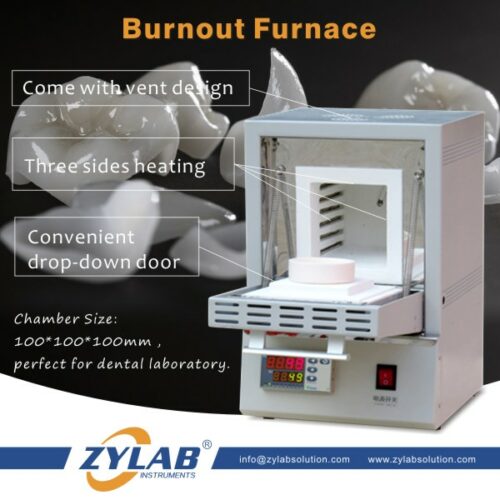

Intelligent 1200.C 4.5L Burnout Furnace

Introduction:

This Burnout Furnace is special design for customers, ultra-high cost performance of 4.5L volumetric electric furnace.

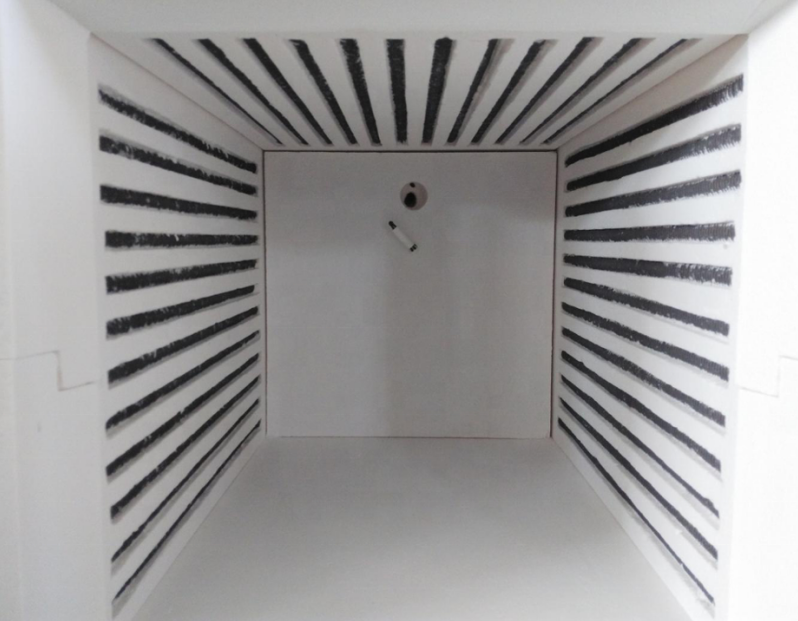

Use classical simplified design process, multi-layer alumina fiber furnace chamber, touch screen controller, accessible man-machine interaction, make operation easier!

The latest technology of molybdenum-doped iron-chromium-aluminum alloy heating wire. With the exhaust device, not only can be used for routine use, but also for wax burnout and ashing experiments.

Main Features:

1. Max. Temperature 1200C, working temperature RT-1100C.

2. Intelligent 7” color touch screen temperature controller, easy to operate, clear heating process; can store temperature curve to avoid the trouble caused by repeated settings of different experimental processes.

3. 30 segments programmable and auto control.

4. Ceramic fibre furnace chamber, to ensure a fast heating rate, and save power.

5. By using special lining import from Japan and high quality alloy heating wire with excellent acid and corrosion resistance, protected against chemical contamination at the best and longer service life.

6.With the exhaust device(an exhaust chimney in the top of the furnace), not only can be used for routine use, but also for wax and ashing experiments.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

8. Low power consumable, exquisite structure and light weight, it is the ideal burnout furnace for material research labs, also used in factory production.

Main Specifications:

| Model | M1200-15IT |

|

Furnace structure |

•1430 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

150*150*200mm(4.5L) |

| Max. temperature | 1200.C(<1 hours) |

| Working temperature | Rt -1150.C |

| Intelligent Touch Screen

Temperature controller |

•PID automatic control via SCR. •30 programmable segments for precise control of heating rate, cooling rate and dwell time. •Build in PID auto-tune function with overheating and broken thermocouple broken protection, over temperature protection and alarm allows for operation without attendant. •Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. •Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes. |

| Heating element | High Quality Fe-Cr-Al Wire |

| Heating rate | 0~20.C/min |

| Temperature accuracy | +/- 1.C |

| Thermocouple | K type |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) |

| Max. Power | 3 Kw |

| Dimension | 390(W)*600(H)*430(D)mm |

| Quantity / Net weight | 1set / 40kgs |

| Warranty | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. |

| Certificate | CE, ISO9001 |

Applications:

Burnout furnaces are essential equipment in various industries, primarily in the field of manufacturing and processing materials, especially those involving metals, ceramics, and jewelry. Here are some common applications of burnout furnaces:

Jewelry Making

In jewelry manufacturing, burnout furnaces are used for the casting process. Wax patterns of the jewelry pieces are invested in a mold material, and then the mold is placed in the burnout furnace to melt away the wax (hence, the term “burnout”), leaving behind a cavity in the mold where molten metal can be poured.

Dental Laboratories

Burnout furnaces are crucial in dental laboratories for the fabrication of dental prostheses, such as crowns, bridges, and implants. Similar to jewelry making, the wax patterns of dental restorations are invested in molds and then subjected to the burnout process to create voids in the mold for casting dental alloys.

Ceramics Production

In ceramic manufacturing, burnout furnaces are used for the production of investment casting molds. Wax patterns are coated with a ceramic slurry to form a shell, and then the wax is melted out in the burnout furnace, leaving a cavity in the shell where molten metal can be poured to create ceramic parts with intricate details.

Metal Casting

Burnout furnaces are employed in metal casting processes for both artistic and industrial applications. They are used to remove organic materials, such as wax or plastic, from investment molds before metal casting. This ensures that the molds are clean and ready to receive molten metal, resulting in high-quality castings.

Prototype Development

Burnout furnaces play a vital role in rapid prototyping and small-scale manufacturing industries. They are used to create precise and intricate prototypes of various products, including engineering components, consumer goods, and medical devices, by casting them in metal or ceramic materials.

Research and Development

Burnout furnaces are utilized in research and development laboratories for experimenting with new materials and processes. Researchers may use them to fabricate prototypes, test new casting techniques, or study the effects of different parameters on the quality of castings.

Artistic Foundries

In artistic foundries and studios, burnout furnaces are used by sculptors and artists to create metal sculptures and artworks through the lost-wax casting process. The burnout furnace ensures that the wax models are completely removed from the molds before metal casting, allowing artists to achieve intricate details and textures in their creations.

Educational Institutions

Burnout furnaces are commonly found in educational institutions, such as universities and technical schools, where they are used for teaching purposes in courses related to manufacturing, materials science, and engineering. Students learn about casting processes and gain hands-on experience in operating burnout furnaces as part of their curriculum.

Overall, burnout furnaces play a critical role in various industries and applications where precision casting of metal or ceramic parts with intricate details is required. They facilitate the production of high-quality components, prototypes, and artworks while ensuring efficiency and repeatability in the manufacturing process.

Benefits of Burnout Furnace:

Burnout furnaces offer several benefits across various industries and applications. Here are some of the key benefits:

Precision Casting

Burnout furnaces ensure the thorough removal of wax or other organic materials from investment molds before casting. This results in precise and accurate replication of intricate details, leading to high-quality finished products.

Improved Quality

By eliminating contaminants from the mold, burnout furnaces help prevent defects such as porosity, shrinkage, and surface irregularities in the castings. This leads to higher-quality and more consistent cast parts.

Versatility

Burnout furnaces can accommodate a wide range of materials, including metals, ceramics, and resins. This versatility makes them suitable for various applications, including jewelry making, dental prosthetics, aerospace components, and art casting.

Cost-Efficiency

The use of burnout furnaces reduces material wastage and rework by ensuring clean molds and minimizing casting defects. This results in cost savings associated with scrap reduction and increased productivity.

Time Savings

Burnout furnaces are designed for efficient operation, with precise temperature control and rapid heating capabilities. This leads to shorter cycle times for the burnout process, allowing for faster production turnaround times.

Ease of Operation

Modern burnout furnaces are equipped with user-friendly controls and automation features, making them easy to operate and maintain. This reduces the need for specialized training and minimizes the risk of operator errors.

Environmental Friendliness

Burnout furnaces are designed with energy-efficient features to minimize energy consumption.

Consistent Results

Burnout furnaces offer consistent and repeatable results, ensuring uniformity in the properties and dimensions of cast parts. This consistency is essential for meeting quality standards and specifications in various industries.

Overall, the use of burnout furnaces provides numerous benefits, including improved quality, cost-efficiency, versatility, and environmental friendliness, making them indispensable tools in the casting process.