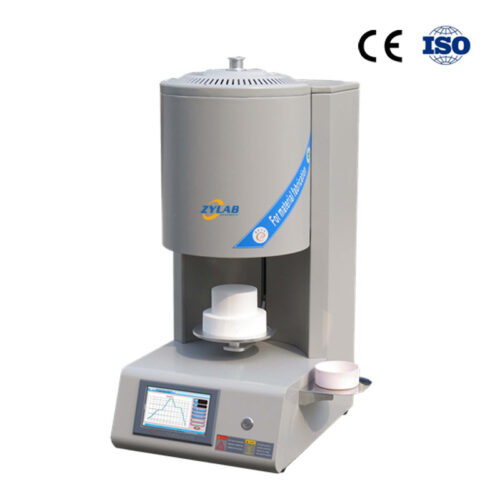

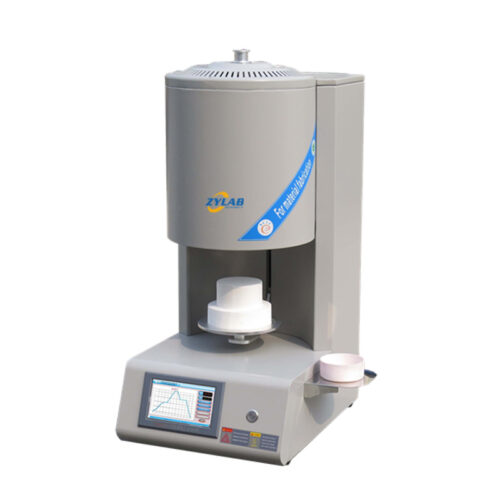

Air-Jet Sieving Machine for Sieving Analysis of Low-density and Easily Agglomerated Fine Particles

Introduction:

The Air-Jet Sieving Machine uses aerodynamic sieving technology to prevent agglomeration, ensuring excellent sample dispersion. It is specifically designed for sieving analysis of low-density and easily agglomerated fine particles. It is compatible with analysis sieves with apertures of 10 microns and above. The sieve mesh undergoes special non-metallic treatment, and the nozzle speed is adjustable, providing flexible sieving with an average sieving time of 2-3 minutes. It can be used with manually adjustable industrial suction equipment or optional automatic suction equipment. The continuous airflow ensures the repeatability of the sieving process and consistent sieving results.

Features and Benefits of Air-Jet Sieving Machine:

- Utilizes air jet technology to reduce small particle agglomeration.

- Can store 9 types of SOP modes.

- Compatible with standard analysis sieves of 203mm (8″) or 200mm (with adapter), 1″ or 2″ high.

- Manual operation (standard) / automatic pressure regulation (optional).

- EasySieve software is optional, allowing control through RS232 serial interface for easy measurement and recording of sieving results.

- Adjustable parameters include time, negative pressure, and nozzle speed.

- Can be connected to a vacuum cleaner to create a negative pressure environment.

- Simple operation and maintenance-free.

- Integrated silencer for noise-free operation.

- Non-metallic treated sieve mesh.

Technical Parameters of Air-Jet Sieving Machine:

| Model | JS-200 | ||

| Applicable Particle Size | 3um~4mm | Open Mesh Function | 10 (r/min),+20″,-10° |

| Maximum Load | 100g | Suction Equipment | 2000-9999pa/20-99mbar/0.3-1.45psl |

| Maximum Levels | 1 level (2 levels require a cyclone collector) | Dispersion Method | Aerodynamic dispersion |

| Nozzle Speed | 5-55 (r/min) | Analysis Sieve Diameter | 200mm / 203mm |

| Time Setting | 0-99 min | Sieve Tower Height | 25/50mm |

| Storable Parameter Combinations | 9 + Quick Start | Dimensions | 460*288*305mm |

Applications:

The Air-Jet Sieving Machine is widely applicable in various industries for precise particle size analysis and separation. Here are some of its key applications:

- Chemical Industry: Used for the analysis and separation of fine chemical powders, pigments, catalysts, and additives.

- Pharmaceutical Industry: Essential for the quality control of active pharmaceutical ingredients (APIs), excipients, and other fine powders in tablet and capsule production.

- Food Industry: Used for the grading and separation of powdered food products, such as flour, spices, sugar, and starches, ensuring uniform particle sizes for better texture and taste.

- Paper Industry: Applied in the analysis of pulp and paper coatings, fillers, and additives to maintain the desired quality and consistency.

- Metallurgy: Utilized for particle size analysis of metal powders, ores, and mineral samples in metallurgical processes.

- Building Materials: Used for the sieving of cement, gypsum, sand, and other construction materials to ensure consistent particle distribution and quality control.

- Rubber and Plastics Industry: Suitable for the analysis of fillers, additives, and powdered materials used in rubber and plastic production.

- Mechanical and Engineering Industry: Employed for quality assurance in the production of precision components requiring specific particle sizes.

- Cosmetic Industry: Used for sieving fine powders, such as talc and cosmetic pigments, to ensure smooth textures and consistent quality.

For More Sample Preparation Solutions

Please visit our website [Sample Preparation Collection]