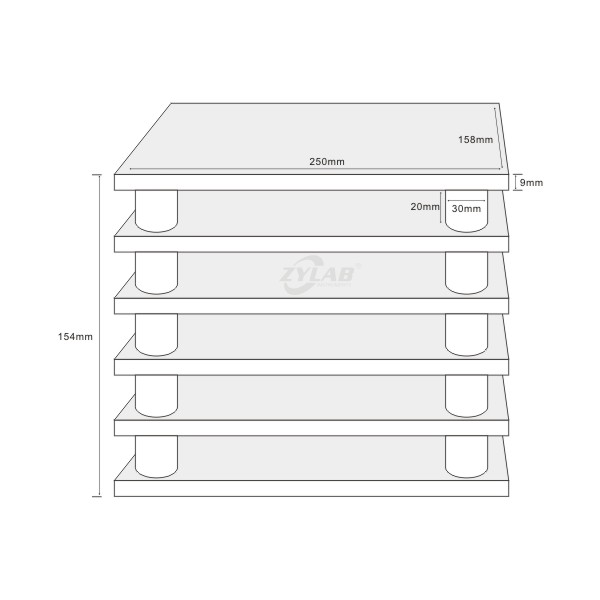

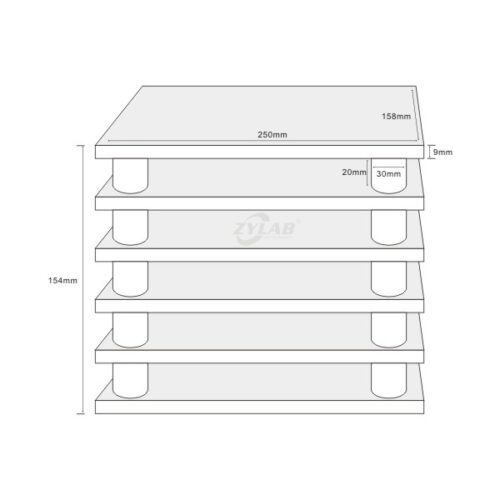

Kiln racks typically feature two or more layers, designed based on the number of samples being processed and the size of the furnace chamber. The height between each shelf can also be adjusted according to specific needs.

Alumina Purity: >99%

Maximum temperature resistance: 1750°C

Continuous operating temperature: ≤1600°C

Product Features:

Material Composition: Made from over 99% pure alumina, ensuring excellent thermal stability and minimal contamination of processed materials.

High-Temperature Resistance: Capable of withstanding extreme temperatures up to 1750°C, suitable for various high-temperature applications.

Surface Finish: The alumina shelves are finely processed to ensure a smooth surface, promoting heat distribution and reducing the risk of contamination.

Customizable Sizes and Shapes: Available in various sizes and configurations to fit different furnace designs and operational needs.

Standard Products and Specifications:

| Alumina trays Specification (UoM:mm) | |||

| 20×20×1.5 | 45×23×3 | 150×25×3 | 50×30×3 |

| 50×40×3 | 50×50×3 | 60×30×3 | 60×40×3 |

| 60×50×3 | 60×60×3 | 65×65×3 | 70×70×3 |

| 75×75×4 | 80×40×4 | 80×80×4 | 84×75×8 |

| 85×85×4 | 90×60×3 | 90×90×4 | 100×30×3 |

| 100×40×3 | 100×40×6 | 100×40×9 | 100×50×3 |

| 100×50×9 | 100×60×3 | 100×100×3.5 | 100×100×5 |

| 100×100×7 | 100×100×8 | 105×105×4 | 110×110×4 |

| 115×55×3 | 115×65×4 | 115×115×4 | 120×80×5 |

| 120×120×6 | 130×130×6 | 140×140×6 | 150×130×7 |

| 150×150×6 | 150×150×7 | 155×40×4 | 160×120×5 |

| 160×140×5 | 160×160×6 | 180×180×6 | 200×100×6 |

| 200×150×5 | 200×200×8 | 220×220×8 | 250×155×9 |

| 250×250×7 | 160×140×9 | 320×320×6 | 330×330×15 |

Trays are available for purchase separately.

| Alumina columns Specification (UoM:mm) | |||

| Square Type | |||

| 4*4*4 | 4*4*6 | 4*4*7 | 5*5*3 |

| 5*5*4 | 5*5*5 | 5*5*7.5 | 15*10*8 |

| 15*10*10 | 19*9*6 | 20*15*12 | 20*20*20 |

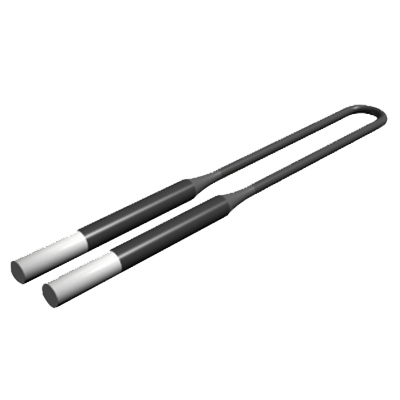

| Cylinder Type | |||

| Ф8*6 | Ф18*15 | Ф30*20 | Ф35*13 |

| Ф35*20 | |||

The above alumina trays and columns dimensions are standard sizes; other sizes can be customized upon request.If you need more detailed information, please contact us immediately. We offer free quotes on all products!

Applications :

Ceramic Processing: Used in the firing and sintering of ceramic materials, providing stable support for even heat distribution during high-temperature processes.

Metallurgical Industry: Ideal for metal refining and heat treatments, supporting metals and alloys during melting, annealing, and sintering.

Glass Production: Employed in the manufacturing of glass, especially in processes like melting and annealing, where precise temperature control is essential.

Materials Science Research: Widely used in laboratory heat treatments, such as sintering and calcination, allowing researchers to study material behavior under high temperatures.

Chemical Processing: Suitable for high-temperature chemical reactions and thermal treatments where alumina’s resistance to chemical corrosion and extreme temperatures ensures stability.

Thermal Analysis: Often used in thermal analysis furnaces, where they support samples undergoing heating, cooling, or chemical reactions in studies like differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA).

Precautions for Using Alumina Kiln Furniture:

Avoid Rapid Temperature Changes: To prevent cracking or damage from thermal shock, avoid sudden temperature changes. Both heating and cooling should be done gradually.

Proper Loading: Ensure that samples and kiln furniture are evenly distributed to avoid overloading or imbalance, allowing for uniform heating and prolonged kiln furniture lifespan.

Prevent Chemical Reactions: Avoid contact between alumina kiln furniture and strong acids, alkalis, or other reactive chemicals to prevent corrosion or sample contamination.

Regular Inspection: After extended use at high temperatures, regularly inspect the kiln furniture for cracks, wear, or deformation, and replace any damaged pieces promptly.

Cleaning and Maintenance: Clean the kiln furniture after use to remove any residues or impurities, ensuring they don’t affect the next experiment or production process.

Temperature Limits: Ensure that the kiln furniture is used within its designated temperature range, typically up to 1750°C, to prevent failure or degradation of its performance.

Proper Equipment Fit: Choose kiln furniture that matches the size and design of the muffle furnace or other high-temperature equipment to optimize performance and efficiency.