High purity Alumina Furnace Furniture Set

Introduction:

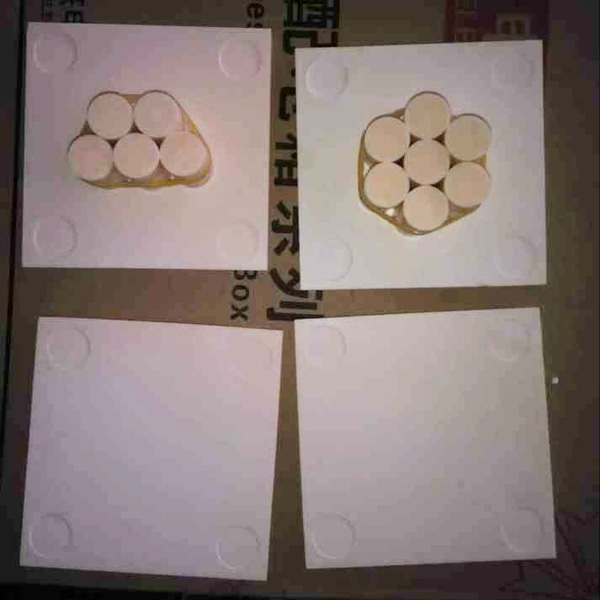

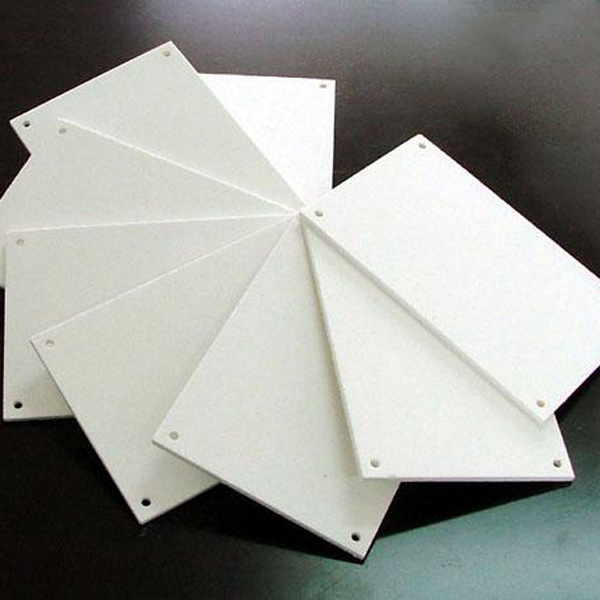

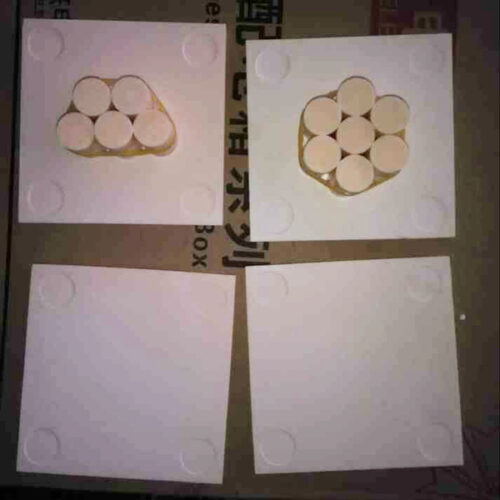

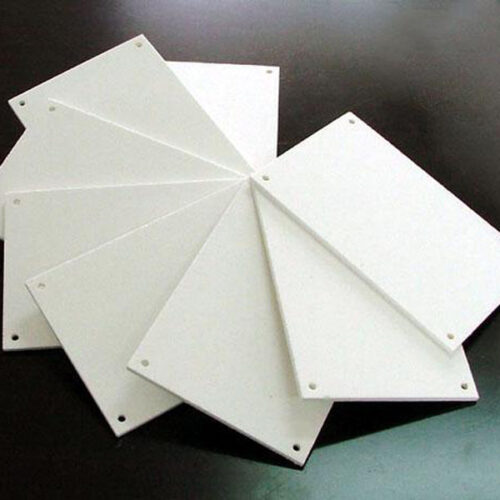

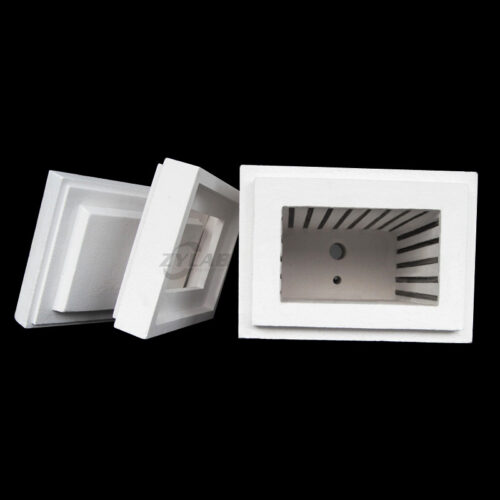

High purity alumina furnace furniture set refers to a collection of furnace furniture components made of high-purity alumina material. This includes various trays, supports, ceramic plates, columns, etc., used to support and contain the materials to be processed and to heat or treat them under high temperature conditions.

Advantages of high-purity alumina furnace furniture:

1. The material of the product is 99% alumina (Al2O3 > 99%), with high purity.

2. Adopting slip casting/pressure molding technology.

3. Firing temperature is 1800°C, long-term use temperature ≤1600°C.

4. High temperature resistance and chemical corrosion resistance.

Functions of alumina furnace furniture set:

Supporting and positioning materials:

One of the main functions of furnace furniture is to support and position the materials or products to be processed. They provide a stable platform, ensuring that the materials can maintain the desired shape and position during the heating process.

Conducting heat:

They can serve as a medium for heat conduction, transferring heat from the heat source to the materials to be processed. This helps achieve uniform heating and ensures that the materials can maintain a stable temperature throughout the process.

Preventing adhesion and deformation:

Special coatings or materials on the surface can prevent the materials being processed from adhering to the surface of the furnace furniture or deforming at high temperatures, thus protecting the surface quality and shape of the materials.

Improving production efficiency:

Through reasonable layout and design, multiple products can be processed simultaneously or processing speed can be increased, thereby reducing costs and increasing output.

Related Furnaces:

Related Furnace Furniture:

Precautions for the use of high-purity alumina furnace furniture:

Avoid collisions and damage: Extra care should be taken during handling, installation, and use to prevent collisions and friction between furnace furniture, thereby avoiding damage.

Pay attention to temperature changes: Avoid sudden temperature changes that may cause furnace furniture cracking or stress concentration, affecting its service life and performance.

Regular cleaning and maintenance: Regularly clean the surface of the furnace furniture to ensure it is in good working condition.

Avoid contamination: High-purity alumina furnace furniture are usually used to process materials requiring high purity, so it is necessary to avoid contact between the furnace furniture and other impurities or chemicals to prevent material contamination.

Proper storage: When not in use, the furnace furniture should be properly stored to avoid moisture, heat, or other environmental factors.

Select appropriate furnace furniture according to production needs: Choose suitable alumina furnace furniture according to specific production processes and requirements. Furnaces furniture of different shapes, specifications, and materials are suitable for different processes.