High-Throughput Intelligent 4 Channel Box Furnace

Introduction:

This equipment is a 1500°C high-throughput 4-channel box furnace. It can be used to heat treat multiple samples using high-throughput methods. Each heating module is controlled by an independent temperature control system, allowing for simultaneous processing of 4 samples at different temperatures.

The furnace is controlled by a PLC and operated via a touchscreen, making it simple and convenient to use.

Features and Benefits of 4 Channel Box Furnace:

- Advanced PID Self-learning Fuzzy Control: High temperature control accuracy, maintaining within ±1°C.

- High-Purity Alumina Lightweight Fiber Liner: Better insulation effect, energy-saving, and consumption reduction.

- IoT Functionality (WIFI): Remote monitoring and operation via mobile phone or computer.

- Data Storage Function: Can save important sintering parameters for up to 30 days (assuming 8 hours of operation per day).

- Recipe Function: Can store more than 20 recipes.

- Networking Function: Through the RJ45 interface and 6. TCP/IP protocol, the system can connect to an upper-level computer (appropriate software needs to be installed on the upper-level computer).

Technical specifications:

| Product Name | 4 Channel Box Furnace | |

| Model | M1500X-MGI-4 | |

| Electrical Specifications | AC380V 50HZ, three phase | |

| Rated Power | 10KW | |

| Sensor Type | S-type thermocouple, 220mm | |

| Max.working Temp | 1450℃ | |

| Continuous Working Temperature | 1300~1400℃ | |

| Temperature Accuracy | +/- 1℃ | |

| Recommended Heating Rate | 5℃/Min | |

| Heating Zone Dimensions | 120*120*120mm | |

| External Dimensions | Length 850 mm (excluding cantilever box) × Height 1580 mm × Depth 600 mm | |

| Net Weight | Approximately 280KG | |

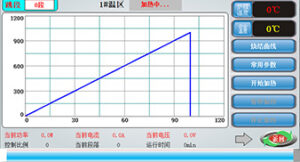

| Control System |

|

|

| Furnace Details | Furnace Chamber

|

|

| Process & Mechanical Control Interface |

|

|

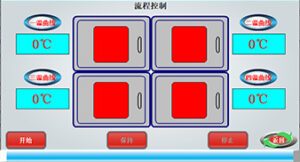

| Process & Recipe Library Interface |

|

|

| Service Support | 1-year warranty with lifetime support. | |

Applications:

The 4-channel box furnace is designed for sintering, chemical vapor deposition, and other processes for ceramics, metallurgy, electronics, glass, chemical industry, machinery, refractory materials, new materials development, special materials, building materials, metals, non-metals, and other compound materials. It is suitable for higher education institutions, research institutes, and industrial and mining enterprises.