Alumina (Al2O3) Crucible With Lid, Arc, High Purity

Product Details:

ZYLAB alumina crucible with lid are made from high purity alumina (Al₂O₃) with a purity greater than 99%, capable of withstanding temperatures up to 1750°C. They are widely used in laboratories for material analysis, chemical reactions, and heat treatments, as well as in industries such as ceramics, metallurgy, and glass production.

The arc shaped design enhances the structural integrity of the crucible and allows for more effective heat circulation, making it particularly suitable for melting, sintering, and other high-temperature processes.

The included lid helps to minimize contamination, maintain sample integrity. Under high-temperature conditions, the lid can reduce material evaporation losses and better retain heat, improving heating efficiency.

Covers are available for purchase separately.

Alumina Purity: >99%

Maximum temperature resistance: 1750°C

Continuous operating temperature: ≤1600°C

Custom services such as drilling, engraving, and slotting are available.

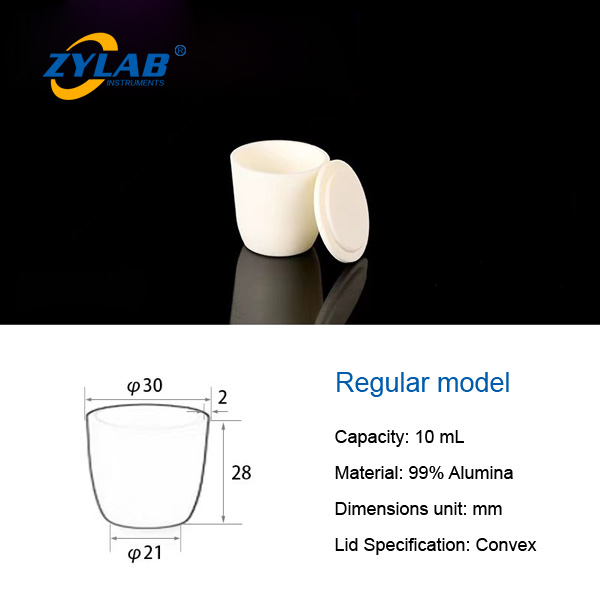

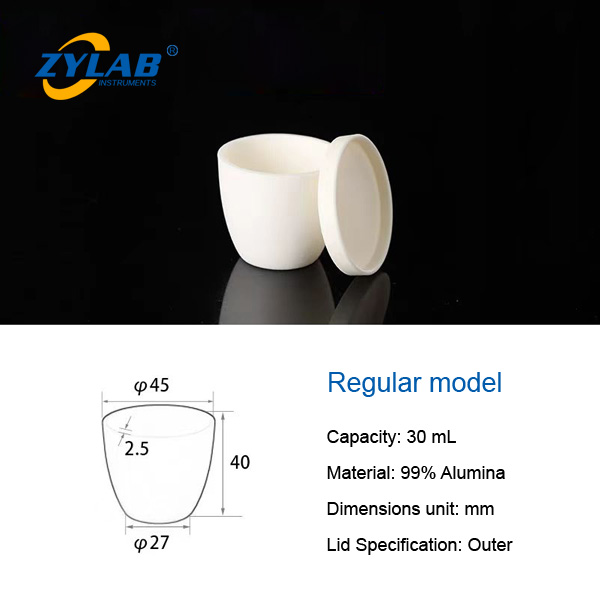

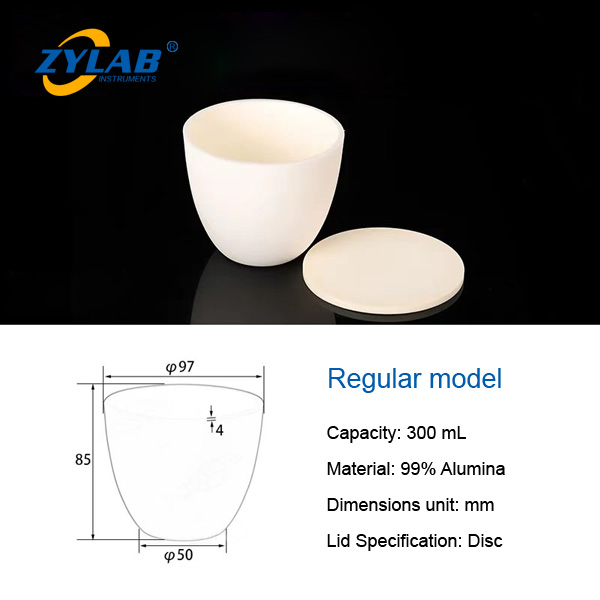

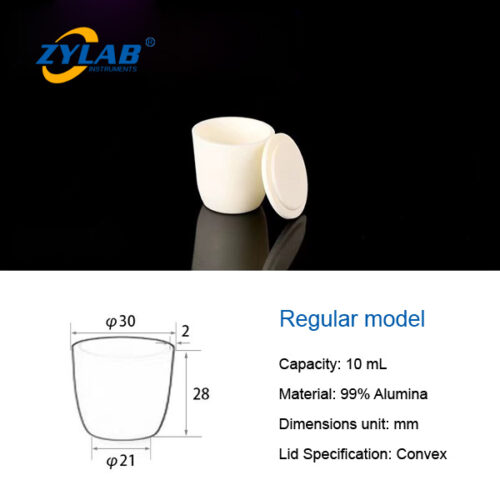

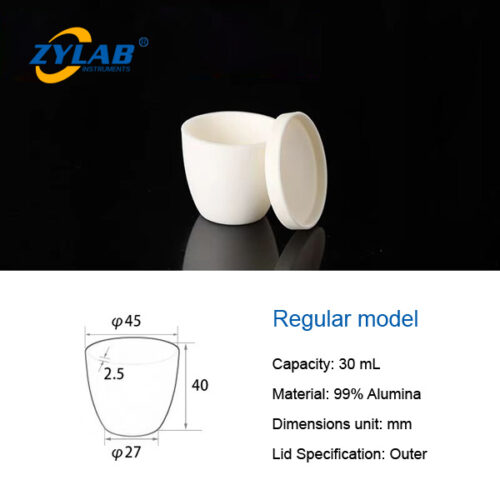

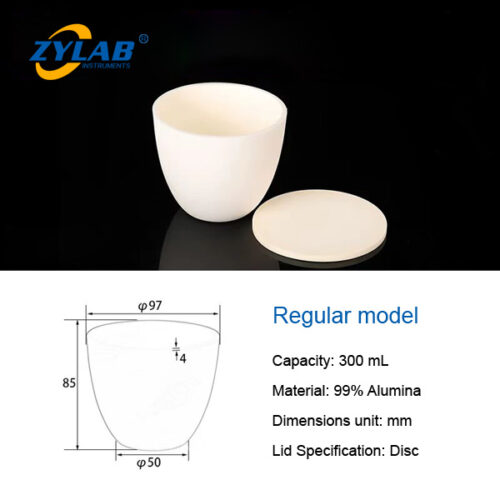

Standard Products and Specifications:

| Specification of Alumina Crucible With Lid | ||||||

| 3ml | 4ml | 5ml | 10ml | 15ml | 20ml | 25ml |

| 30ml | 40ml | 50ml | 100ml | 150ml | 200ml | 300ml |

| 350ml | 460ml | 500ml | 750ml | 1000ml | 1300ml | 1500ml |

| 2300ml | ||||||

| The crucibles come in both standard and heightened models. There are three types of lids: inner dome lid, outer wrap lid, and flat disc lid. | ||||||

The above alumina crucibles dimensions are standard sizes; other sizes can be customized upon request.If you need more detailed information, please contact us immediately. We offer free quotes on all products!

Applications:

Material Analysis: Used in laboratories for high-temperature experiments to analyze the properties of materials, including thermal stability and chemical reactivity.

Chemical Reactions: Ideal for conducting various chemical reactions under controlled conditions, the lid minimizes contamination and helps maintain a stable environment.

Melting and Sintering: Suitable for melting metals and alloys or sintering ceramic materials, providing efficient heat distribution due to its arc shape.

Heat Treatment: Employed in heat treatment processes for materials to improve their mechanical properties and structural integrity.

Ceramics Production: Commonly used in the ceramics industry for firing ceramic products, ensuring high purity and quality in the final output.

Metallurgy: Essential in metallurgical processes for sample preparation and testing, including alloy production and refining.

Glass Production: Used in the production of specialty glasses, the crucible can withstand the high temperatures required for melting glass materials.

Research and Development: Facilitates experimental setups in R&D for developing new materials or processes, where high purity and temperature resistance are critical.

High Purity Alumina Crucibles Notes for Use:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute. When cooling, it is recommended to control the temperature by powering off gradually. Cooling too fast during the initial cooling phase after turning off the power may cause the product to crack.

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

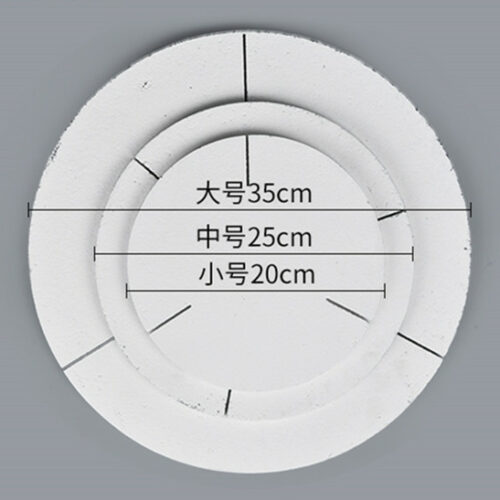

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.