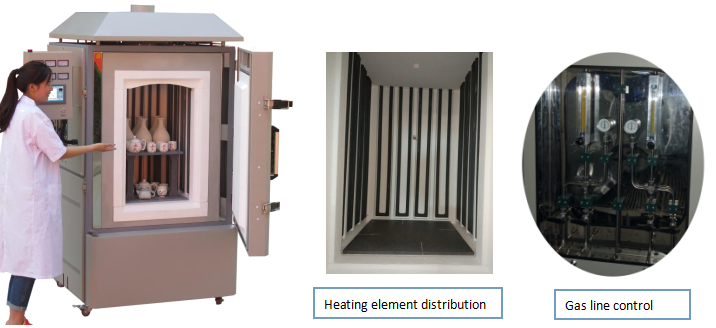

640L 1500°C Chamber Furnace with Inert Gas Atmosphere System

Introduction

This 640L 1500°C Chamber Furnace offers a sufficiently large sintering chamber, making it suitable for laboratory research as well as industrial production.

It is mainly used in industries such as electronic components, artistic ceramics, structural ceramics, thick film circuits, magnetic materials, and metal heat treatment.

Based on the standard chamber furnace design, this product incorporates a pipeline system that delivers protective gas into the furnace chamber, creating an inert atmosphere for high-temperature sintering or heat treatment processes.

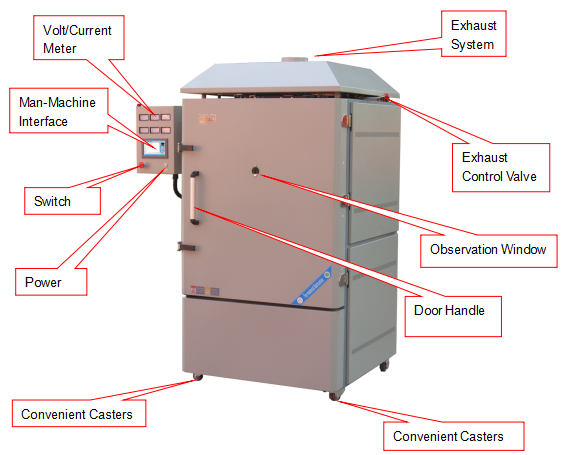

Structure of High Temperature Chamber Furnace

Key Features:

- High-Temperature Performance: Maximum temperature of 1500°C, with a continuous operating range from room temperature to 1450°C.

- Advanced Programmable Control: Features a 30-segment programmable controller for precise temperature management and automated operation.

- Efficient Heating & Energy Saving: The ceramic fiber furnace chamber ensures rapid heating while reducing power consumption.

- Superior Lining & Heating Elements: Incorporates special lining and high-purity heating elements, effectively preventing chemical contamination and enhancing durability.

- Safe & Cool Exterior: The double-layer steel casing with fan cooling keeps the outer surface temperature below 50°C, ensuring operator safety.

- Dual Atmosphere Control: Equipped with a two-way atmosphere system, supporting inert gases such as Nitrogen, Argon, etc.

- Effective Exhaust System: A top-mounted exhaust chimney efficiently removes volatiles generated during sintering.

- Modern & Practical Design: Features a sleek, innovative appearance combined with practical functionality.

Technical Specifications:

| Model | M1500

640L 1500°C Chamber Furnace |

| Furnace Structure | •1600 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

800(W)x1000(H)x800(D)mm(640L) |

| Max Working Temperature | 1500°C |

| Continue

Working Temperature |

RT~ 1450°C |

| Heating Elements | Special high-density and high-purity silicon carbide rod with excellent acid and corrosion resistance, 3 sides heating

|

| Intelligent Touch Screen

Temperature controller |

1. PID automatic control and auto-tune function. 2. 30 programmable segments for precise control. 3. Built in protection for over-heated and broken thermal couple, and leakage. 4. Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. 5. Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes.

|

| Working Voltage | 380V 50HZ(or as requirement) |

| Rated Power | 50KW |

| Heating Rate | ≤20℃ |

| Temperature Accuracy | ±1℃ |

| Thermal Couple | S type |

| Temperature Uniform | ±3℃ |

| Warranty | 12 months(not including consumable parts, such as heating elements, thermocouple, etc), lifetime support. |

| Certificate | ISO |

Standard Size and Delivery Time

| Model | Max. temperature | Chamber Size(W*H*D) | Delivery Time |

| M1500-50IT | 1500 degree C | 500*800*500mm | 25 days |

| M1700-50IT | 1700 degree C | 500*800*500mm | 25 days |

| M1500-80IT | 1500 degree C | 800*1000*800mm | 35 days |

| M1700-80IT | 1700 degree C | 800*1000*800mm | 35days |

Which kinds of industry can use this Chamber Furnace?

University, Material Science, New Energy Research, Powder Metallurgy, Ceramic, etc.

Applications of 640L 1500°C Chamber Furnace

-

Electronic Components

- Sintering and annealing of electronic ceramics

- Firing thick-film circuits

-

Structural Ceramics

- High-temperature sintering of alumina, zirconia, and other structural ceramic materials

- Production of wear-resistant and high-strength ceramic parts

-

Magnetic Materials

- Sintering and heat treatment of ferrite and rare-earth magnetic materials

- Improving magnetic properties through precise thermal processing

-

Metal Heat Treatment

- Annealing, hardening, and tempering of metal components

- Debinding and sintering of powder metallurgy parts

- Heat treatment in an inert gas atmosphere to prevent oxidation

-

Artistic and Functional Ceramics

- Firing artistic ceramics and porcelain at high temperatures

- Producing functional ceramic products for industrial use

-

Research and Development

- High-temperature material research in laboratories

- Thermal testing of new materials under controlled atmosphere conditions

-

Industrial Production

- Batch sintering for small-to-medium scale manufacturing

- Suitable for pilot-scale production lines requiring consistent high-temperature performance

For More Options on Chamber Furnaces

Click here [Chamber Furnaces Collection]

For More Options on High Temperature Furnaces

Click here [High Temperature Furnaces Collection]