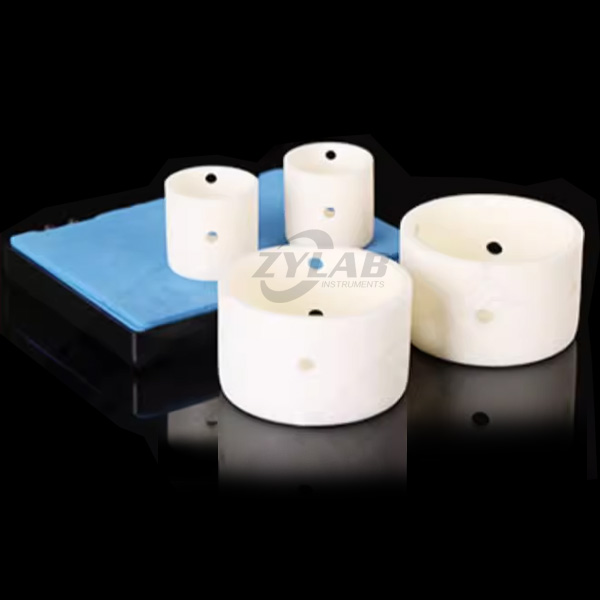

Alumina (Al2O3) Crucible with Hole

Product Details:

Alumina crucible with hole is usually customized with openings added to the original crucible structure. It is used in high-temperature experiments and industrial processes to meet specific requirements, such as gas flow, sample ventilation, material reaction monitoring, or facilitating certain heat treatment processes.

ZYLAB alumina crucibles are made from high purity alumina (Al₂O₃) with a purity greater than 99%, capable of withstanding temperatures up to 1750°C.

Alumina Purity: >99%

Maximum temperature resistance: 1750°C

Continuous operating temperature: ≤1600°C

Custom services such as engraving, and slotting are available.

If you need more detailed information, please contact us immediately. We offer free quotes on all products!

Use Alumina Crucible with Hole:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute.

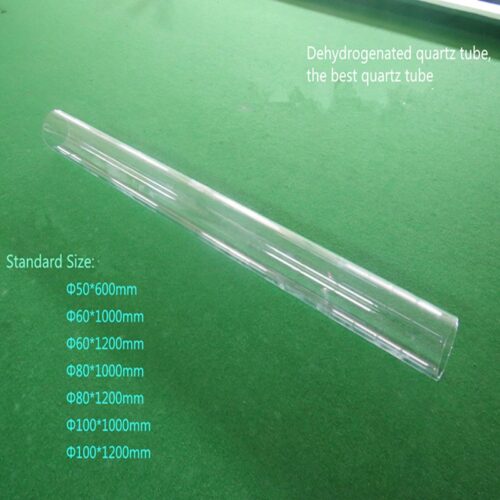

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.