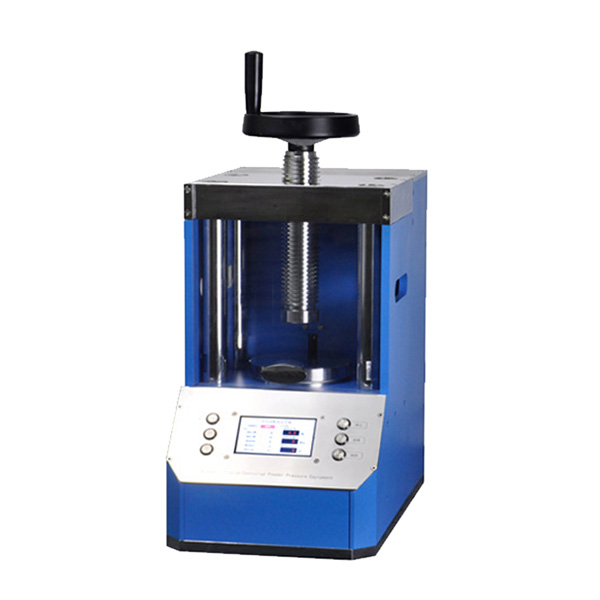

Laboratory 60-ton Automatic Powder Pellet Press with Safety Shield

Introduction:

The 60-ton automatic powder pellet press is a new laboratory pellet press developed by our company based on existing manual and electric pellet presses, with the advice and support of some university professors. Equipped with appropriate mold accessories, it is perfect for powder sample pressure forming.

Technical specifications:

| Model | PP-60A |

| Pressure Range | 0-60 tons |

| Oil Cylinder Stroke | 50 mm |

| Display Method | 4.3-inch LCD screen |

| Pressurization Process | Programmed pressurization – Programmed pressure holding – Timed pressure release |

| Pressure Holding Time | 0~999 seconds |

| Pressure Conversion | Mold pressure bearing (MPa), automatically converted and displayed |

| Oil Cylinder

Limit Protection |

Program automatically calculates mold pressure bearing |

| Equipment Protection | Steel plate protection with plexiglass protective door |

| Power Supply | 220V(50Hz/60Hz) |

| Working Space | 185X220mm |

| Overall Dimensions | 300X520X580mm |

| Weight | 180kg |

Features and Benefits:

- New fully automatic design with programmed pressurization, programmed pressure holding, and automatic pressure release, intuitive operation, and attractive appearance, suitable for laboratory use.

- Mold pressure automatically converted and displayed, eliminating the need for manual calculation to prevent mold damage due to operational errors, making operation more user-friendly.

- Equipped with limit protection switch, the oil cylinder automatically releases pressure when reaching the limit height, avoiding machine damage caused by cylinder over-positioning, oil leakage, and other phenomena.

- Large-screen LCD display for more intuitive operation and clearer display, facilitating user setting and operation.

Applications:

Automatic powder pellet presses are versatile tools used in various industries for different applications. Here are some common uses:

- Pharmaceuticals: Creating uniform drug pellets for controlled release and improved bioavailability.

- Chemicals: Compacting powders for catalysts, pigments, and chemical compounds.

- Catalyst Production: Forming uniform catalyst pellets for chemical reactions.

- Food and Beverage: Shaping ingredients like spices and nutritional supplements.

- Cosmetics: Pressing powders for products like eyeshadows and pressed powders.

- Metallurgy: Producing metal powder compacts for sintering.

- Ceramics: Forming green bodies for ceramic components.

- Battery Manufacturing: Compacting electrode materials for batteries.

- Research and Development: Preparing samples for analysis or testing.

- Agriculture: Compressing biomass into pellets for fuel or animal feed.

Others:

Optional- Matching Dry Pellet Pressing Die Set